Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

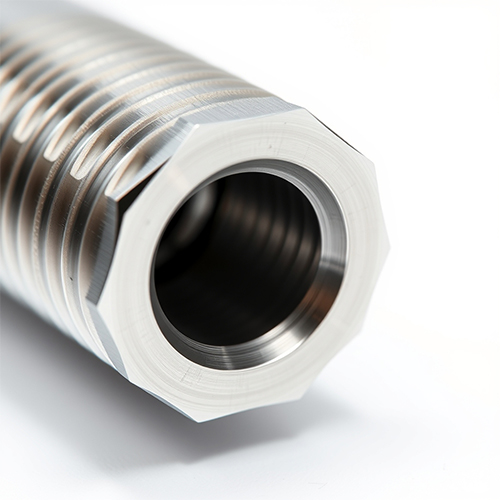

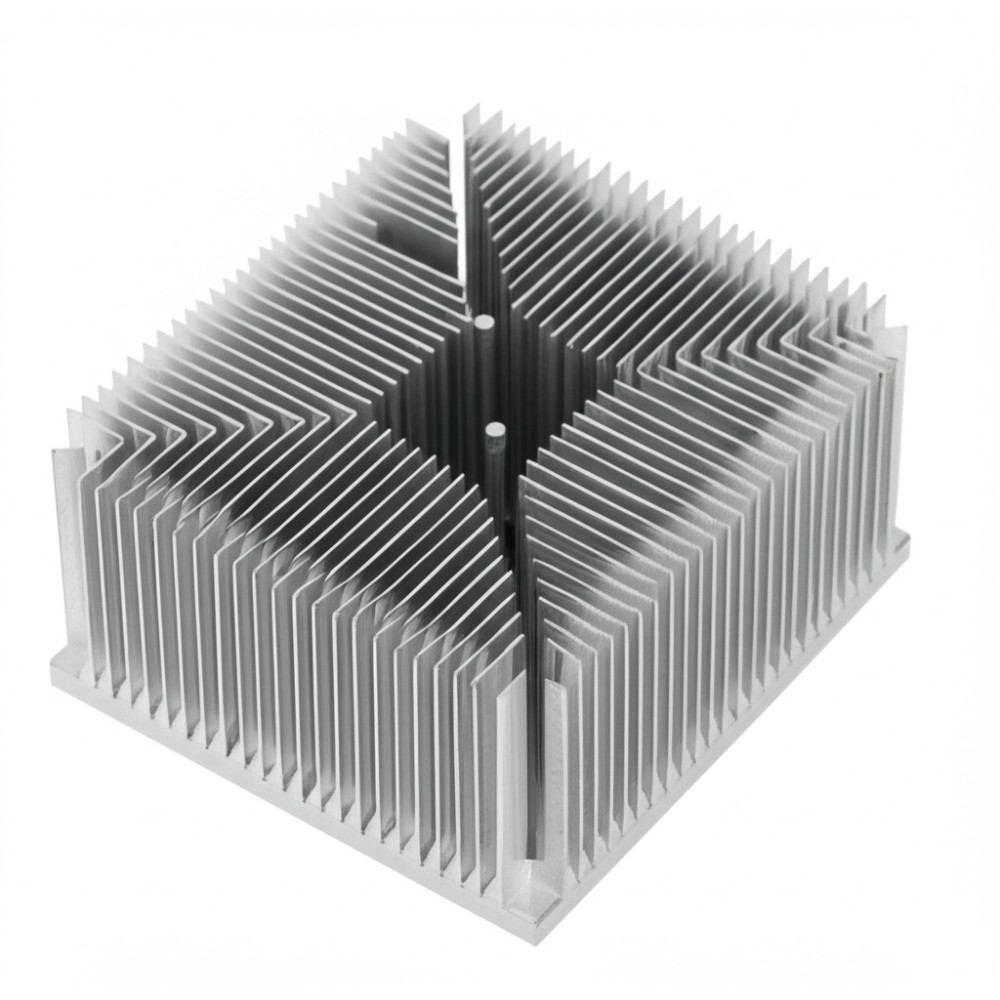

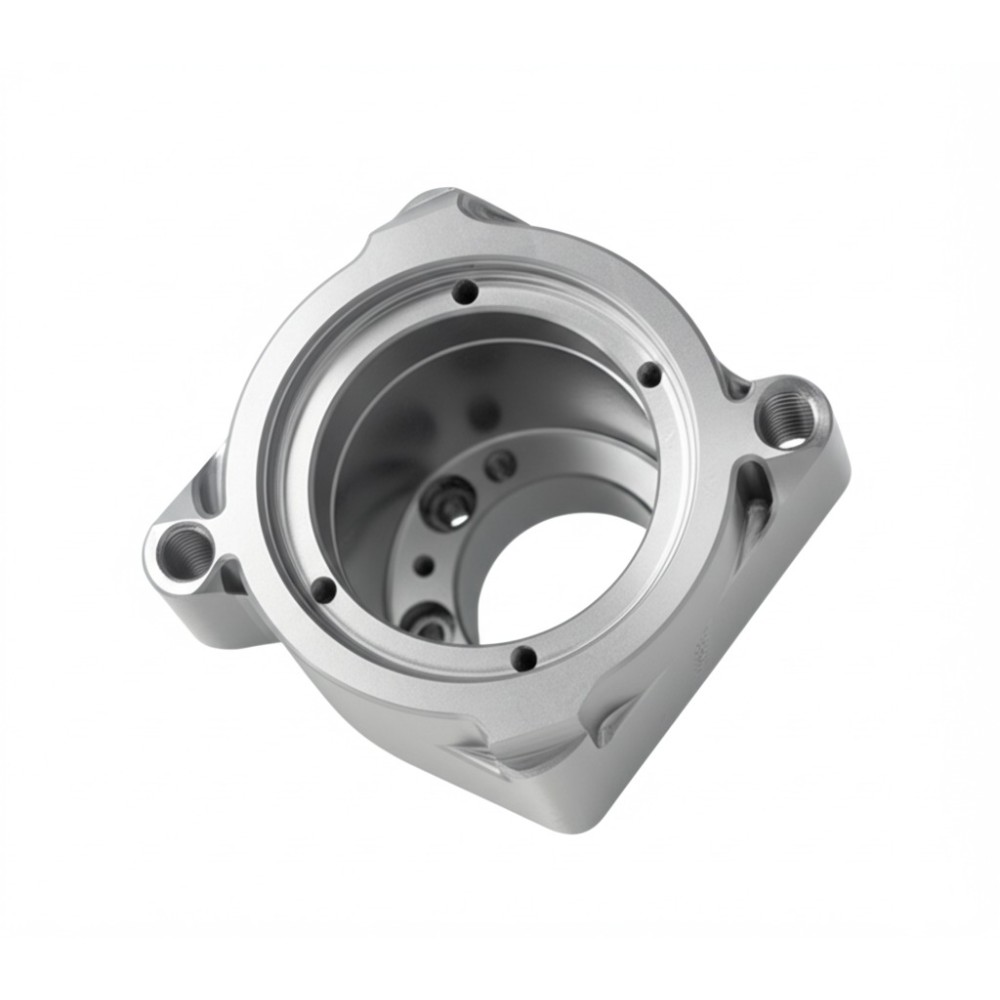

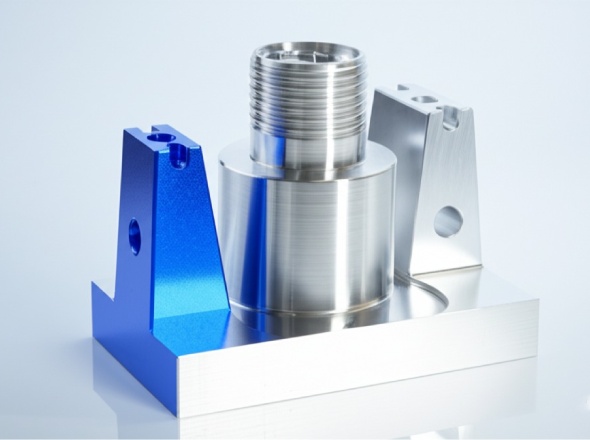

Aluminum CNC machining is when computers control tools to shape aluminum into parts. At Istar Machining, we use special machines to cut, drill, and shape aluminum with high precision.

Our computer-controlled tools follow detailed plans to make perfect parts every time. This is much better than making things by hand!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Aluminum has many great features that make it perfect for many jobs:

These benefits make aluminum a top choice for aerospace cnc machining and many other industries.

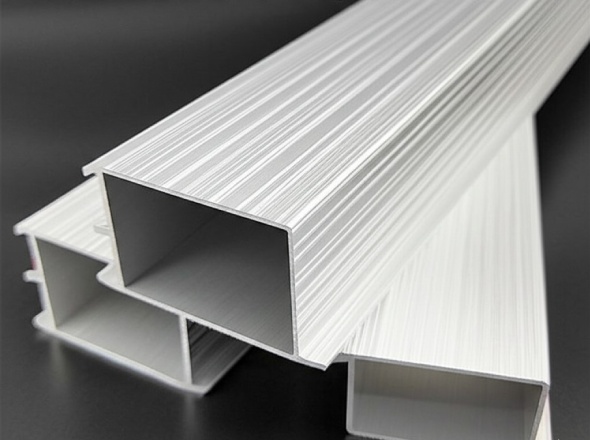

We use different types of aluminum for different jobs:

6061-T6 is the most used type. It is strong. You can weld it. Many cars and planes use it.

