Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

In this post, you’ll uncover what a metal alloy is, just how it’s made, and why it’s so crucial in our daily lives. We’ll discover the various sorts of alloys and their unique properties, and I’ll even share some fun realities about one of the most typical alloys we make use of everyday. So, if you have actually ever before wondered concerning the materials that shape our world, you’re in the best area!

A metal alloy is a material made by combining 2 or even more elements, with at the very least among them being a metal. Think of it like a recipe, however as opposed to flour and sugar, you’re using various metals and in some cases also non-metals. The primary metal is called the base metal. When these aspects are blended, they create a new product with various buildings than the initial components. This brand-new product is the alloy. For instance, steel is an alloy of iron and carbon.

The remarkable point about an alloy is that it can be created to have details features. By changing the “dish” or the composition of alloys, we can make materials that are more powerful, lighter, or extra immune to corrosion. This is why alloys are so unbelievably valuable and located in virtually every little thing we make use of, from the coins in our pocket to the planes overhead. The term alloy is used to explain these amazing materials that are around us. A lot of the alloys we make use of today are the result of mindful experimentation to create products with preferable residential properties. The development of an alloy is an interesting procedure that has formed our world in many means.

A pure metal is made up of just one kind of atom. Think of a bar of pure gold; it consists of only gold atoms. Since all the atoms are the same size and arranged in a neat, organized means, they can move past each various other conveniently. This is why numerous pure steels are soft and can be conveniently curved or designed. While pure metals have their uses, they are commonly not strong sufficient for several work.

On the other hand, an alloy is a mix of various aspects, so it includes atoms of different sizes. This jumbles up the cool, organized setup of atoms discovered in a pure metal. It’s like trying to pack a box with both big and little balls; they do not meshed as neatly as a box of all the same-sized rounds. This irregular structure makes it harder for the atoms in the alloy to move past each other. As a result, alloys are usually harder and stronger than pure steels. As an example, steel, an alloy of iron and carbon, is a lot stronger than pure iron.

You could be stunned to learn how many usual alloy products you encounter daily. From the moment you awaken, you are surrounded by different alloys. The stainless steel in your cooking area sink and cutlery is an alloy of iron, chromium, and occasionally nickel. Your house keys are likely made from brass, an alloy of copper and zinc. Also the coins in your budget are constructed from different copper alloys.

Below’s a table showing some typical alloys and their day-to-day usages:

| Alloy | Composition | Usual Makes use of |

|---|---|---|

| Stainless Steel | Iron, Chromium, Nickel | Cooking area utensils, medical tools |

| Brass | Copper, Zinc | Musical tools, plumbing installations |

| Bronze | Copper, Tin | Sculptures, medals, bells |

| Carbon Steel | Iron, Carbon | Tools, cars and truck parts, buildings |

| Light weight aluminum Alloy | Aluminum, Copper, and so on. | Aircraft, autos, cans |

These are just a few examples of the several alloys that play a vital duty in our lives. Using alloys is widespread because they supply a series of preferable buildings that pure steels alone can not give.

Creating an alloy is a bit like baking a cake. You have to blend the right components in the right amounts and afterwards heat them up. The most usual method alloys are made is by melting the base metal and then adding the various other components, which are called alloying components. Once whatever is melted and mixed with each other, the liquid alloy is put into mold and mildews to cool and solidify. This process creates a strong product with a new set of physical properties.

An additional method to make an alloy is through a procedure called powder metallurgy. In this approach, the various elements are turned into great powders, mixed together, and afterwards pushed and heated at high temperatures up until they fuse. Despite which technique is made use of, the objective is to develop a brand-new product with boosted qualities. The procedure of alloying a metal is a vital step in creating the lots of different kinds of alloys we make use of today.

The structure of alloys refers to the specific aspects and their amounts that make up the alloy. This “recipe” is what gives each alloy its special properties. For instance, steel is an alloy of iron and carbon. A small amount of carbon, generally much less than 2%, is contributed to iron to develop a much stronger product. By changing the quantity of carbon, we can create various kinds of carbon steel with different degrees of firmness and toughness.

Here are some popular alloys and their structures:

The chemical structure of an alloy is meticulously managed to generate the desired physical and mechanical properties.

Alloys are so helpful due to the fact that they have a variety of various homes. By combining various components, we can develop an alloy with simply the right attributes for a specific task. As an example, some alloys are extremely strong, while others are extremely light. Some are resistant to heat, while others are superb at performing electrical power.

Right here are several of the vital buildings of alloys:

These mechanical properties and physical properties are what make alloys so flexible and crucial in a lot of various industries. The certain buildings of alloys are determined by their composition and how they are made.

