Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Do you ever see that clear, colorful plastic and wonder what it is? It is probably acrylic! In this post, I will tell you all about this great material. We will learn what it is. We will see the different kinds you can get. We will also look at the fun ways to use it. You can make pretty paintings or strong signs. You will find out why acrylic can be a better pick than glass. You will also learn how to use it for the things you want to make. This guide is great for everyone. It is for artists. It is for people who like to make things at home. It is for anyone who wants to learn about this useful material.

I remember the first time I used an acrylic sheet. I was surprised. It looked a lot like glass. But it felt much lighter. Acrylic is a type of plastic. Its science name is polymethyl methacrylate, or PMMA for short. It is a synthetic polymer. That is just a science way of saying it is a material made by people. It is created through a chemical process.

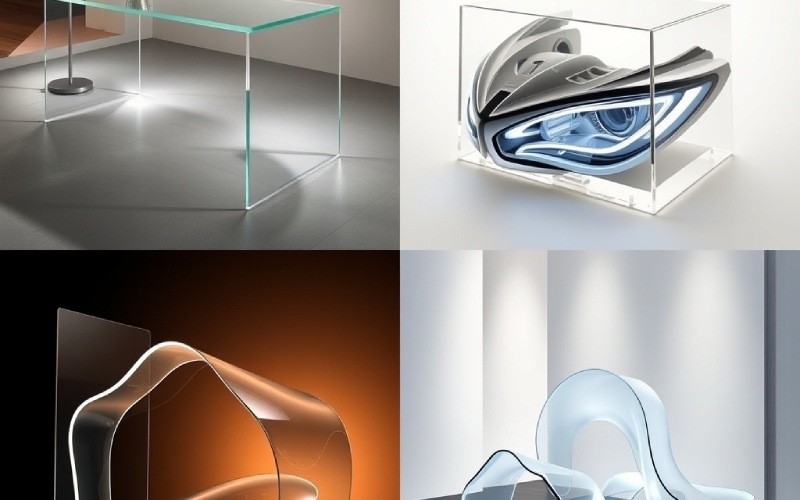

You can think of it as a clear, strong plastic. You can use it instead of glass for many things. This useful material has been here since the 1930s. It has become very well-liked, and there is a good reason for it. People know it is very clear, strong, and not heavy. You might also hear it called by brand names like Plexiglas or Lucite. But they are all types of acrylic. The way acrylic is made makes it easy to create in different shapes. It can be made into a solid sheet, a tube, a rod, or even a liquid form for paint. This ability to change is what makes it so helpful. You can use it for many fun and useful projects.

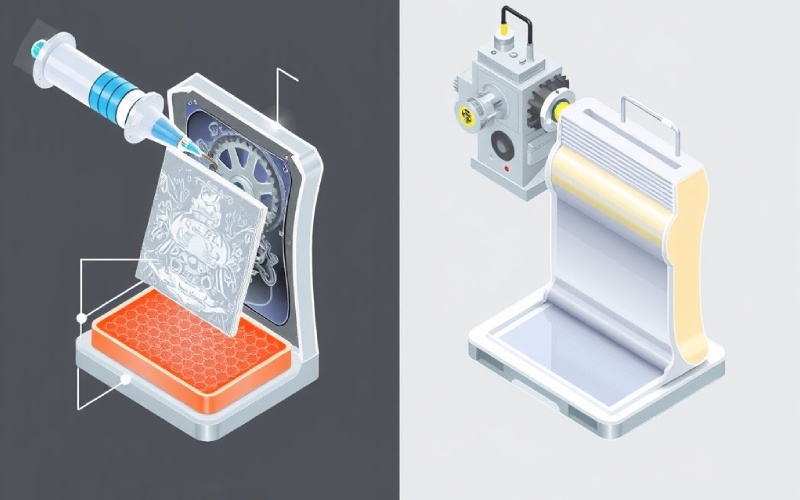

When I first started to learn about acrylic, I learned something fast. Not all acrylic is the same. There are different kinds. Each kind has its own special feature. The two main types of acrylic sheets you will find are cast and extruded. Cast acrylic is made a certain way. People pour liquid acrylic into a mold. This process makes it very strong and steady. Extruded acrylic is made by pushing the acrylic through a machine. This is a cheaper way to make it.

