Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

I’ve been in the manufacturing world for a long time. If there’s one thing I’ve learned, it’s that the last part of a project is what makes it good or really great. You can have a perfectly designed part, but if the surface finish isn’t good, the whole product has problems. It’s an issue I’ve seen many times: a company spends a lot on design and CNC machining, but then has trouble with the last step. The parts look unfinished, they can get corrosion and wear out, and they don’t give customers what they expect. This isn’t just about looks; it affects how parts work and costs you money, which can hurt your brand name.

This is where a good surface finishing service is so important, and it’s why I’m writing this guide. Over the years, I’ve seen how the right finish can change a project. It can take a part from a simple prototype to a product ready for sale with great visual appeal. This article is your guide to understanding how important finishing services are. We’ll look at the many surface finishing options, explain the technical words, and help you make smart choices to improve your products. Whether you work with metal and plastic, this guide will give you the information you need to get that perfect final step.

Simply put, a surface finish is the process of changing the surface of a part to make it look a certain way or work better. This isn’t just about making something look nice, although aesthetic purposes are a big reason to add a finish. The real benefit, from my experience, is in how it helps the part work. A high-quality surface finish can improve corrosion resistance, make parts last longer (durability), and reduce rubbing.

Think about a part that has to be outside in the weather. Without a good protective coating, it will break down quickly. I’ve seen projects go wrong because this was forgotten. A simple powder coating or anodizing step could have stopped expensive replacements and protected the company’s reputation. The surface finish is usually the last step in the manufacturing process, but it is very important. It’s like a shield that protects your custom parts from the real world.

The issue for many engineers and designers is that they don’t think about the surface finish until the end. They focus so much on the main design and CNC machining that this last, key step is rushed or forgotten. This leads to problems like parts that don’t fit right because of a bad surface finish, or products that look old and worn after just a few months. The answer is to think about the surface finish from the very start of the design process.

Looking at all the surface finishing options can feel like too much. I’ve worked on projects where having too many choices made it hard to decide. The best way is to start by thinking about what you need. What is the main reason for the finish? Is it for functional or aesthetic purposes, or both?

If your main worry is corrosion resistance, you’ll look at choices like anodize for aluminum or plating for different metals. For parts that need to be very hard and resist wear, a Type III hardcoat anodize could be the right choice. But, if visual appeal is most important for your cosmetic parts, you could choose bead blasting for a nice matte look, or a high polish for a shiny, mirror-like surface.

The material of your part is also a very important thing to consider. A surface treatment that is great for a metal surface might not work at all for plastic parts. For example, vapor polishing is a great way to get a very clear, smooth finish on some plastics, but it doesn’t work on metals. The answer is to work with a surface finishing service that knows a lot about different materials and methods. I can’t count the times I’ve saved a project by suggesting a better, cheaper surface finishing option the client didn’t know about.

In my work with CNC machining, the “as-machined” surface finish is usually just the beginning. A CNC machine can make parts with a very exact tolerance, but the surface will always have marks from the cutting tools. For many uses, this standard finish is fine. But when you need to make more than just a prototype, other finishing services are needed.

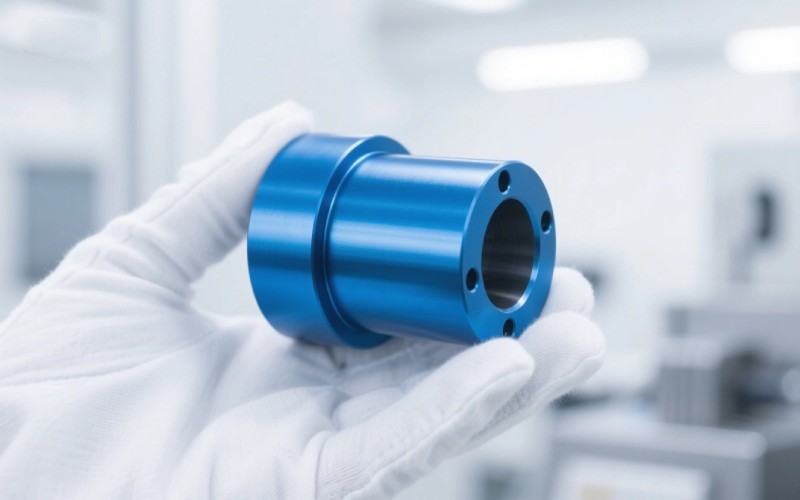

One of the most popular and useful finishes I suggest for aluminum CNC parts is anodizing. It’s an electrochemical process that gives great corrosion resistance and also makes a hard, strong surface. Also, because a Type II anodize is porous, it can be colored with a dye in many color options. This is a big plus for branding and aesthetics. You can even get specific colors using a Pantone or RAL color guide.

For both metal or plastic parts made by a CNC machine, bead blasting is another one of my top suggestions. This process uses a sandy abrasive media to make a smooth, even matte finish. It’s great for hiding small defects such as hang marks or a scratch from when the part was made and for cutting down glare. When a client needs a low-cost way to get a professional, high-quality look, bead blasting is often the answer. It’s a useful process that gives a steady surface finish on the whole part.

Yes, you can. While the bright color options of Type II anodizing are a big reason people choose it for aesthetic purposes, the benefits for how the part works are where this surface finishing process is really great. I’ve often had to explain to clients that anodize is not just a pretty coating. The problem is they see the color and don’t understand the big improvements to the mechanical properties.

Let’s think about that more. Picture an aluminum part that gets a lot of wear. Without a good finish, that part will get scratched, stuck, and break. Now, think of that same part with a Type III hardcoat anodize. This process makes a much thicker and stronger oxide layer, which gives it amazing surface hardness and wear resistance. In many of my projects, choosing a Type III anodize was the secret to making sure parts had long-term durability and worked well in tough places. It’s a solution that gives both corrosion resistance and amazing strength.

