Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

A lathe and a mill. They both looked like big, strong machines that cut metal. But what is the difference? It took me some time to understand it. Now, I want to help you understand faster.

In this article, I will explain the difference between a mill and a lathe in an easy way. We will look at the job of each machine, how it works, and what it is used for. After you read this, you will understand the main jobs of a lathe and a mill. You will know for sure why you would pick one machine instead of the other for your project.

When I first started, a person told me something I will always remember. They said, “On a lathe, the work spins. On a mill, the tool spins.” That is the most important thing to keep in mind. It’s the main difference. It is the reason why these two machines work in their own special ways. The lathe and a milling machine are both used to remove material from a workpiece. But they do this job in different ways.

Think about a potato. If you put it on a fork and spin it while holding a peeler still, you are acting like a lathe. The potato is your workpiece, and it spins around. The peeler is the cutting tool, and it is held still. Now, think about holding the potato still on a table. If you then take a small, spinning cutting tool and move it on the potato to carve it, you are acting like a mill. The potato is held still, and the cutting tool moves and spins. This is the simple difference between a lathe and a mill.

A lathe is a machine that is best for making round or tube-shaped parts. A mill, on the other hand, is great for making flat surfaces, holes, and shapes with a lot of detail. The mill could make a square block. A lathe would make a round baseball bat. The kind of machine you pick depends on the shape of the part you want to make. The lathe and mill are two of the most important machines in a workshop.

A lathe is a type of machine that holds a workpiece and spins it around. As the workpiece spins, a cutting tool that does not move is pushed into it. This action cuts away material and gives the part its shape. Think about a potter’s wheel. The clay spins, and the potter uses their hands (the tool) to shape it. A metal lathe or wood lathe works with the same idea, just with a sharp cutting tool. The lathe machine is a very old and helpful tool.

The main parts of a lathe are the headstock, which holds and spins the workpiece, and the tailstock, which holds up the other end. The cutting tool is held in a tool post. This tool post is on a part that moves from one end of the lathe to the other. I can change the speed of the lathe. I can also change how fast the cutting tool moves. This control lets me cut and shape parts in a very exact way. When the lathe rotates the workpiece, the cutting tool removes material. This makes a smooth, round surface. Lathe operations are jobs like turning, facing, and making a groove.

When you use a lathe, you make a part that is the same all the way around, like a circle. It’s great for things like table legs, baseball bats, or metal shafts for a car engine. The lathe is a type of machine made for these round shapes. The main point is that the workpiece must be able to spin without danger. The lathe is a strong machine, and setting it up right is very important to get good results.

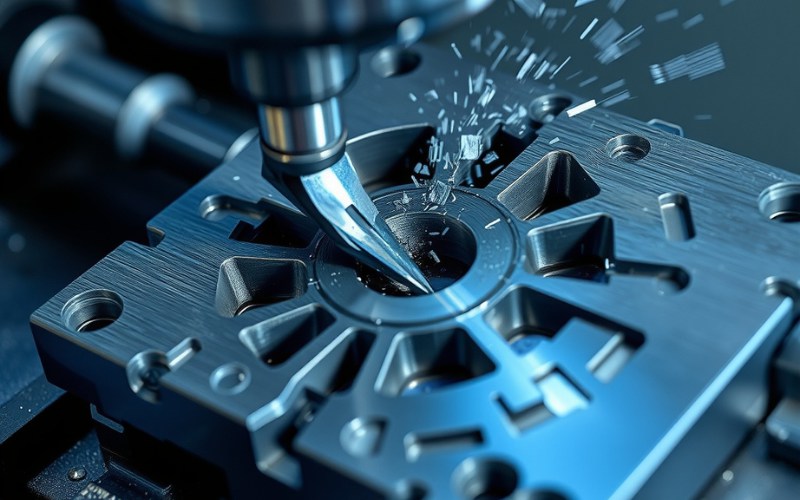

A milling machine works in a different way than a lathe. On a mill, the workpiece is held still on a table. The cutting tool is held in a part called a spindle that spins around at a high speed. This rotating cutting tool is then moved into the workpiece to cut it. A mill is a machine made to cut flat surfaces, drill holes, and make small hollow areas or long cuts. It’s a machine that can do many different jobs.

The table on a milling machine can move in a few directions. It can go left and right, forward and backward, and up and down. This movement lets the cutting tool get to different parts of the workpiece. I can use a mill to make a simple flat surface on a block of metal. I can also use it to make parts that have a lot of small details and tricky shapes. A vertical mill is a very common type of machine in workshops.

A mill can make shapes that a lathe cannot. For example, a mill can cut a square hole into a block of steel. A lathe can’t do that because its part is always spinning. A mill is a machine that cuts in a very exact way, so the parts are the exact size they need to be. Milling operations are very important for making things like engine blocks, molds, and many other machine parts. The mill cuts away material with a spinning tool that has many blades.

The difference between the tool used on a lathe and a mill is very important. It’s one of the main differences between these two machines. On a lathe, the cutting tool is most often a single-bladed cutting tool. It’s a simple piece of very hard material with one sharp edge, and it does not move. This tool is held very tightly in the tool holder, which is called a tool post. The magic happens when the workpiece spins into this still cutting tool.

On a milling machine, the cutting tool itself is the part that spins. A mill uses a multi-bladed or -pointed cutting tool. Examples are an end mill or a face mill. You can think of it as a very strong and exact drill bit that is able to cut sideways. Because the cutting tools rotate, they can cut away material as they move over the workpiece. This rotating cutting tool can have many sharp edges, which are called flutes. This lets a mill take away material in a fast way and make the surface very smooth.