Besides these two main kinds of acrylic, you can find many special choices. For instance, you can find sheets with color and different feelings on the surface. These are for fun design projects. You can even find acrylic sheets that look like a mirror. They look just like a glass mirror. But they are much safer and not as heavy. Some sheets are made so they do not scratch easily. Other sheets are made to cut down on the shine from lights. You can even find sheets that block UV light from the sun. These protect things. There are also sheets that do not attract dust. When you know about these common kinds of acrylic, it will help you. You can choose the best one for what you need to do.

I have had to fix broken windows. I can tell you that using an acrylic sheet instead of glass is a good idea. The biggest difference is strength. An acrylic sheet is much harder to break than glass. It can actually be 10 times stronger and less likely to break. If it does break, it does not make a lot of small, sharp pieces. Glass does that. Instead, it breaks into bigger pieces. The edges are not as sharp. This makes it a much safer choice. It is very good for homes with children.

Another big difference is weight. Acrylic weighs about half as much as glass. This makes it much easier to hold. It is also easier to move and put in place. This is a very big help. It is good for projects you do yourself. It is also good for big jobs. Even though it is not heavy, acrylic is very strong. When you look at how clear it is, an acrylic sheet is just as clear as glass. It lets about 92% of light come through. Also, it holds up well in bad weather and sunlight. It will not turn yellow after a long time outside. Lastly, acrylic is often a cheaper choice than glass. This makes it a great pick for many projects.

| Feature | Acrylic Sheet | Glass |

|---|---|---|

| Strength | Hard to break, does not shatter | Easy to break, shatters |

| Weight | Not heavy (half the weight of glass) | Heavy |

| Clarity | Very clear, lets a lot of light through | Very clear |

| Safety | Breaks into big pieces that are not sharp | Breaks into many small, sharp pieces |

| UV Resistance | Very good, does not turn yellow | Good |

| Cost | Usually costs less | Can cost more |

After many years, I have learned to like the special features of acrylic. These features make it great to use. One of its main good points is that it is useful for many things. It is also easy to work with. You can heat it. Then you can shape it into almost any form you can think of. When it gets cool, it stays in that shape. Then you can cut it. You can drill holes in it. You can work on it with tools, just like you do with wood. This makes it perfect for making your own special designs.

Another key feature is that it is very strong. Acrylic holds up very well in bad weather. This means it can be in the sun, cold, and rain. It will not lose its color or get weak. This makes it a great material to use for signs or windows outside. It is also good at keeping heat in. It is better than glass at this. This can help you save money on heating. I also like that it is easy to take care of. You just need to clean it in a simple way with the right things. This keeps it looking new for a long time. It is strong. It is not heavy. And you can be creative with it. This mix of things is a big plus for many uses.

Because I like art, I have had a lot of fun trying acrylic paint. Just like acrylic sheets, there are different kinds of paint you can choose. The biggest difference you will see is how thick or thin they are. The three common types are heavy body, soft body, and fluid acrylics.

Heavy body acrylics feel thick, like butter. They are a lot like oil paint. They are very good for making different feelings on the surface. They also show the marks from your brush in your art. Soft body paints are not as thick. They are a good pick for small details. This is for when you want the paint to move more easily. Fluid acrylics are even more watery. They are great if you want to pour paint. They are also good for making light layers of color. Besides how thick the paint is, you will also find “student-grade” and “artist-grade” paints. Artist-grade paints have more of the stuff that gives paint its color. This means the color will be stronger and will last longer. Student-grade paints cost less money. They are a great pick for people who are just starting to learn about acrylic painting.