This type makes up 40% of all aluminum CNC parts. It is easy to work with. It is good for new makers.

7075 is very strong. It is used for high-stress parts. Planes and army tools use it a lot.

It makes up 25% of the parts in planes. You can cut it well, but not as easy as 6061. It costs more too.

5052 does not rust even in salt water. Boats use it a lot. It makes up 15% of parts in boats.

2024 is for planes.

5083 is for boats.

Both are good for special jobs.

Istar Machining creates aluminum parts for many different fields:

We have top-quality machines that can make almost any aluminum part you need:

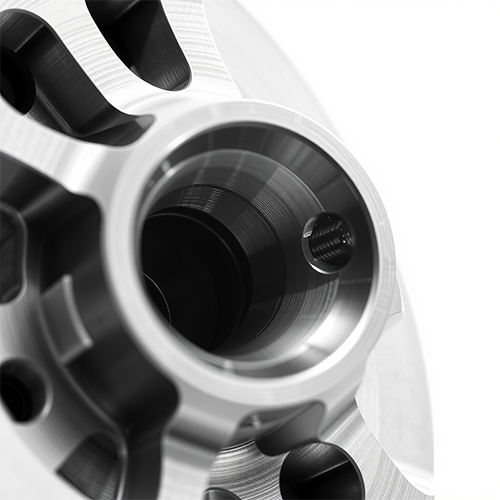

Our 5 axis machining center can create very complex shapes in a single setup.

When we say precision, we mean it:

Raw aluminum is just the start. We offer many ways to finish your parts:

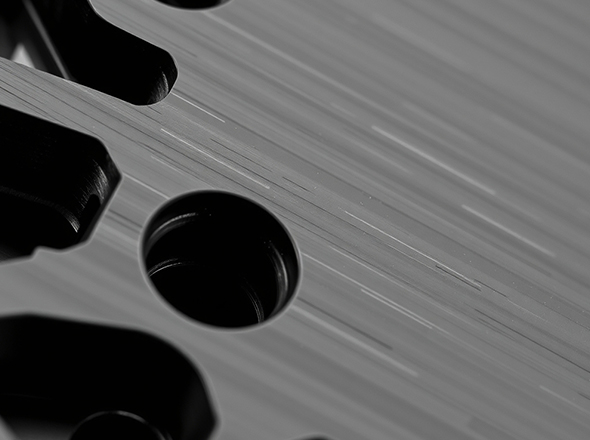

There are many ways to cut aluminum with CNC machines.

Milling uses carbide end mills and PCD tools.

You can cut two ways:

PCD tools last 200% longer than other tools. That saves money in big jobs.

When you drill aluminum, you must get rid of chips. If chips stay, they can stick to the tool.

Tips for good drilling:

Turning is for round parts. You need the right speed. Too fast makes heat. Too slow makes bad cuts.

5-axis machining makes complex shapes. It is good for:

With 5-axis CNC, you can make parts with 99% of the right size.

We know you don't want to wait for your parts:

Prototypes in 3-5 days

Production runs scheduled to meet your deadlines

Quick quotes so you can plan your project

We check every part thoroughly:

In-house inspection with precise measuring tools

Materials tested for strength

Documentation of all quality checks

Quality doesn't have to be expensive:

Competitive pricing

No hidden fees

Volume discounts

Design advice to reduce costs

Our team can help improve your designs:

CAD/CAM expertise

Design for Manufacturing (DFM) guidance

Material selection help

Problem-solving for tricky parts

Here’s how we turn your idea into a finished part:

We look at your plans and suggest improvements

Our experts write the computer code for the machines

Computer-controlled cutting creates your part

Your chosen surface treatments are applied

One last check before shipping

Several things affect the price of your parts:

For the most cost-effective results, talk to our team about your budget early in the process.

Ready to bring your ideas to life with precision aluminum parts? Istar Machining is here to help:

Our team of experts will guide you through the entire process from design to delivery. With our cnc prototype machining services, you can test your ideas before full production.

Contact Istar Machining today and discover why we’re the trusted partner for precision aluminum CNC machining!

7075-T651 is typically the strongest common aluminum alloy we machine. It’s often used in aerospace and high-stress applications.

Standard delivery is 1-2 weeks, but we can make prototypes in as few as 3 days for rush jobs.

Some aluminum alloys approach the strength of mild steel while weighing only one-third as much. For many applications, properly designed aluminum parts work perfectly.

Many options exist including anodizing (clear or colored), powder coating, bead blasting, polishing, painting, and chemical films.

Yes! Aluminum naturally forms an oxide layer that protects it from corrosion. With proper finishing like anodizing, it performs excellently outdoors.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or