Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Glass-filled nylon is not your normal, everyday plastic. It is a special kind of nylon that has very small glass fibers mixed inside it. This mix makes the nylon a lot stronger. But is it the right choice for what you are making? This article will tell you all about it. We will look at all the advantages and disadvantages of glass-filled nylon. When you are done reading, you will know if this strong nylon material is what you need.

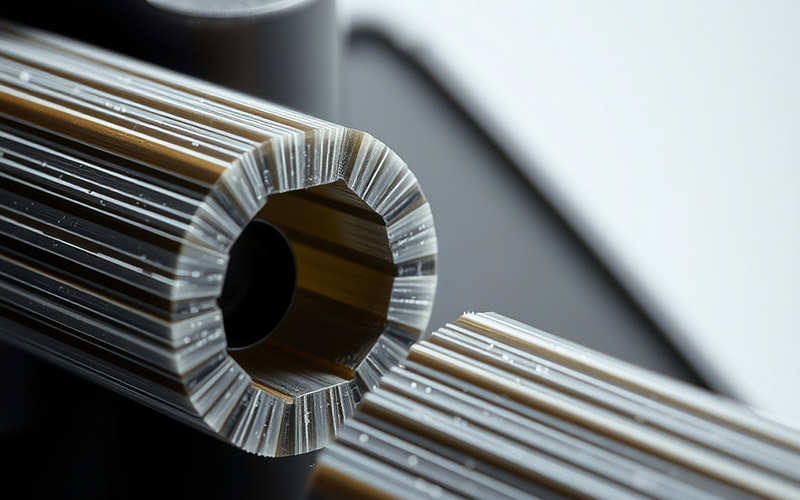

Let’s begin with the basics. You have probably heard of nylon. Nylon is a synthetic polyamide. It is a strong plastic that can also bend. People use it in everything from clothes to parts for cars. Now, think about taking that useful nylon and making it even stronger. That is what we do when we make glass-filled nylon. We take the main material, which is nylon, and we mix in very tiny pieces of glass fiber.

This is not like mixing big pieces of glass into plastic. The glass is usually like a powder, which is called powdered glass. Or, it can be in the form of tiny, thin strings of fiber. A good way to think about it is like putting steel bars inside of concrete to make it stronger. The nylon is like the concrete, and the glass fiber is like the steel. This makes a new material called glass-filled nylon. This simple mix of nylon and glass changes the nylon in some very big ways. This glass-filled nylon is a man-made material that is used a lot.

You may be asking yourself, “Why do all that extra work?” Plain nylon is already a pretty good material. The answer is simple. We want to make it better for certain kinds of jobs. The addition of glass fibers makes a huge difference for the nylon material. It takes the good parts of nylon, like its low price and how easy it is to work with, and gives it new strengths.

The biggest reason for adding glass fiber is to improve the mechanical properties of the nylon. Regular nylon can bend and stretch quite a bit. That can be useful for some things. But for parts that must be very stiff and strong, that bending is a problem. By mixing in glass fibers, which is called incorporating glass fibers, we make the nylon much stiffer and tougher. The addition of glass fibers enhances the way the basic nylon works. We will talk more about these ways later. The final glass-filled nylon is a big step up from simple nylon for hard jobs.

I have used glass-filled nylon for many different jobs. The good points are very easy to see. The advantages of glass-filled nylon make it a great choice for many builders. When you put it next to unfilled nylon, the difference is huge. Having the presence of glass fibers inside gives it a real power-up.

Here are some of the main benefits of using glass-filled nylon:

This mix of strength and rigidity along with heat resistance makes glass-filled nylon a very useful material. The glass-filled nylon offers a lot more than a standard nylon can.

So, how can adding a little glass fiber make such a big change? It is all about how the two materials help each other. The nylon part is called the nylon matrix. It acts like a glue that holds everything in place. The short glass fibers are mixed all through this nylon matrix. When something pushes or pulls on the glass-filled nylon parts, those small fibers start to do their job.

