Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Picking between an AC motor and a DC motor might look hard. But it is very easy once you learn the basics. This article will be your guide. I will explain the world of AC and DC motors using simple words. We will look at how AC and DC power are different. When you finish reading, you will know how they work. You will also know where they are used. And you will know how to choose the right electric motor for what you need. It could be for a small project at home or for big jobs in factories (industrial applications).

Let’s begin with the first step. What is an electric motor? It is a machine. It turns electrical energy into motion. We call this motion mechanical energy. Think of a fan in your room. You put the plug in the wall. The electrical energy from the wall makes the fan blades spin. The spinning is the mechanical energy. The electric motor is the hero inside that fan making it all happen.

Electric motors play a very big part in our lives. They are in our houses, our cars, and in the factories that make the things we use. You can find them in the tiny motor that makes your phone shake. You can also find them in the huge motors that run factory equipment. These motors operate using a simple idea. They use electricity and magnets to make things move. The way they use that electricity splits them into two main groups. This is where the big AC vs DC talk starts.

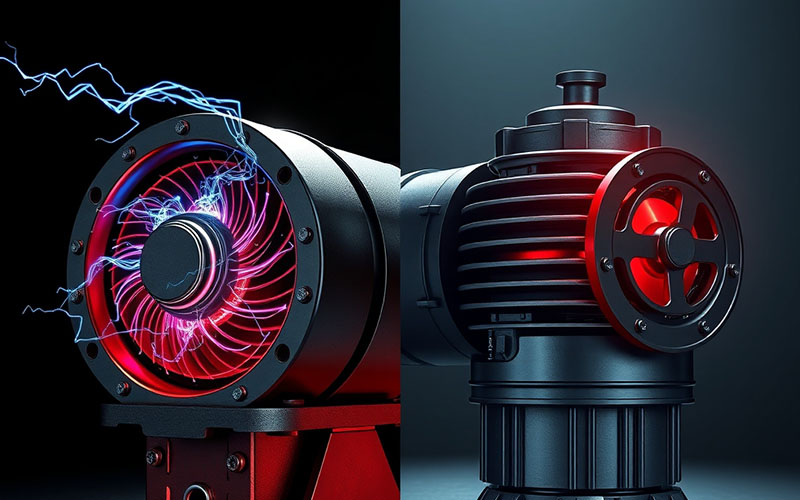

When you look at all the motors in the world, you will see many kinds. But almost all of them fit into two large families. These are the AC motor family and the DC motor family. The biggest difference is the kind of power source they need. The answer is right in their names. AC means Alternating Current. DC means Direct Current. The current supplied to the motor decides what type of electric motor it is.

Think of electricity as water moving in a pipe. Direct Current (DC) is like a smooth flow of water. It only moves in one direction. Batteries give you DC power. Alternating Current (AC) is like water that moves forward and then backward, very fast. The power you get from the plugs in your house is AC power. Knowing this basic difference between AC and DC is the first step. It helps you understand DC and AC motors. These basic (fundamental) differences between AC and DC currents decide how each motor type is made and what it is good for.

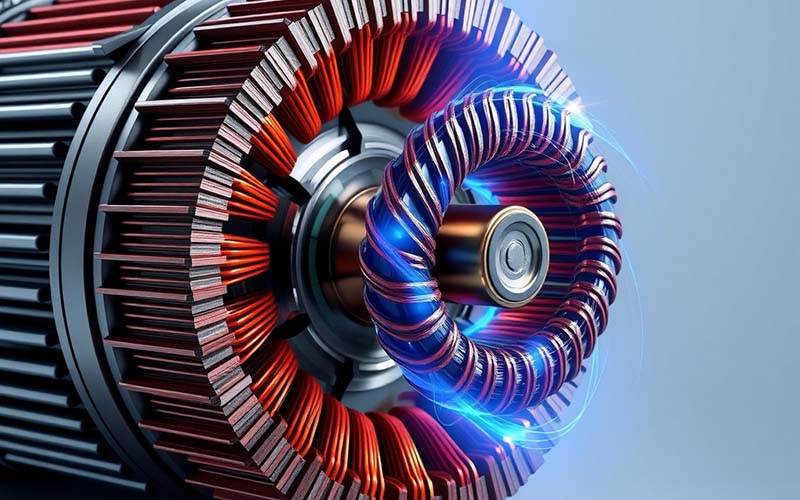

A DC motor is a good place to begin because it is a little easier to understand. It works with direct current. As I said, this current flows in just one direction. Inside a simple DC motor, you will find magnets. You will also find a part that spins called a rotor. When power goes into the DC motor, it makes a magnetic field around the rotor. This magnetic force pushes against the other magnets inside the motor. This push is what makes the rotor rotate, or spin.

To keep the rotor spinning, a simple DC motor uses two important parts. One is called a commutator and the other is a brush. The brush is a small part that touches the spinning commutator to send it power. The commutator is a special ring. Its job is to flip the magnetic field in the rotor. It does this every time the rotor spins halfway around. Because it keeps switching, the rotor is always pushing away from the magnets. This is what makes it keep spinning. The design is simple, which is why the DC motor was created first. The commutator and brushes work well, but the brush does get worn out after a while.