One of the best things I learned about acrylic painting is this. You can use it on many different kinds of surfaces. You do not have to use only paper or canvas. Acrylic paint is useful for many things. It will stick to almost any surface. The surface just can’t be too oily or glossy. This gives you many new ideas for being creative.

Here are some of the most liked surfaces for acrylic painting:

Using an acrylic sheet for the first time might seem hard. But I learned it is pretty easy if you have the right tools. You also need to be a little patient. The way you cut the sheet will be different. It changes based on how thick the sheet is. For sheets that are not very thick (up to 1/4 inch), the easiest way is to score and snap. You need a sharp utility knife and a ruler. You use them to make a deep line in the acrylic. After you make the line a few times, you can put the sheet on the edge of a table. Then you can snap it. It will break right on the line.

For sheets that are thicker, you will need a saw. You also need a saw for cutting curves. A jigsaw or a band saw is good for making curved shapes. A table saw or a circular saw is great for cutting in a straight line. The most important thing is the saw blade. You should use one that is made for cutting plastic. These blades have small teeth. They will not break or crack the material. It is also smart to cut slowly and at the same speed. This will stop the acrylic from getting too hot and melting. If you want to make bends or a special shape, you can use a heat gun. This will make the plastic soft. Then you can carefully bend it the way you want. You have to hold it that way until it gets cool.

When you start to look for it, you will see acrylic in many places. It has a special mix of features. This makes it helpful for a lot of common uses. In houses, people often use it instead of glass. It is a safe and strong choice for things like the tops of tables, shelves, and the walls behind kitchen counters. It is not heavy. And it is hard to shatter. So it is a perfect pick for these places.

You will also find acrylic used in many places of business. Shops use it to show items and to make signs. They use it because it is clear. It can also be easily made into special designs. Big public aquariums use thick sheets of acrylic for their windows. They use it because it is strong and clear. In art and design, people use acrylic for many things. They use it for picture frames. They also use it for new kinds of furniture. It is even used by doctors for tools. The army also uses it for things like the windows on airplanes. This is because it works well and is very strong. These are just some examples. They show how this useful material is used everywhere.

There are many choices. So how do you pick the right kind of acrylic for what you want to do? The first thing I think about is how I will use it. Will I use it inside or outside? If it is for outside, I will be sure to get a sheet that is safe from the sun. This will stop the sun from hurting it. Next, I think about how I want it to look. Do I need a sheet that is totally clear? Or would a sheet that is frosted, has a texture, or has a color be better for my design?

How thick the sheet is is also a very important choice. If you are making something that needs to be very strong, like a table, a thicker sheet is the better pick. For a basic picture frame, a thinner sheet is okay. Last, I think about how much money I can spend. Cast acrylic usually costs a little more money. But it is also stronger. It is also easier to work with using tools. This makes it a good pick for top-quality, special projects. Extruded acrylic costs less. It is a great choice for many everyday projects. If you think about these questions, you can feel good about your choice. You can pick the perfect acrylic for your great idea.

I have learned that if you take good care of your acrylic things, they will keep looking nice. This is very important. The main thing to remember is to be careful and not rough. When a surface needs to be cleaned, use a soft cloth. A microfiber cloth is good. Use it with gentle soap and water that is not too hot or cold. You should never use strong chemical cleaners. Do not use things like ammonia or acetone. They can hurt the surface. They can make it look cloudy or even cause cracks.

If your acrylic gets a scratch, do not worry! Small scratches can often be rubbed away. You can use a special polish for plastic. You can even use car wax. If the scratches are deep, you might need to do more. You can use sandpaper with very small grit and water. You do this before you polish it. Acrylic can sometimes get static electricity. This makes dust stick to it. You can fix this. You can use a special cleaner for plastics that stops static. You can also wipe it with a wet cloth. If you follow these easy steps, you can make sure your acrylic things stay pretty for a long, long time.