Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

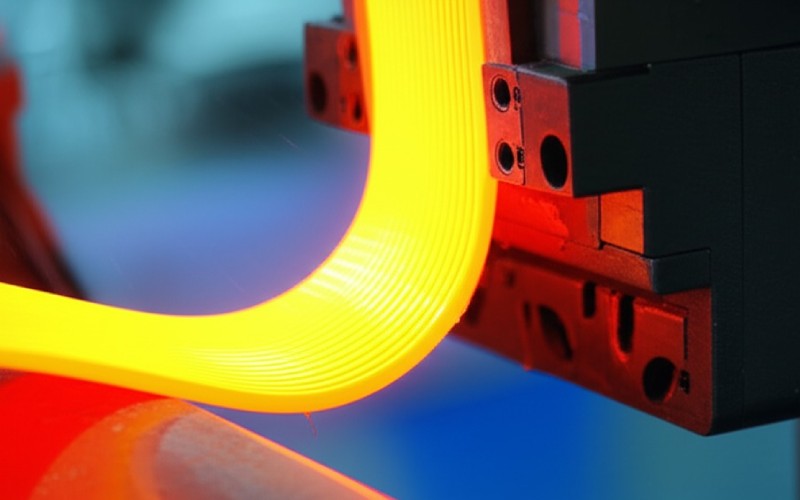

Plastic extrusion is a key part of modern plastic manufacturing, making a huge variety of plastic products we use every single day, from the pipes bringing us water to the thin films that keep our food fresh. In this article, I’ll take you on a tour of the world of plastic extrusion. We’ll look at how this clever process works, the different kinds of plastic extrusion, and the amazing variety of things it can make. If you’ve ever wondered how common plastic items are made, or if you work in manufacturing and want to understand more, this complete guide is for you.

To put it simply, plastic extrusion is a process where a raw plastic material, usually in the form of small pellets or beads, is melted down and shaped into one long, continuous piece. You can picture it like squeezing toothpaste out of a tube; the shape of the tube’s opening decides the shape of the toothpaste strip. In plastic extrusion, a tool called a die is the “opening” that gives the molten plastic its final form as it is pushed through. This continuous process makes extrusion a very fast and cheap way to make items that have the same shape from end to end. The extrusion process begins when the plastic material is put into the extruder.

This high-volume manufacturing process is very important for the production of plastic parts used in many industries. The extruded products can be anything from simple pipes and tubes to complex custom plastic shapes, window frames, and decorative pieces. The great thing about plastic extrusion is that it can create these shapes in long, non-stop lengths, which can then be cut to the right size. This continuous nature of plastic forming is a big plus compared to other methods like plastic injection molding, which makes parts one at a time. Basically, extrusion is a process that helps create a wide range of products efficiently.

The flexibility of plastic extrusion also means that many types of materials can be used. Many different plastics can be part of the process, each with different features to fit the final use. This allows makers to adjust the qualities of the final product, like how stiff it is, its color, and how well it stands up to chemicals or sunlight. The extrusion is a high-volume manufacturing method that is vital for today’s world, and the process involves melting and shaping the plastic.

Now, let’s get into the details of how plastic extrusion works. The main part of the plastic extrusion process is the extruder, which is a machine that heats and melts the plastic and then pushes it through a die. The extrusion process starts when plastic pellets are fed from a large funnel, called a hopper, into the barrel of the extruder. Inside the barrel, a rotating screw moves the plastic beads forward. The rubbing and squeezing from the screw’s movement, along with heat from heaters around the barrel, makes the plastic melt into a smooth, liquid form.

As the molten plastic travels down the barrel, it is mixed completely to make sure it has the same temperature and makeup everywhere. This is very important for the quality of the final product. At the end of the barrel, the molten plastic leaves the screw and is pushed through a breaker plate and a screen pack. The breaker plate is a strong metal disk with many holes that does two things: it holds the screen pack in place and helps change the spiral flow of the molten plastic from the screw to a straighter flow. The screen pack is a set of wire filters that removes any bits that haven’t melted or any contaminant from the molten plastic.

Last, the clean, molten plastic flows through the die. The die is a tool made just for this purpose that shapes the plastic into its final profile. As the molten plastic comes out of the die, it is soft and easy to shape. To make the shape hard, the profile is then cooled, usually by putting it in a water bath or by using air to cool it. The way it is cooled is watched closely to stop the final product from bending or changing shape. After it is cool, the long piece can be cut to the length that is needed. The process to extrude plastic is a great piece of engineering.