Carbon steel is an extremely typical and commonly used alloy. As its name recommends, it is an alloy of iron and carbon. Actually, carbon steel make up about 90% of all steel manufacturing. The reason for its appeal is that it is fairly cost-effective to make and has a wide variety of beneficial residential or commercial properties.

The amount of carbon in the steel determines its homes.

The residential properties of steel, specifically carbon steel, can be further transformed by warm therapy. This makes carbon steel an exceptionally functional alloy that is used in a huge number of applications.

There are plenty of alloys in the world, each with its own unique uses. Allow’s have a look at some even more preferred alloys and what they are utilized for.

Right here is a fast reference table of some popular alloys and their primary usages:

| Alloy | Secret Quality | Main Makes use of |

|---|---|---|

| Titanium Alloys | Strong, light-weight, corrosion-resistant | Aerospace, clinical implants |

| Nickel Alloys | Warmth and corrosion-resistant | Jet engines, chemical plants |

| Gold and Silver Alloys | Resilient, eye-catching look | Precious jewelry |

| Brass Alloys | Corrosion-resistant, helpful for acoustics | Musical instruments, plumbing |

| Bronze Alloy | Tough, withstands exhaustion | Statues, bearings |

As you can see, alloys are made use of to develop a vast selection of items that we depend on each day.

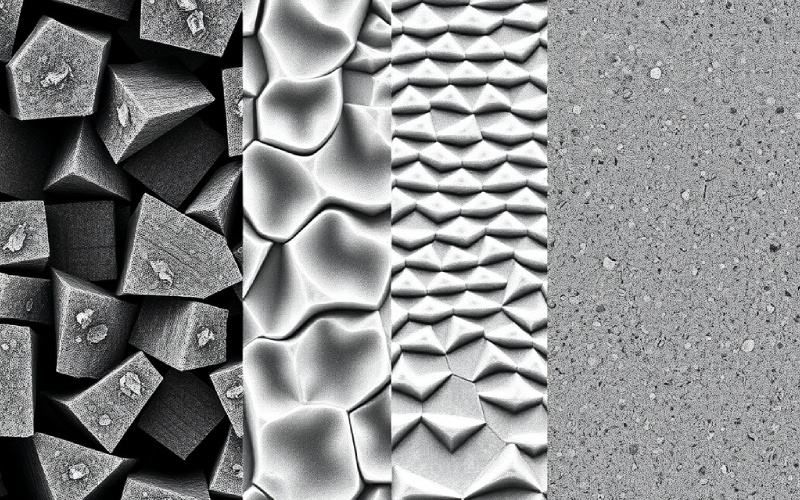

When we talk about exactly how alloys are formed at the atomic level, there are 2 primary types: interstitial and substitutional alloys. The difference between them relates to the size of the atoms of the alloying element contrasted to the atoms of the base metal.

A substitutional alloy is created when the atoms of the alloying element are about the same size as the atoms of the base metal. In this instance, the atoms of the alloying element can take the place of, or substitute for, several of the atoms of the base metal in its crystal structure. A good example of a substitutional alloy is brass, where zinc atoms replace a few of the copper atoms. Bronze, an alloy of copper and tin, is an additional instance of a substitutional alloy. Many common alloys are substitutional alloys.

An interstitial alloy is formed when the atoms of the alloying element are a lot smaller than the atoms of the base metal. These smaller sized atoms don’t change the base metal atoms. Instead, they fit into the tiny spaces, or interstices, between the base metal atoms. Steel is a timeless instance of an interstitial alloy. The little carbon atoms match the rooms in between the larger iron atoms. This makes the framework extra inflexible and boosts the tensile strength of the metal. Both interstitial and substitutional alloys lead to a product that is usually more difficult than the pure metal.

Alloys play a big function in our modern globe, and it’s tough to imagine life without them. From the structures we stay in to the autos we drive and the phones we make use of, alloys are all over. The reason they are so vital is that they allow us to develop materials with certain properties that are needed for a certain work.

A pure metal may be as well soft, too hefty, or could rust also quickly for a certain application. By developing an alloy, we can conquer these restrictions. We can make a metal that is both solid and light-weight, like the aluminum alloys made use of in aircrafts. We can create an alloy that is immune to corrosion, like the stainless steel used in our kitchens. And we can make an alloy that is extremely tough and sturdy, like the carbon steel utilized to make devices.

The development of brand-new alloys has actually been a driving pressure behind technical development throughout history. The first alloys, like bronze, transformed the program of people. Today, researchers and designers are continuously functioning to create brand-new alloys with even better homes to meet the needs of the future. The proceeded use alloys will certainly result in a lot more amazing innovations.