Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for a way to make parts faster and better? Arbor CNC milling might be just what you need! This special type of machining helps make complex parts quickly. Let’s learn all about it!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Arbor CNC milling uses a special rod (called an arbor) to hold cutting tools. The arbor spins fast while a computer controls how it moves. This helps make perfect cuts in metal, plastic, and other materials.

What makes it special? We can put multiple tools on one arbor! This means you can do rough cuts and smooth finishing all at once. It’s like having many workers doing different jobs at the same time.

When we use CNC milling services, the machine follows a computer program to make precise cuts. With arbor milling, the cutting happens on a horizontal setup instead of a vertical one.

Here’s how it works:

This setup is perfect for making parts with flat surfaces and deep pockets.

Arbor Type | Details | Best Used For | Speed Range |

MT1, MT2, MT3 | Morse taper connection | Small to medium jobs | 5,000-10,000 RPM |

R8 Taper | Common in many mills | General purpose work | 8,000-12,000 RPM |

ISO 40/50 | Industrial standard | Heavy-duty production | 8,000-15,000 RPM |

HSK63 | Quick-change system | High-speed machining | 10,000-15,000 RPM |

The right arbor type depends on what we are making and how big your part is. At Istar Machining, we help you pick the best setup for your project.

Why choose arbor milling over other types? Here are the big benefits:

One of our customers made helicopter rotor hubs and cut their production time in half by switching to arbor milling!

Our 5-axis machining centers combine these features with multi-directional movement for complex parts.

Different materials are better for different jobs. Our CNC milling capabilities allow us to work with a wide range of materials to meet your specific project needs. Here’s what works best:

Metals

Aluminum (Common Grades: 6061, 7075, 5052, 2024) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

Stainless Steel (Common Grades: 303, 304, 316, 17-4 PH) offers excellent corrosion resistance, high strength, durability, and is easily cleanable/sterilizable. Machinability varies by grade.

Good for:

Why customers love it: “Its superior corrosion resistance and strength make it ideal for harsh environments and applications requiring longevity and hygiene.”

Mild Steel (Low Carbon Steel) (Common Grades: 1018, 1020, A36) is a cost-effective ferrous metal known for its good machinability, weldability, and strength. It requires finishing (like plating or painting) to prevent rust.

Good for:

Why customers love it: “Offers great strength and versatility at a lower cost compared to stainless or alloy steels, perfect for general engineering applications.”

Alloy Steel (Common Grades: 4140, 4340) contains additional alloying elements (like chromium, molybdenum, nickel) enhancing properties like hardness, toughness, and wear resistance compared to mild steel. Often heat-treated for optimal performance.

Good for:

Why customers love it: “Provides enhanced mechanical properties over standard steels, suitable for more demanding, high-stress applications.”

Brass (Common Grades: C360 – Free Machining Brass) is a copper-zinc alloy known for its exceptional machinability, good corrosion resistance, electrical conductivity, and attractive gold-like appearance.

Good for:

Why customers love it: “It’s one of the easiest metals to machine, allowing for fast cycle times and excellent surface finishes, ideal for intricate parts.”

Titanium (Common Grades: Grade 2, Grade 5 – Ti-6Al-4V) boasts an exceptional strength-to-weight ratio, outstanding corrosion resistance (especially to saltwater), and biocompatibility. It is more challenging and costly to machine.

Good for:

Why customers love it: “Unbeatable strength-to-weight ratio and corrosion resistance make it the choice for critical high-performance and biocompatible applications.”

Copper (Common Grades: C101 – OFHC, C110 – ETP) is primarily valued for its outstanding electrical and thermal conductivity. It is soft, ductile, and has good corrosion resistance but can be ‘gummy’ to machine.

Good for:

Why customers love it: “Its superior electrical and thermal conductivity is unmatched for applications requiring efficient energy transfer.”

Plastics

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its toughness, impact resistance, rigidity, and ease of machining and finishing (gluing, painting).

Good for:

Why customers love it: “A versatile and affordable all-rounder plastic, great for prototyping and parts requiring good impact strength.”

Polycarbonate (PC) (Common Trade Names: Lexan®, Makrolon®) is a strong, impact-resistant, and transparent thermoplastic with good temperature resistance.

Good for:

Why customers love it: “Offers exceptional toughness and optical clarity, making it ideal for applications needing high impact resistance and visibility.”

Nylon (PA) (Common Grades: Nylon 6, Nylon 6/6) is known for its excellent wear resistance, high toughness, good chemical resistance, and relatively high strength. It can absorb moisture, affecting dimensional stability.

Good for:

Why customers love it: “Excellent choice for moving parts due to its low friction and high wear resistance, especially in unlubricated applications.”

