Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

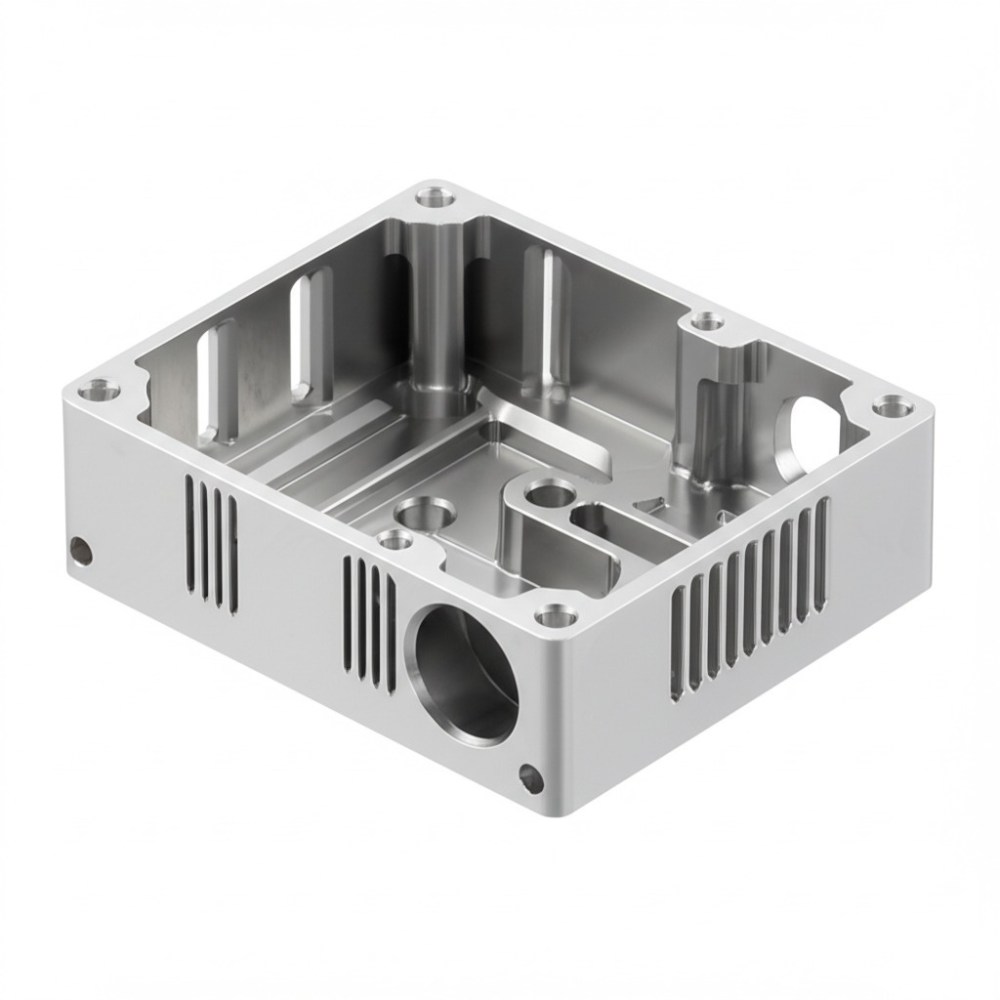

Aerospace CNC machining is a special way to make parts for airplanes and spacecraft. These parts must be perfect because lives depend on them. At Istar Machining, we use computer-controlled machines to cut and shape metals and other materials into parts that fly high in the sky or even into space!

Our precision CNC machining services help build the parts that keep planes safe and rockets soaring. From tiny screws to big engine parts, we make them all with amazing accuracy.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

When making parts for planes and spaceships, we can’t make mistakes. Here’s why:

That’s why we use the best 5-axis machining tools that can make complex shapes with perfect accuracy.

We use different machines and methods to make aerospace parts. Here’s what we do:

Machine Type | What It Does | Best For |

5-Axis CNC Machines | Cuts material from 5 different angles with ±0.0001″ accuracy | Jet engine blades, complex curved parts |

Swiss Machining | Makes very small parts between 0.5mm-32mm | Hydraulic fittings, tiny precision parts |

Wire EDM | Uses electrical wire to cut metal with no heat damage | Lightweight brackets, heat-resistant parts |

CNC Turning & Milling | Shapes parts up to 60″ long | Wing supports, big structural parts |

Industry 4.0 Smart Machines | Uses computers to check quality while making parts | All parts, reduces mistakes by 35% |

Our titanium CNC machining is perfect for aerospace parts that need to be strong but light.

Below is our complete guide to the materials we use in our 5-axis machining and other CNC services for aerospace parts:

Aluminum is the most common material we use at Istar Machining for aerospace parts. It’s light but strong.

Why Choose Aluminum:

Our team can make airplane wing ribs, brackets, valve bodies, and fuselage parts from aluminum with very tight sizes (±0.001″).

When parts need to be super strong but still light, we turn to titanium. This amazing metal is as strong as steel but 45% lighter!

Titanium Benefits:

At Istar Machining, we use special tools and methods like cryogenic machining to cut titanium for landing gear, engine mounts, and fasteners.

Some airplane parts get very, very hot. That’s where Inconel® comes in. This special metal can handle temperatures over 1,300°C!

Why We Use Inconel®:

Making parts from Inconel® is tricky, but our titanium CNC machining experts have mastered the methods needed to shape this tough material.

Stainless steel is the workhorse of aerospace materials. It fights rust, stays strong, and can be made into many shapes.

Stainless Steel Uses:

We use grades like 15-5 PH and 17-4 PH that meet the strict rules for airplane parts.

Not all airplane parts are metal! We also work with advanced composites like:

These materials are perfect for:

Material | Strength | Heat Resistance | Best Uses | Key Facts |

6061-T6 Aluminum | 310 MPa | Up to 175°C | Wing ribs, brackets | Light, fights corrosion, easy to machine |

7075-T6 Aluminum | 570 MPa | Up to 150°C | Structural frames | Strongest aluminum we use |

Ti-6Al-4V Titanium | 900 MPa | Up to 430°C | Landing gear, engine mounts | 5x stronger than steel but lighter |

Inconel® 718 | 1,400 MPa | Up to 1,300°C | Engine parts, rocket nozzles | Works in extreme heat |

15-5 PH Stainless Steel | 1,070 MPa | Up to 600°C | Hydraulic systems | Fights rust, very strong |

PEEK Composite | 100 MPa | Up to 250°C | Electrical parts | Non-metal, doesn’t conduct electricity |

Carbon Fiber (CFRP) | 5x steel strength | Up to 400°C | Satellite panels, drone parts | Ultra-light and stiff |

Our aerospace CNC milling services help make parts for many different uses:

When lives depend on your work, you need to be extra careful. Here’s how we check our work:

When you work with us, here’s what happens:

Our Swiss machining services are perfect for the smallest aerospace parts with the tightest tolerances.

There are many reasons top aerospace companies trust us:

We've made thousands of aerospace parts

Our machines are the latest and best

We know exactly how to work with special aerospace metals

We meet or exceed all aerospace standards

We understand that delays can be very costly

Excellence doesn't have to break your budget

Ready to make your aerospace parts a reality? Here’s how to begin:

Don’t trust your critical aerospace components to just anyone. Work with the experts at Istar Machining, where precision isn’t just a goal—it’s our promise.

Contact us today to discuss your aerospace CNC machining needs!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or