Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Do you want to change a block of metal into a helpful part? Do you want to do it with great accuracy? Do you want to tell a powerful machine exactly what to do? That is what CNC programming is all about. It is the language that lets you talk to a CNC machine. This guide is made for someone who is just starting. You will learn the first steps. We will go from a basic idea to a finished item. We will explain this tricky subject in a simple way. This is your first step to get good at a useful skill. This skill is important in making things today.

First, let’s talk about the machine itself. A CNC machine is a tool run by a computer. CNC stands for Computer Numerical Control. You can think of it like a very smart and strong robot. In the old way of doing things, called manual machining, a person with a lot of skill had to turn wheels. They also had to pull levers to cut the materials. The operator controlled every single move the machine made.

Doing this by hand needed a lot of skill. You also had to pay close attention to the small details. Every part was a little different. A CNC machine changes all of that. This machine does not use hand controls. Instead, it follows a list of instructions from a computer. These instructions, called a CNC program, tell the machine exactly where to move. They also tell it how fast to go and what to do. This lets the machine do its work all by itself. It can cut and shape metal, plastic, or wood. It does this with amazing accuracy. This way of making things is used in many places that build products. For example, it is used in the aerospace field and for making phone cases. The machine can make the same part a thousand times, and each one will be just right. This is the power of a computer-controlled machine.

Now you have an idea of what the machine does. So what is CNC programming? It is the job of writing the directions for the CNC machine. You are the programmer. You make a computer file with code. This file is like a set of plans for the machine. This code tells the machine every single step it needs to take.

It is very similar to computer programming. But you are not making software. You are making a real object you can hold. The machine reads your directions. Then it does the cutting and shaping jobs. For a beginner, the idea of writing code can sound very hard. But you do not need to worry. This guide to CNC is here to help you start learning. The job of programming can be split into easy steps. You start with an idea or a simple drawing. Then, you use software to turn that idea into a language the machine can understand. This guide to CNC programming will show you how to do these steps. You will learn how to make the machine create the exact shape you want.

There are two main ways you can talk to a CNC machine. The first way is also the most common. It is using G-code. The second way is called conversational programming. Each way of programming has good things and bad things about it. A good programmer knows which one to use for each job.

G-code is the main language for almost every CNC machine. It is a list of codes. These codes start with the letter ‘G’ or ‘M’. Each code is a special instruction. For example, G00 tells the machine to move as fast as it can. G01 tells the machine to move in a straight line at a speed you choose. When you write G-code by hand, you get complete control over the machine. It is great for making parts that are very detailed. But, writing a long program by hand can take a lot of time.

Conversational programming is an easier choice to use. It is often built right into the control panel of the CNC machine. Instead of writing lines of code, the operator or programmer just answers questions on a screen. The machine will ask for the shape, the size, and the kind of cut you want. Then, the machine writes the G-code program for you. This conversational way is great for jobs that are not too hard. It is a wonderful way for a beginner to learn.

| Feature | Manual G-Code Programming | Conversational Programming |

|---|---|---|

| How Easy to Use | Harder for someone new | Very easy, uses menus |

| How Much Control | A lot of control over the machine | Less control, only has the machine’s choices |

| Speed for Easy Jobs | Takes longer to write | Quicker for easy shapes |

| Best For… | Detailed parts, special jobs | Fast single jobs, learning |

Think about giving someone directions to your house. You would use words like “left,” “right,” “forward,” and “back.” A CNC machine also needs directions. But it uses a math map called a coordinate system. This system is like a grid drawn over the machine’s work area. The one used most often is the Cartesian coordinate system. It uses an X, Y, and Z axis. This helps the machine find any spot in a 3D space.

Every direction in your CNC programming tells the cutting tool where it should go on this grid. For example, a command might say, “Move the tool to coordinate X5, Y10.” The machine knows exactly where that spot is. If you do not understand the coordinate system well, you cannot program a CNC machine. Every shape, hole, and cut is described by its points on the grid. Getting this part right is the first step to making a good part. The machine needs this map of shapes to work correctly.

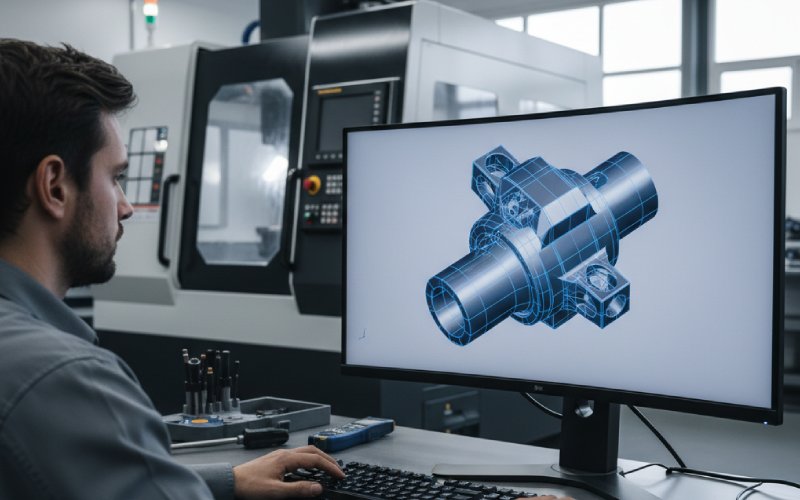

Before you tell a machine how to make something, you must have a plan. In CNC, that plan begins with a drawing on a computer. This is where you use CAD software. CAD stands for Computer-Aided Design. It is a kind of software that helps you create a 2D or 3D model of your part on your computer screen. You can think of it like a very modern drawing board.