To really get plastic extrusion, it helps to know the main parts of a plastic extruder. The plastic’s trip starts at the hopper, which is a big, funnel-shaped bin that holds the raw plastic material. From the hopper, the material goes into the feed throat, the opening at the back of the barrel. The barrel is a strong, thick steel tube that holds the rotating screw. Along the barrel, there are different heating and cooling areas that let you control the temperature of the plastic very carefully as it melts.

The most important part of the extruder is the screw. The way the screw is designed is very important for how well the extrusion process works. It is usually split into three parts: the feed section, the compression section, and the metering section. The feed section just moves the solid plastic pellets forward. In the compression section, the screw channel gets shallower, which packs the plastic together, pushes out any trapped air, and creates heat from rubbing. In the metering section, the screw channel stays at a constant shallow depth, which makes sure the molten plastic is sent to the die at a steady speed and pressure.

At the end of the barrel, as we talked about, are the breaker plate and screen pack. These are very important for making sure the melted plastic is high-quality and well-mixed. Finally, there is the die, which is the tool that gives the plastic its final shape. Designing the die is a very skilled job, as it has to think about how the molten plastic flows and how its shape will change as it gets cool. These are the main components of a plastic extruder.

Plastic extrusion isn’t a single method that works for everything. There are a few different types of plastic extrusion processes, and each one is made to create certain kinds of products. The most common type of extrusion uses one screw, which is what we’ve mostly talked about so far. But there are also twin-screw extruders, which have two screws that fit together. These are often used for mixing things together or for working with materials that are harder to melt and move in a single-screw extruder.

Besides the kind of extruder, the extrusion process can be grouped by the type of product it makes. The main types of plastic extrusion processes are sheet (or film) extrusion, blown film extrusion, tubing extrusion, over-jacketing extrusion, and profile extrusion. Each of these methods uses a different kind of die and other machines after the die to make the shape and form that is wanted. For example, profile extrusion is used to make things with complicated cross-sections, like window frames, door seals, and plastic wood.

Knowing these different types helps you see the huge number of uses for plastic extrusion. The choice of which extrusion type to use is based on the final product that is needed, the type of plastic material being used, and how many you need to make. Each type of plastic extrusion has its own benefits for certain uses. This variety is what makes plastic extrusion such a necessary manufacturing process.

Sheet and film extrusion are two very similar kinds of plastic extrusion used to make flat sheets or thin films of plastic. The process is very similar to blow-film extrusion at the start. The plastic is melted in an extruder and then pushed through a flat die. The shape of the die’s opening decides how wide and thick the sheet or film will be. To make very wide sheets, a special die shaped like a ‘T’ or a coat hanger is used. This makes sure the molten plastic spreads out evenly.

After the molten plastic comes out of the die, the way sheets and films are made is a little different. For thicker plastic sheeting, the material is usually sent through a set of cooling rolls. These rolls not only cool the plastic but also help control its thickness and give it a smooth surface texture. This is sometimes called calendering. The sheets can then be cut to size or rolled up to be used later. This is a popular way to make plastic for things like packaging, signs, and building materials.

For thin plastic films, like the ones used for shopping bags or food wrap, a method called blown film extrusion is often used. In this method, the molten plastic is pushed through a round die. Air is then blown into the middle of the tube that comes out, which makes it bigger like a balloon. This stretching makes the film very thin and also helps line up the plastic’s molecules, which can make the film stronger. The bubble is then cooled by the air around it. At the top of the extrusion line, the bubble is flattened by nip rollers and wound onto a roll. The way to make sheet and film is very effective.

Just like it sounds, tubing extrusion and pipe extrusion are used to make hollow tubes and pipes. This is a very common use of plastic extrusion, making everything from tiny medical tubes to big pipes for water and gas. The process is like other kinds of extrusion, but the die is designed differently. A pin, also called a mandrel, is put in the middle of the die. This is what makes the hollow part of the pipe or tube.

The size and shape of the die opening and the pin decide the outside and inside size of the pipe or tubing. As the molten plastic flows through the die, it moves around the pin to make the tube shape. After exiting the die, the pipe or tubing is pulled through a tank of cool water. This helps make the plastic hard and keeps the size right. For some uses, a vacuum tank is used to make sure the outside of the pipe is perfectly round.