Every single tiny glass fiber is very strong on its own. The force gets shared across the millions of fibers that are inside the nylon. This means one spot does not have to take all the pressure. This is what gives the material its higher tensile strength. This is also what provides the strength of glass-filled nylon. The enhanced strength and rigidity come right from this teamwork between the nylon and the glass fiber. This makes the rigidity of nylon much better. The strength and performance of the nylon are made much better.

Yes, it really can. This is one of the top reasons I pick glass-filled nylon for some of my jobs. Standard nylon can begin to get soft when the temperature gets high. If you have a part that is close to a hot engine, that can be a very big problem. The part could bend out of shape or break. I have seen this happen with unfilled nylon.

When you add glass fiber to the nylon, you make its heat resistance better. The glass does not get soft from heat in the same way plastic does. The glass fibers are like a skeleton inside the nylon. They help it keep its proper shape even when it gets very hot. A part made of glass-filled nylon can work in much hotter places than the same part made from standard nylon. This strength and heat resistance make glass-filled nylon a popular material for parts that have to work in hard, hot places. The glass-filled nylon can withstand a lot of heat.

Now, it is not all good news. It is important to know the pros and cons of glass-filled materials. No material is perfect, and this includes glass-filled nylon. I have learned there are a few things you need to look out for. These are the main disadvantages of glass-filled nylon. It is important to know the cons of glass-filled nylon.

One large problem is that glass-filled nylon is more brittle than unfilled nylon. It is very strong, but it does not like to bend. Regular nylon can often bend a lot before it breaks. Glass-filled nylon tends to snap all of a sudden if you bend it too much. The same glass fiber that makes it so strong also makes it bend less.

Another problem is the abrasiveness of glass-filled nylon. Those hard glass fibers can wear down the tools and molds that are used to make the parts. The glass-filled material is like using fine sandpaper. This means that molds for injection molding must be made from very strong steel. This can make them cost more money. This nylon material is hard on tools. We have to be careful with glass-filled nylon’s abrasiveness. This wear is caused by glass pieces inside the nylon.

| Feature | Standard Nylon | Glass-Filled Nylon |

|---|---|---|

| How Much It Bends | Bends a lot | Does not bend much (more brittle) |

| Strength | Good | Very Good |

| Tool Wear | Low | High (wears tools down) |

| How It Looks | Smooth | Can be less smooth, fibers might show |

| Weight | Lighter | Heavier |

| Cost | Cheaper | Costs More |

Working with glass-filled nylon can be a bit hard. It is very hard because of the glass fiber inside it. This can be tough on your tools. If you have to drill holes, cut it, or shape a finished part, you must be very careful. This work is called machining glass-filled nylon. Normal tools can become dull very fast.

It is recommended for machining glass-filled parts to use special tools. These tools should be made of super-hard materials like carbide. These tools are strong enough to handle how the glass fiber wears things down. You also need to be safe and not breathe in the dust. The dust from glass-filled nylon has very small glass bits in it. Your safety is always the most important thing. So, it is a great material, but you need the right tools and knowledge to work with it after a part has been made. This makes working with this type of nylon a little more difficult.

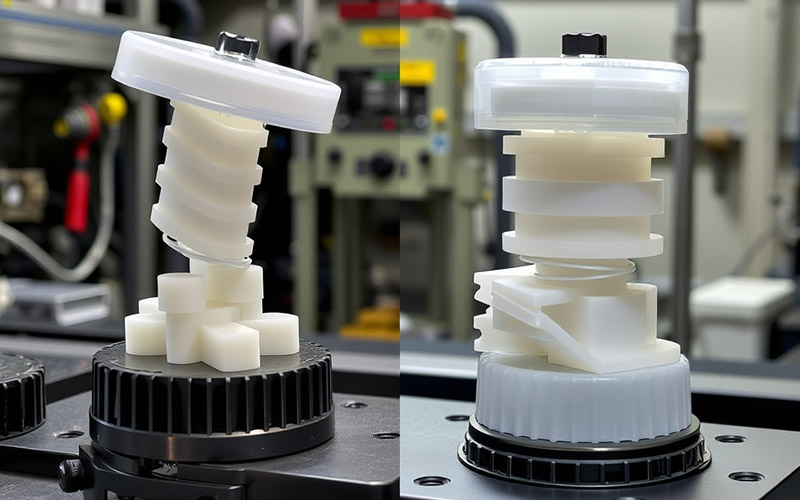

From what I have seen using plastic injection molding, working with glass-filled nylon changes some things. Like I said earlier, the material wears things down. The melted nylon resin, which is full of glass fiber, moves through a steel mold. After a while, it will start to wear out the mold. You must have a plan for this. We use special hard steel to make molds that will be used for a lot of glass-filled nylon.