Now, let’s look at the AC motor. This type of motor works with alternating current. This is the power that you get from the plugs in your wall. An AC motor works in a way that is a little different. It usually does not need a brush or a commutator to work. This is a very good thing. The most common kind is the AC induction motor. These motors use a neat trick to make things move.

Inside an AC motor, the alternating current moves through the outside part of the motor. This makes a spinning magnetic field. You can picture it like a magnetic field that is always turning in a circle. This spinning magnetic field makes the rotor want to follow it. This pull causes the rotor to rotate. The speed of the AC motor is connected to the frequency of the AC power. In the U.S., this is 60 times every second. They do not have parts like a brush that rub on other parts. Because of this, AC motors are generally something you can count on and require less maintenance.

So, we know an AC motor and a DC motor use different kinds of power. But what else makes them different? A simple table can help us see things more easily. Knowing these basic (fundamental) differences is a big help when you are choosing a motor.

| Part to Compare | AC Motor | DC Motor |

|---|---|---|

| Power Source | It can be more complex. It often uses a brush and commutator (but some are brushless). | Direct Current (DC) from batteries or a special power supply. |

| How It’s Made | Usually simpler, with no brushes. Common kinds are induction motors and synchronous motors. | Speed is changed by changing the frequency of the AC current. This can be a bit tricky. |

| Speed Control | Brushed DC motors need more care because the brush has to be replaced. | Speed is easy to change by changing the input voltage. |

| Upkeep | Needs less care because there are no brushes to get old. | Brushed dc motors need more care because the brush has to be replaced. |

| Starting Torque | Usually has a lower starting torque. | DC motors offer great starting torque. This is a strong twisting force when it starts. |

This AC vs DC motors chart shows that one is not always better than the other. The choice of motor really comes down to the job it needs to do.

This is a very important question. If you need to change your motor’s speed easily and get it just right, a DC motor is often the best pick. Speed control in a DC motor is not hard at all. You just change the voltage. More voltage gives you more speed. Less voltage gives you less speed. This makes DC motors great for applications requiring precise speed changes. A DC motor also gives you great torque (that is the twisting force) even when it is spinning slowly. This high torque at low speeds is a really big plus.

Speed control for an AC motor is not as simple. AC motors run at a speed that is set by the frequency of the AC power. To change the speed, you need a special box called a variable frequency drive (VFD). This can make everything cost more. An AC motor has a lot of power. But, it can have trouble making high torque at very low speeds when you compare it to a DC motor. So, for work that needs great speed and torque control, DC motors are preferred.

When we talk about pure power, both AC and DC motors can be very strong. For jobs that need very high power, like in big industrial machinery, you will often see an AC motor. They are tough. They can also run for a long time without needing much attention. They can plug right into the main power lines, which is helpful for high power work.

But, the story is a little different when we talk about how well they use energy. This means how well a motor can convert electrical energy into mechanical energy without making a lot of waste heat. Brushed DC motors can waste some power because of the rubbing between the brush and the commutator. But brushless DC motors are very good at using energy well. In many situations, an AC motor can be less efficient than DC motors, especially the brushless kind. For things that use batteries, every little bit of power is important. So, a DC motor that uses energy well is usually the top choice.

I have talked about brushed DC motors and brushless DC motors a few times. Let’s take a quick look at how they are different. This is a key piece of information in the world of the DC motor. As we learned, a brushed DC motor uses a brush and a commutator. They work together to switch the magnetic field and keep the rotor spinning. They are simple to make and do not cost much, but the brush does get old.

Brushless DC motors are a bit smarter. They use computer parts instead of a brush to switch the magnetic field. This gives them big pluses. There is no brush to get old, so they work for a much longer time. They also need less care. They use power better and make less noise. The only downside is that brushless motors cost more. They also need smarter electronic parts to run them. You can find brushless DC motors in things like computer fans, drones, and new power tools where you need them to work every time.

You may not always see them, but motors are used all over the place. AC motors are used in a lot of household appliances. This is because they can be plugged right into a wall outlet. Think of your refrigerator, washing machines, and your air conditioner. AC motors are often the power behind these items. In big factories, you will see large AC motors making pumps, fans, and moving belts work. These industrial applications need the kind of power you can count on, and an AC motor gives them that.

DC motors are often used in things that get power from batteries. This includes your cordless drill, toy cars, and electric vehicles. DC motors find their place in applications that require changing speed control and strong starting torque. For example, electric wheelchairs use a DC motor. They need very fine control and the power to get moving up a hill. DC motors are used in your car for things like the power windows and the wipers on your windshield. You can be sure that motors are commonly used just about everywhere!

We have learned a lot. Now we get to the most important part. How do you choose the right AC or DC motor? Choosing a motor is about asking yourself a few key questions. When you answer them, you will know the right motor for your motor for your application.

Thinking about these power levels and what your project needs is how you make a good choice. Picking the right AC or DC motor is crucial. There are many motors available. But knowing the AC vs DC motor basics will help you find the one that is just right. Motors were developed to do work for us. Picking the right one changes everything.