Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

I’ve been in the world of making and finishing things for a long time. I can tell you that not much makes an aluminum product look better than a great anodized color. But I also know that getting the right, steady color can be a big challenge. That’s why I’m writing this guide. I want to share what I’ve learned and help you know all about anodized aluminum colors. We will talk about the anodizing process and the hard part of getting the color just right. If you work with aluminum parts, this article will help you avoid problems and save time and money.

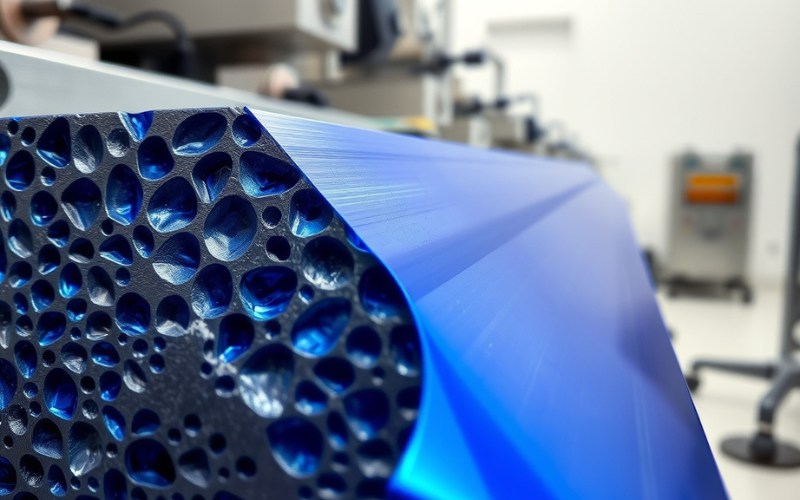

I’ve seen many people get confused about what it means to anodize aluminum. Let me explain it in a simple way. The process of anodizing aluminum is a special method that uses electricity and chemicals. It builds a very strong, protective coat of aluminum oxide on the outside of an aluminum part. You can think of it as rust that we control. We put the aluminum part as the anode (the part with the positive charge) into a tank with a special acid. Then, we send electricity through it. This aluminum anodizing process makes a tough anodized layer with tiny holes. This layer is actually part of the aluminum, not just something painted on top.

This special process is what makes the aluminum product much stronger. It helps it stand up to scratches and damage from weather much better than normal aluminum products. The anodizing is an electrochemical process that changes how the metal is built on the surface. This anodized layer with its small holes lets us put in a nice, lasting color. So, when we talk about anodizing and coloring, it’s a job with two steps. First, we build the strong layer, and then we fill it with color.

This is where the cool part begins. After we make that anodized layer with all the tiny holes, we have a great surface to add color. I’ve used a few ways over the years, and they all have their good points. The most popular way to get a bright anodized aluminum color is by using dye. We just put the anodized part into a tank full of dye. The aluminum oxide layer with its holes soaks up the color just like a sponge. The more time it spends in the dye, the richer the color will be.

Here are the main ways for coloring aluminum after you anodize it:

| Coloring Method | What It Is | Common Colors | How It Holds Up to Sunlight |

|---|---|---|---|

| Dip Coloring | The anodized aluminum parts are put into a tank of special dye. | You can get a very wide range of colors. | Can fade over time if it’s in the sun a lot. |

| Electrolytic Coloring | After anodizing, the part goes into a bath with metal salts. Electricity makes the salts go into the tiny holes. | Usually bronze and black, but other colors can be made. | Very strong and does not fade easily in the sun. |

| Integral Coloring | This way combines anodizing and coloring in one step. | Usually only bronze and black shades. | Resists scratching very well and the color stays true. |

| Interference Coloring | This process changes the tiny holes to make color by how light bounces off. This means the color can seem to change as you look at it from different spots. | Makes a set of light-fast colors ranging from blue, green, and yellow to red. | Holds its color well in the light. |

The last thing we do in the manufacturing process for a colored anodized aluminum part is to seal it. We boil the sealed anodized part in very pure water. This closes the small holes and keeps the color inside. This is a very important step to make it last. If you have unsealed anodized parts, the color can come off or get marks on it easily.

In my workshop, we use three types of anodizing processes. It’s good to know how they are different. This changes the final anodized finish, how thick it is, and how well it takes color. The kind of process we choose to anodize with is based on what the aluminum product will be used for.

The three types of anodizing are:

One of the first things I learned is that not all aluminum alloys are the same when you want to get a nice anodized aluminum color. The kind of aluminum grade you use really changes how the anodizing colors’ appearance turns out. Each aluminum grade has its own natural shade that changes the color match.

