Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

If you care more about appearance, corrosion margin and extrusion-friendly shapes, 6063-T52 usually wins. If you care more about structural strength and machining, 6061-T6 usually wins. The real work is knowing when those rules quietly break.

Engineers often talk as if 6061-T6 is the “serious” alloy and 6063-T52 is the “architectural” one. That’s only half true. Both are 6000-series Al-Mg-Si alloys with very similar chemistry, modulus and basic behavior.

What actually separates them in day-to-day design is narrower: strength level, surface quality, ease of extrusion, and how predictable the finish is after anodizing or coating. 6061-T6 brings higher yield and fatigue strength; 6063-T52 brings smoother extrusions and usually a small but real bump in corrosion resistance and thermal conductivity.

If you reduce the decision to a single question, it’s often this: “Am I strength-limited or finish-limited?”

You already know what “T6” and “T52” mean in the standards sense, so we can skip that. Let’s focus on the numbers and the bits the datasheets don’t spell out in plain language.

Chemically, 6061 tends to carry more copper and chromium, sometimes a little more silicon and iron than 6063. That extra alloying is part of why 6061 can be pushed to higher strength, and also why its bare corrosion resistance and anodizing consistency are slightly less forgiving than 6063 in many finishing lines.

Mechanically, in the tempers we care about here, the gap is not subtle. Typical catalog values for extrusions are roughly:

| Property (typical) | 6063-T52 | 6061-T6 |

|---|---|---|

| 0.2% Yield strength | ≈ 145 MPa (21 ksi) | ≈ 270 MPa (39 ksi) |

| Ultimate tensile strength | ≈ 185–200 MPa (27–29 ksi) | ≈ 300–310 MPa (43–45 ksi) |

| Elongation (gage length ~50 mm) | ≈ 10–12% | ≈ 10–12% |

| Modulus of elasticity | ~69 GPa (same family) | ~69 GPa |

| Thermal conductivity (room temp) | ~200–215 W/m·K | ~150–200 W/m·K |

| Relative corrosion resistance (bare) | Very good | Very good, usually slightly lower |

| As-extruded surface | Fine, smooth, “architectural” | Rougher, more machining marks |

| Typical cost at equal shape | Slightly lower | Slightly higher |

Values are representative for common extrusion sizes; exact numbers vary by mill, standard and section thickness.

Stiffness is basically the same. Both are aluminum with virtually identical modulus, so swapping 6063-T52 for 6061-T6 does not fix deflection problems; it mostly buys you stress margin.

Thermally, 6063 runs a bit higher on conductivity and specific heat, helped by the lower copper content. That matters for heat sinks, LED housings, or anything that lives its life as a radiator rather than a beam.

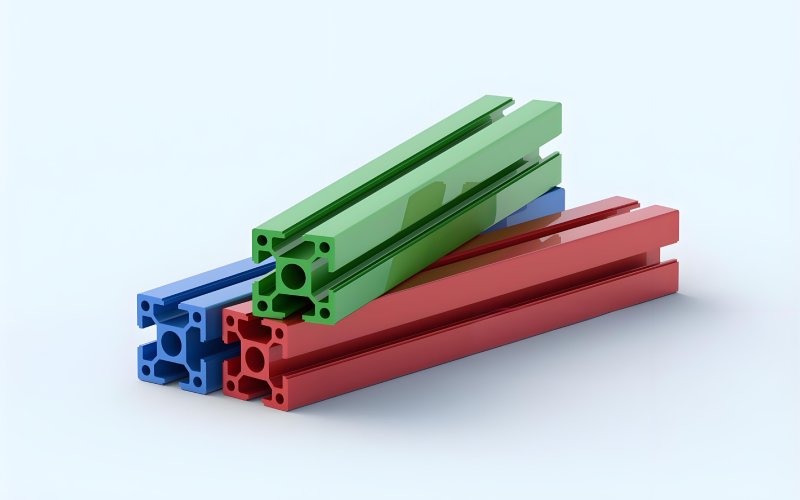

If the profile is going to be stared at, lit, photographed, or value-engineered by committee, 6063-T52 is usually the safer default. It extrudes with smoother surfaces, handles thin sections and complex shapes more kindly, and is the alloy many anodizers quietly prefer when you ask them about consistent color.

For curtain walls, window and door frames, sign structures, trims and rails that people touch every day, 6063 exists to make your life simpler. It accepts clear or colored anodizing with less prep, tends to show fewer extrusion lines, and its slightly better corrosion behavior is nice insurance for long-term outdoor exposure.

The catch is obvious: strength. You do not get T6-level numbers out of a T52 profile. If the wind loads, live loads or impact cases are genuinely high, either thickness grows or you move toward 6061-T6 (or 6082) for at least the load-bearing members.

Machining behavior for both alloys is “fine” by steel standards. That said, 6061-T6 usually cuts cleaner, holds threads better, and is easier to source in plate, bar and precision extrusions for CNC work.

If your part starts life as plate or block, 6061-T6 is almost always the natural choice. Fixture plates, brackets, housings, small machine parts, even consumer hardware where weight and stiffness matter: you get more strength and almost no downside unless the part is highly cosmetic and left as-machined.

When 6063-T52 sneaks in for machined parts, it’s usually because you are cutting features into an extrusion that was primarily chosen for shape and appearance. In that situation, you live with the fair-to-good machinability because the extrusion geometry was the real driver.

On paper, 6061-T6 gives you a big strength advantage. Once you weld it, that advantage shrinks, sometimes more than people expect. The heat-affected zone near the weld loses temper and drops toward a T4/O-like condition unless you re-heat-treat.