A programmer uses CAD software to draw the part. The drawing shows the exact shape and size. With these tools, you can make shapes that are very detailed and tricky. Popular CAD software includes AutoCAD, SolidWorks, CATIA, and products from PTC. This step of making a model is the fun, creative part of CNC programming. It lets you design your part on the computer. You can make it perfect before you cut any real material. Once the 3D model is done, you are ready for the next step.

This 3D model from the CAD software is the main plan. The machine will use this plan to make the real part. When you get the design right in the CAD step, you save a lot of time. You also stop waste from happening later. You can check every measurement and every angle right there on the screen. This is much easier than finding a mistake after the machine has already started to cut the material.

You have a great 3D model in your CAD software. But how do you change that drawing into directions for the CNC machine? For this, you need another kind of software. This is where CAM software is so important. CAM stands for Computer-Aided Manufacturing. This software is like a bridge. It connects your design to the real machine.

CAM software looks at your CAD model and helps you plan out the machining process. You tell the software which cutting tools to use. You also tell it how fast to cut and how deep the cuts should be. The software then uses this information to figure out the toolpaths. A toolpath is the exact path that the cutting tool will follow to make the shape of the part. Using CAM is a very important part of modern CNC programming. Software converts CAD files into code the machine can read.

After you have set up all the details, the CAM software makes the G-code for you. It writes all the lines of code by itself, which can be hundreds or thousands of lines. This saves a very large amount of time when you compare it to programming by hand. It also lowers the chance of making a mistake. Popular CAM software like Mastercam or the CAM module in CATIA can handle very difficult jobs. It is a very helpful tool for any CNC programmer.

Yes, it is very important. Picking the right cutting tools is one of the most important programming steps. Your CAM software can create perfect toolpaths. But if you use the wrong tool on the machine, you will end up with a bad part. It could even break the tool or damage the machine itself. The tool you choose depends on many things. These include the kind of material you are cutting, the shape you need to make, and how fast you want the machine to work.

There are thousands of different kinds of cutting tools. There are drills to make holes. There are end mills to cut grooves and pockets. And there are special tools for making special shapes. Each tool is made to do a certain job. As the programmer, you have to tell the machine which tool to use for each step of the job. In the CNC program, a “T” code followed by a number tells the machine to get a certain tool.

Making the correct choice is very important. For example, the tool you would use to cut soft plastic is very different from the tool you would use to cut hard steel. A good programmer knows how different tools work. They also know how to use them in the best way. You will learn this with practice, and it is a key skill to get good at when you learn CNC programming. Without the right tool selection, even the very best CNC machine cannot do its job well.

Let’s say you just spent hours writing a program for a tricky part. You put the program into a very expensive CNC machine and you press the “Start” button. All of a sudden, you hear a very loud crash. The tool has hit the part or the device holding it. This is a very costly mistake. The good news is, there is a way to stop this from happening. It is called simulation.

Newer CAM software has a simulation tool. This tool lets you watch a video of your CNC machine. It will run the program on your computer screen. You can see the tool moving around. You can see it cutting the material and making the final shape. This simulation shows you exactly what the machine will do. You can see it all before you run the real machine. It is a very important safety check in the programming process.

While you watch the simulation, you can look for any problems. Does the tool crash into anything it is not supposed to? Is the final shape correct? Are the cutting speeds too fast? You can find and fix these mistakes on the computer, which costs nothing. Fixing them on the real machine can cost a lot of money. You should always simulate your program. It is an easy step that will save you a lot of time, money, and worry.

You have made your toolpaths in the CAM software. You have also run a good simulation. You are almost ready to send your program to the CNC machine. But there is one last, very important software step. This step is called post-processing. Different CNC machines and their controllers speak slightly different types of G-code. A code that works great on one machine might not work at all on another one.

The post-processor is a small tool inside your CAM software. Its job is to change the general toolpath information into the special G-code type that your machine understands. When you are using CAM software to make the code, you will pick a post-processor that is made for your exact CNC machine model. For example, a Haas machine needs a different post-processor than a machine with a Fanuc controller.

This step makes sure that the G-code program will run without any problems on your machine. The post-processing step makes the final text file that has all the G-code. You can then save this file to a USB drive or send it over a network to your CNC machine. If you skip this step, your machine might not understand the commands. This can lead to errors, or the machine might not run the program at all. It is the key link that makes your design and manufacturing work smoothly together.

The machine has its own map system, which is called “machine coordinates.” But you will almost never use it. Instead, you will set up a Work Coordinate System (WCS). The WCS lets you pick a handy “zero point” on your block of material. This point is usually a corner or the center of the part. Setting this up the right way is one of the most important jobs for the machine operator.

The G-code program that you wrote uses this zero point as its starting place. When your code says “G01 X1.0,” it really means “move one inch away from the zero point you have set.” To set the WCS, the operator uses a special probe or a tool by hand to touch the sides of the material. This tells the machine where the part is sitting in its work area. The machine then saves this spot as a work offset, which is usually G54.

Why is this so important? It lets you put your material almost anywhere on the machine’s table and still run the same program. The machine will always know where the “zero” of your part is. For a beginner, learning how to set the work coordinate system is a basic and necessary skill. It connects your computer CNC programming work to the real machine. It makes sure that the first cut happens in exactly the right spot.