So, in simple words, the tool on a lathe does not move and has one cutting edge. The tool on a milling machine spins and has many cutting edges. This is a very basic and important difference between a milling machine and a lathe. Picking the right cutting tool is very important for both lathe and mill jobs. It helps you get the right shape and a nice finish on the material from the workpiece. The tool moves on a mill, but on a lathe, it stays still.

Choosing to use a lathe or mill is usually easy when you know the shape you need to make. I always ask myself one simple question. “Is the part I want to make mostly round or tube-shaped?” If the answer is yes, I will most likely use a lathe. A lathe is the best machine for making parts that are the same all the way around its middle.

If the part has flat surfaces, square corners, hollow areas, or tricky curves on a surface that isn’t round, then a mill is the right machine. A mill is a machine used for more types of shapes than a lathe. The mill can make almost any shape you can imagine that is not perfectly round.

Here is an easy table to help you choose when to use a lathe or a mill:

| Thing to Make | Best Machine | Why? |

|---|---|---|

| Round Shaft / Rod | Lathe | The lathe spins the workpiece to make a perfect round shape. |

| Flat Surface | Mill | The mill moves a cutting tool over a part that is held still. |

| Screw Threads (on a rod) | Lathe | The lathe can move the tool at an exact speed as the part spins. |

| Square Pocket | Mill | The mill can go down and move sideways to cut out shapes. |

| Gun Barrel | Lathe | A gun barrel is a good example of a long, tube-shaped part. |

| Engine Block | Mill | The mill can make flat surfaces and make exact holes. |

Both mills and lathes are used in all kinds of places. You can find them in small home shops and in huge factories. They can be used to cut metal and wood, and also some plastics. The things they make are all around us every day. When I use a lathe, I am usually making parts that need to be round.

Here are some common things made with a lathe:

A milling machine is used to make parts that are often not round or have more details. A mill can make things that need very exact flat surfaces or holes in just the right spots.

Here are some common things made with a mill:

These are only a few examples. Many detailed parts actually need to be worked on by both a lathe and a mill. For example, I might use a lathe to make a shaft round. Then, I might use a mill to cut a flat spot or a keyway into it. Mills and lathes are often used together.

CNC stands for Computer Numerical Control. A CNC machine is a new type of machine that uses a computer to control how it moves. So, a CNC lathe and a CNC mill are just a lathe and a mill that are controlled by a computer program. I don’t have to turn handles by hand. Instead, I write a program that tells the machine just what to do.

A CNC lathe works just like a hand-controlled lathe, but it can work in a much more exact way. The CNC lathe rotates the workpiece, and the computer controls how the cutting tool moves. This job is often called CNC turning. A CNC mill also works like a hand-controlled mill. The computer controls the table’s movement and where the spindle is. This lets the CNC mill cut very detailed shapes all by itself.

The difference between a CNC lathe and a CNC mill is the same as the difference between the hand-controlled types. The CNC lathe spins the part, and the CNC mill spins the tool. The “CNC” part just means the machine works by itself. This lets us make many parts that are exactly the same in a very fast way and with amazing exactness. This is why a CNC machine is so common in making things today.

This is a very good question. From what I’ve seen, it depends on the job. A CNC machine is not always “better,” but it is often a better and faster way to work for some jobs. If I need to make hundreds of parts that are all the same, a CNC lathe or CNC mill is the best choice. I can write the program one time, and the machine will make copies that are exactly the same over and over. A CNC mill can make each machine part exactly the same.

But, if I only need to make one simple part, a manual machine might be faster. It can sometimes take more time to write and check a computer program than it does to just go to a manual lathe or mill and make the cut. A manual machine is also great for learning. It helps you understand better how the cutting tool removes material from the workpiece.

For very detailed parts, a CNC mill or CNC lathe is almost always better. A computer can control the tool’s movement in ways that a person cannot do by hand. This lets a CNC machine cut more detailed shapes with a better finish. The choice between a manual machine and a CNC machine depends on how many parts you need, how hard the part is to make, and how good the person running the machine is.

Yes, there are machines that do the jobs of both a lathe and a mill. These are often called “multitasking machines” or “mill-turn centers.” These are very high-tech and cost a lot of money, but they can be very, very helpful. A lathe and a mill in one machine can save a lot of time.

These special machines have a main spindle that can spin a workpiece like a lathe. They also have a spinning tool holder that can work like a mill. This means I can do both lathe jobs and mill jobs on a part. I don’t have to move it from one machine to another. This is a very big help because every time you move a part, it might not be as exact.

For a home workshop or a small company, there are also smaller machines that do both jobs. They might not be as strong as two different machines made for just one job each. But they are a great way to save space and money. So yes, you can find a machine that does the work of both a lathe and a mill.

Choosing between a lathe or a mill depends on the final shape of your part. Look at your plan and ask those important questions we talked about. Is it round? Does it have flat sides? Is it the same on all sides? Your answers will help you find the right machine.

If your part is mostly tube-shaped, you should start with a lathe. A lathe is the best and fastest machine for making anything round. Even if the part needs a few small details that a mill could make, like a flat spot or a drilled hole, it’s often best to do the main turning work on the lathe first.

If your part is like a block, has flat surfaces, hollow spots, or tricky curves, the mill is your machine. The mill is the main machine you would use for anything that is not round. Sometimes, the choice is not just a lathe or a mill; you might need to use both. Many projects need to go to the lathe and then to the milling machine to be finished. The most important thing is to understand what each machine is best at doing.

To finish up, let me give you the most important points in a simple list. If you remember these things, you will always know the difference between a mill and a lathe.