You still often pick 6061 for welded trusses, vehicle frames, marine structures and equipment skids because:

You can get heavier wall sections and structural shapes more readily in 6061, and its pre-weld properties let you carry more load away from the joints.

But when the frame is also the visible product — say a display system or architectural feature — the conversation changes. 6063-T52 can be attractive because its “architectural” surface makes post-weld finishing and anodizing less painful, and its bare corrosion resistance is at least as good, often noted as somewhat better when copper levels are low.

The subtle point: if your design is weld-strength-controlled right at the joints, the gain from 6061-T6 can be smaller than the datasheet suggests, because you’re no longer operating at that full T6 temper in the critical region. That’s where joint design and weld procedures matter more than whether the parent metal was originally 6061 or 6063.

For heat sinks, LED housings, power electronics enclosures and similar parts, the logic often flips. You are rarely stress-limited; you are dealing with thermal resistance, extrusion feasibility and surface treatments.

6063’s higher thermal conductivity and smoother as-extruded surfaces help here. Fins can be thinner and more closely spaced without tearing at the die as easily, and anodized matte black finishes tend to be predictable and repeatable. Designers in lighting and electronics often default to 6063 for exactly these reasons, unless the same part also has to be a structural member in a harsh mechanical environment.

6061 can still be used for thermal parts, of course, especially when the same extrusions are also carrying real loads. You just accept a slight thermal penalty in exchange for the higher strength.

Datasheets talk about corrosion and anodizing in a very generic way. The production reality is sharper. Many finishing shops will tell you some version of “use 6063 for extrusions if you care about color match; avoid mixing it with 6061 where surfaces line up.”

Because 6061 and 6063 differ slightly in composition, especially copper content, they can anodize to different tones under identical process conditions. Finishing suppliers explicitly warn that mixed alloys or mixed tempers will not produce fully uniform color, and recommend 6063 for extrusions where appearance and matching are critical.

So if you are designing a facade or product where several profiles align in one visual field, you should treat “same alloy and temper across visible parts” as a hard requirement, not an afterthought. Otherwise you risk a patchwork of slightly different grays or bronzes that only show up at installation.

This single issue — color match — is a strong, non-technical reason many teams standardize on 6063 for visible systems and reserve 6061 for hidden structural members and machined hardware.

The usual internet tables don’t talk much about edge behavior: very thin walls, very thick sections, tight tolerance schemes and forming after machining. Those are the places where a “stronger vs smoother” story is incomplete.

For very thin, complex extrusions, 6063 is often the only practical choice. Its extrudability lets die designers push wall thickness down and complexity up without constant headaches. If you try to force those same geometries in 6061, you may face higher rejection rates or design compromises (thicker walls, fewer details, slower extrusion speeds).

For very thick or heavy sections, 6061 starts to look better again. Stock availability is usually better for structural shapes, and the higher mechanical properties mean you can control weight by optimizing section, not just choosing an alloy and hoping.

On bending and forming, the story is “temper first, alloy second.” 6061-T6 is quite limited in tight forming; you typically move to T4/O for serious bends and then re-age. 6063-T52, being softer and stress-relieved, is more forgiving in many light-forming operations in its delivered state, especially for profiles like railings and trims that get rolled or gently bent after extrusion.

And on tolerances, neither alloy is magic: extrusion process capability dominates. But the combination of 6063 and its easier flow often gives die shops more confidence holding tight corner sharpness and consistent wall thickness across long runs.

Look at your real failure modes. Not the imagined ones, the ones tied to standards or past field problems.

If fatigue or ultimate strength truly governs — cranes, highly cycled machine arms, high-load vehicle suspensions — then stepping down from 6061-T6 to 6063-T52 is a major decision. You drop roughly a third to half of your yield strength. You might compensate with heavier sections, but that affects weight, cost and sometimes stiffness distribution.

If corrosion aesthetics govern — think seacoast railings, architect-designed facades, or hardware that can’t be inspected easily — then the small technical advantage of 6063 on corrosion, plus its more consistent anodizing behavior, may dominate the choice.

Often, neither fully governs. You end up in a mixed regime: strength matters a bit, corrosion matters a bit, cost matters a bit, and supply chain reality matters a lot. That’s where an explicit choice per subsystem is more rational than a blanket alloy standard.

Pricing shifts with market conditions, but the pattern that shows up in many supply discussions is simple: 6063 is often slightly cheaper on a per-kilogram basis for standard architectural extrusions; 6061 can be more expensive but is easier to find in heavy or structural shapes and in a wide range of plate and bar sizes.

If your design is extrusion-heavy and shape-driven, 6063 often gives you better die life, higher extrusion speeds and simpler sourcing. If you live in a CNC shop world of plate, bar and structural shapes, 6061 is usually sitting on the rack already.

So sometimes the “right” alloy is simply the one that your fabricator can buy in all the sizes you’ve drawn without special-order lead times.

If the part is a structural workhorse, carries real loads, is machined from plate or bar, or lives in equipment where appearance is secondary, 6061-T6 is the sensible default. You gain a large strength margin, good machinability, and a supply chain that knows it well.

If the part is an extrusion that people see, touch, or judge by its finish — windows, doors, handrails, trims, visible heat sinks, lighting profiles — 6063-T52 is usually a calmer long-term choice. You trade some strength for smoother extrusions, friendlier anodizing and slightly better corrosion behavior.

When a system mixes both needs, a split approach tends to age well: structural members and machined brackets in 6061-T6 where they are hidden, 6063-T52 for the exposed extrusions where the finish and corrosion story matter more than raw strength. Just avoid mixing alloys on the same visible plane when anodizing is involved, unless you enjoy explaining color bands to a client.

That’s really the showdown: not which alloy is “better,” but which risk you’re willing to carry — cosmetic, structural, or supply — on this particular drawing.