The difference between Type II and Type III anodize is in how the process is done. Type III is done at a lower temperature, which makes that harder, tougher coating. While Type II is good for cosmetic uses and general corrosion protection, Type III is the best choice for tough jobs. It’s a key surface finish I use for any project with aluminum custom parts.

Not many things look as good as a perfectly polished part. I’ve worked on consumer goods where the visual appeal of a high polish was the main reason people bought them. But getting that smooth finish takes several steps and a person with skill. You can’t just take a rough part from a machine and hope to get a mirror polish.

The process usually starts by taking off any sharp edges and getting the primary surface ready. This can mean sanding with finer and finer sandpaper to get rid of any scratch or defect. For a perfect surface finish, the part must be made very smooth before any polishing chemicals are used. This first step is very important; if you rush it, you will see the problems in the final part.

After the substrate is perfectly smooth, the polishing starts. This can be done by hand or with a buffing machine, using special polishing chemicals. The aim is to melt the surface just a tiny bit, which makes a very shiny and even finish. It takes a lot of work, but for parts where aesthetics are most important, there is nothing better than a high-quality polish. It provides that project that final step to perfection.

Even though there are newer methods, sand blasting, or what is now called abrasive blasting, is still a very useful and good surface finishing method. I’ve used it for many projects over the years. The problem is that the name “sand blasting” is a little old-fashioned. Because of health issues with silica sand, many other types of abrasive media are now used, like glass bead, aluminum oxide, or even crushed walnut shells.

The confusion comes from wrong ideas about the process. Some people think it’s a rough method that is only for big, heavy-duty jobs. But the truth is, by picking the right abrasive media and changing the pressure, you can get many different kinds of finishes, from a rough feel to a fine, matte look. The solution is to understand how flexible the process is.

For example, using a fine glass bead at a low pressure is a great way to clean and deburr fragile parts without changing their tolerance. On the other hand, a rougher media can be used to take off thick rust or to make a rough texture so a coating will stick better. It’s a very useful finishing service that, when used the right way, is a low-cost answer for preparing and finishing surfaces.

When you need a very clear and super smooth finish on plastic parts, vapor polishing is a wonderful choice. I remember the first time I saw how vapor polishing worked on a polycarbonate prototype; it was amazing. The part went from being a little cloudy and machined-looking to perfectly clear.

The problem with many plastic parts, especially from CNC machining or injection molding, is that they often have tiny flaws on the surface that make them look unclear. This can be a big issue for lenses or any product that needs to look very good. Polishing by hand or machine can sometimes add its own small scratches, which makes the problem worse.

The answer that vapor polishing gives is very smart and simple. The part is put in a special vapor that gently melts the surface of the plastic. This lets the plastic flow and smooth itself out, which gets rid of any roughness or flaws. The result is a glass-like surface finish that is very clear. It’s a very good surface treatment for materials like polycarbonate and acrylic.

After you have worked hard to make a part with the perfect surface finish, the last thing you want is a cheap-looking logo. This is where screen printing is useful. I’ve always said screen printing is the final touch that changes a product from a plain part to a finished, branded item.

The problem with stickers or other types of printing that don’t last long is that they can peel, fade, or scratch off. This makes the product look cheap and can hurt your brand name. It’s a small thing, but customers see it. Think of a well-designed machine where the brand name starts to peel off after a few months. It makes the whole product seem low-quality.

Screen printing is a strong and professional answer. The process uses a stencil on a fine mesh screen to push ink onto the part’s surface. The ink sticks strongly to the substrate, making a sharp, long-lasting image. It’s a great way to add logos, directions, or other important text right onto the flat surface of a part. Whether it’s a simple brand name or a detailed drawing, screen printing gives a high-quality cosmetic look.

This is a question that I think is central to good quality control in making things. Cosmetic acceptability criteria are the rules used to judge how a part looks. Without clear, agreed-upon rules, you will have arguments based on opinion. The problem starts when a client wants a “perfect” surface finish but doesn’t understand the limits of the manufacturing process.

The trouble is the constant arguing about what is an okay blemish or defect. Is a very small scratch on the b-side of a part a reason to send it back? What about minor defects on a surface that is not the main aesthetically important surface? These are the questions that can ruin a project and cause problems between people. I’ve seen this happen, and it’s almost always because the cosmetic acceptability criteria were not decided on at the start.

The solution is to agree on these rules before making the parts. This means saying what kind of aesthetic defects are not okay on the a-side (the main visual surface) compared to the b-side. For example, the a-side might need to be totally free of scratches, but the b-side can have some minor defects. Industry rules like SPI for plastics or VDI for textures can give you a starting point. A professional surface finishing service can help you set these rules, making sure you get parts that look the way you want and can guarantee defect-free production on the parts that matter most.

Over my career, I’ve seen companies try to do finishing services themselves to save money. Usually, it costs them more in the end. The problem is that getting a steady, high-quality surface finish needs special tools, clean rooms, and a lot of knowledge. It’s not something you can just learn as you go.

The problems come from getting different results each time, having to throw away many parts, and slowing down production. A machine shop is great at cutting metal; they are not always experts in the electrochemical process of anodizing or the skill of vapor polishing. Trying to do everything often means you are not great at anything. This can lead to a defect in the finish that ruins the whole part, like a bad powder coating or an uneven anodize.

The best choice is to work with a special surface finishing service. We have the expert knowledge and tools to offer many surface finishing options for both metal and plastic parts. We know the details of different materials and how to get the best surface finish for what you need, whether it’s for functional or aesthetic reasons. By using our skills, you can make your production smoother, improve your products, and in the end, sell a better product. We can even give you an instant quote to help you plan your project’s budget.