The injection molding work itself has to be set up in just the right way. The way the melted glass-filled nylon flows is not the same as regular nylon. The glass fibers can all point in the same direction as the plastic flows. This can make the part very strong in one direction but weaker in another direction. A smart part designer knows this. They will design the mold to help control how the plastic flows. To get great glass-filled nylon parts from injection molding, you need a lot of skill and practice. The plastic injection must be done perfectly for this strong nylon. The injection molding process is very important.

You can find glass-filled nylon in many different places. You will often see it where parts need to be strong and handle heat. The ability of nylon to be used in many ways gets a big boost from the addition of glass. It is a very popular choice in the car industry. Many parts under the car’s hood are used in automotive work. Think about parts like engine covers, air intake parts, and cooling fan blades. These parts must be strong and light. They also have to handle the heat from the engine. Glass-filled nylon is the perfect material for this.

The use of glass-filled nylon is also very common for power tools, parts for home machines, and factory equipment. If you own a power drill, its tough outer case might be glass-filled nylon. It is also used to make gears, bearings, and support parts that used to be made from metal. Because it can be shaped with injection molding, you can make parts with tricky shapes. Making these shapes from metal would cost a lot of money. This is why glass-filled nylon is widely used. Many kinds of businesses uses nylon like this.

This is the last big question. To find the answer, you have to look at what you are making. Do you need more strength and stiffness than what regular nylon can give you? Does your part need to have good dimensional stability and not change its shape? Will it be used in a place that gets very hot? If you answered “yes” to these questions, then glass-filled nylon is a very good choice. You can get it in different kinds, like nylon 6 or nylon 66. A popular kind is glass-filled nylon 66.

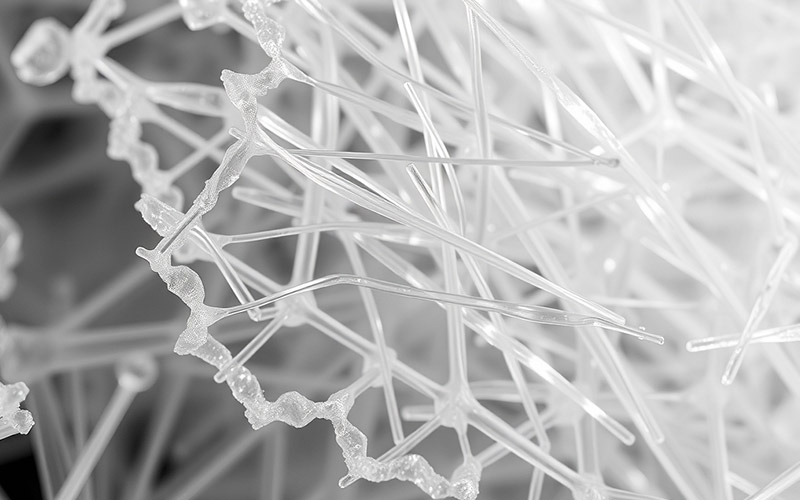

The amount of glass fiber inside can also be different. You can get glass-filled nylon with different amounts of glass fiber mixed in, anywhere from 10% to 50% or even more. The proportion of glass changes the way the glass-filled nylon acts. More glass means it is stronger, but it also makes it easier to snap. You have to find the right mix of nylon and glass for what you need. How much glass you add, which is the incorporation of glass, is a choice you make based on the nylon grade. It is a choice between using regular nylon and this stronger nylon.

I have given you a lot of information. Here is a quick list of the most important things to keep in mind about glass-filled nylon.