The wall thickness of the pipe is controlled by how fast the pipe is pulled from the die and how fast the extruder pushes out plastic. Pulling it faster will make the wall thinner, while pulling it slower will make a thicker wall. This fine control over the size is one reason why extrusion is ideal for making high-quality pipe and tubing. The pipe can then be cut to length or rolled onto a large spool.

Over-jacketing extrusion, also known as wire coating, is a special type of extrusion used for putting a protective plastic layer on the outside of something long, like a wire, cable, or even another plastic profile. This process is key for covering electrical wires to keep them safe and for giving fiber optic cables a strong, weather-proof jacket. The process works by pulling the main material through the center of a special extrusion die.

The die for over-jacketing extrusion is made so that the molten plastic flows around the main material as it goes through. There are two different types of tools for this process: pressure tooling and jacketing tooling. When pressure tooling is used, the molten plastic is pushed onto the main material with a lot of force, which makes it stick very well. This is often used when the jacket needs to be strongly attached to the core.

When jacketing tooling is used, the molten plastic makes a tube around the main material, and a vacuum is often used to pull the jacket tightly onto it. This way is often used when a looser fit is okay or wanted. After the coating is on, the product is then cooled, usually by passing it through a long container of water. This makes the plastic jacket hard and finishes the over-jacketing extrusion process.

A big benefit of plastic extrusion is that you can use many different kinds of extrusion materials. This lets makers create products with a huge range of features, from hard and strong to bendy and soft. The choice of plastic material is based completely on what the final product needs to do. Some of the most common plastics used in extrusion are polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS).

Polyethylene is a very useful plastic and is used to make many things, like films, bags, pipes, and tubes. Polypropylene is known for being resistant to chemicals and is often used for packaging, car parts, and fabrics. PVC is a very strong and weather-proof plastic, which makes it great for window frames, pipes, and house siding. Polystyrene is a hard and cheap plastic that is often used for throwaway cups, containers, and insulation.

Besides these common materials, there are many other special plastics that can be extruded, such as acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and nylon. These materials have better features like great strength, being hard to break, and working well at high temperatures. Being able to use these different types of plastics is a big reason why extrusion is widely used in so many industries. Picking the right type of plastic is a very important step when designing any extruded product.

The uses for plastic extrusion are very wide and can be found in almost every part of our daily lives. In the building industry, extrusion is used to make pipes for plumbing, window and door frames, siding, and deck boards. In the packaging world, plastic extrusion is used to make films for wrapping food, shopping bags, and shrink wrap. The car industry uses extruded plastic profiles for trim, seals, and tubes.

In the medical world, tubing extrusion is used to make many products, like catheters, IV tubes, and systems for giving medicine. The electronics industry depends on over-jacketing extrusion to cover wires and cables. Plastic extrusion is also used to make many things for shoppers, such as garden hoses, drinking straws, and office supplies. The list of applications for plastic extrusion goes on and on.

The reason for all these uses is how fast and flexible the extrusion process is. It lets you make complicated shapes in a non-stop way, and because you can use a wide variety of plastic materials, the features of the final product can be changed to fit the special needs of the use. From simple tubes to complex custom plastic shapes, plastic extrusion offers a way to solve a huge number of making challenges.

There are a few main reasons why plastic extrusion is such a popular and common manufacturing process. First of all, it’s a cheap process, especially when you need to make a lot of something. The continuous nature of plastic extrusion means it can work for a long time without stopping much, which means more products are made with less worker cost. The cost to make the first die tool can also be pretty low compared to other ways of making things, like plastic injection molding.

Second, plastic extrusion is a very flexible process. As we’ve talked about, it can be used to make many different shapes and profiles, from simple round tubes to complex shapes with many hollow parts. This freedom lets designers and engineers make new and useful plastic parts for many uses. The fact that you can use many different types of plastics makes it even more flexible.

Finally, extrusion produces items with a great outside finish and correct size. The carefully watched melting and cooling processes make sure the final product has the same features everywhere and a smooth, even look. This is important for many uses where looks and how well it works are very important. For all these reasons, extrusion is a high-volume manufacturing process that will stay a key part of the plastic fabrication industry for a long time. Using plastic extrusion has many benefits.