Here is a quick guide to how different types of aluminum work with the anodizing process:

This is a problem as old as the process itself, the challenge of anodizing color matching. I have had many customers who were unhappy because of color variation from one group of parts to the next. The real story is that getting a perfect color match every single time is almost not possible. This is why most people in this business talk about a “color range.”

Many things can cause this color variation:

I always explain to my customers that the concept of color matching when you anodize is about getting as near as we can inside a range we agree on. The best way to show the color you want is to give us a real piece to look at.

Even though a perfect color match is hard to get, there are surely things I do to make sure we get the most steady color we can. It is all about being in control. The more things you can control in the anodizing process, the less color variation you will find.

Here are my best tips for getting a steady anodized aluminum color:

By looking closely at these things during the process of anodizing, you can really stop color variation increases and get a much more even aluminum product.

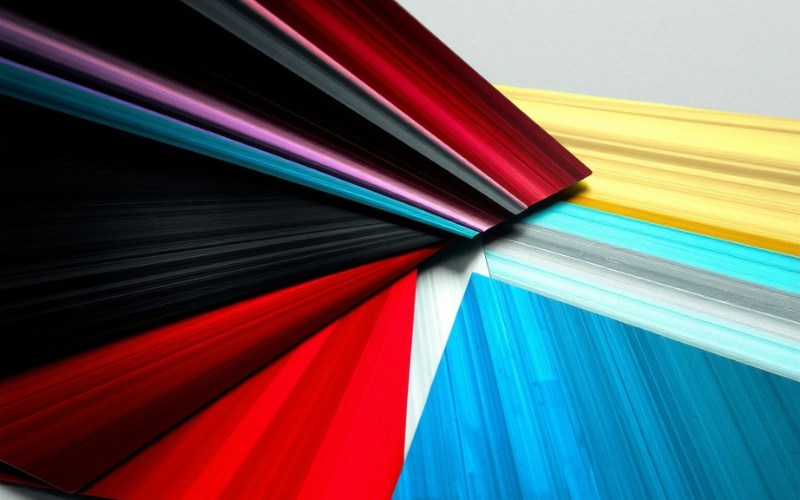

The great thing is that when you anodize aluminum, especially with Type 2 anodizing, you can choose from a full rainbow of colors. You can get a large variety of colors, from common ones like black, blue, and red, to stronger choices like purple, orange, and gold. The available colors for anodized aluminum are many.

Some of the most asked-for colors and finishes I see are:

It is good to know that the colors may seem different based on the aluminum grade and how the surface looks. The anodized layer transmits light to the aluminum at the bottom. So, what you see is a mix of the dye color and the look of the metal under it.

Even though the color options are wide, there are some things you can’t do. Being able to get a certain color really depends on the aluminum alloys you are using. Some mixes will naturally give a darker or more yellow anodized layer. This makes it hard to get very light colors or a real white. The number of colors is limited with some ways of doing it, like electrolytic coloring, which usually makes bronze or black shades.

When a customer asks me for a very exact color, we talk a lot about the aluminum grade they are using. We also talk about the kind of anodizing process that will give the best result. Choosing a color is something we do together. We often make test pieces to be sure the final anodized aluminum color is what they want.

Sometimes, things don’t turn out right, or a customer decides they want a different color for an anodized part they already have. The good part is that color removal can be done. But, it is based on the condition of the anodized product and if it has a sealed anodized coat.

If the part is unsealed anodized, you can often take the dye out with a nitric acid mix. For sealed anodized parts, you usually need to take off the whole anodized layer. You can use a special stripping mix with chromic or phosphoric acid. This can be done without hurting the main aluminum, leaving the aluminum intact. You can also use an alkaline etch, but this might cause slight damage to the aluminum. After taking the layer off, the aluminum part can be anodized and colored again.

From what I’ve seen, colored anodized aluminum is a wonderful pick for many, many uses. Aluminum is widely used, and being able to anodize it makes it useful for even more things. The anodizing process gives a finish that is hard, lasts a long time, and won’t chip or come off like paint. The color is part of the aluminum oxide layer, so it lasts for a very long time.

The properties of an aluminum product get much better when you anodize it. It stops rust better, the surface is harder, and it gives you a lovely, shiny look. It doesn’t matter if you are making phones, parts for buildings, or car parts, the color anodizing process gives you a great mix of good looks and good work. The anodization process allows for many new ideas.