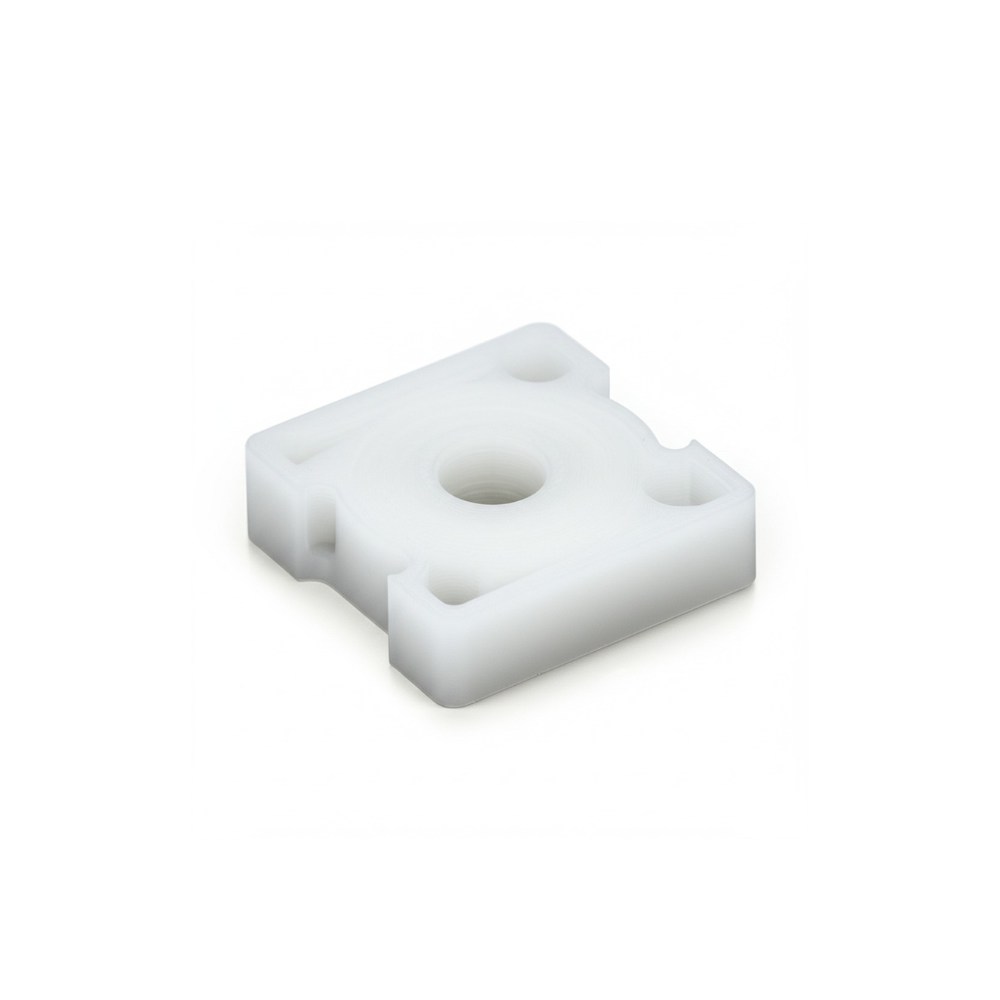

Acetal (POM) (Common Trade Name: Delrin®) is an engineering thermoplastic characterized by its high stiffness, low friction, excellent dimensional stability, fatigue endurance, and great machinability leading to smooth finishes.

Good for:

Why customers love it: “Machines beautifully to tight tolerances and offers great mechanical properties with low friction, ideal for precision mechanical parts.”

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic with exceptional mechanical strength, stiffness, chemical resistance, wear resistance, and performance at high temperatures. It is more expensive and challenging to machine.

Good for:

Why customers love it: “The ultimate choice for extreme environments requiring high strength, temperature resistance, and chemical inertness.”

Acrylic (PMMA) (Common Trade Names: Plexiglas®, Lucite®) is known for its excellent optical clarity, weather resistance, rigidity, and wide range of color options. It’s more brittle than Polycarbonate but easier to polish.

Good for:

Why customers love it: “Offers glass-like clarity and brilliance with easier fabrication and lighter weight, perfect for visual and display applications.”

UHMW PE (Ultra-High Molecular Weight Polyethylene) is recognized for its extremely high abrasion resistance, impact strength, low coefficient of friction, and good chemical resistance. Its softness can make precision machining challenging.

Good for:

Why customers love it: “Incredible wear and abrasion resistance make it last extremely long in high-wear, low-friction applications.”

Arbor CNC milling is used in many industries:

How does arbor milling compare to other types?

At Istar Machining, we offer both vertical milling and arbor milling to handle any type of project.

We follow these tips so we can get the best results from arbor CNC milling:

As a top 5 CNC machining factory in China, Istar Machining provides:

Accuracy down to ±0.0002" (5 µm)

Fast delivery on both prototypes and production runs

Experience with all common engineering materials

Every part inspected to meet exact specifications

Cost-effective manufacturing without quality compromise

Ready to use arbor CNC milling for your next project? Here’s how to get started:

Contact Istar Machining today to learn more about our arbor CNC milling capabilities and how they can help with your manufacturing needs!

CAD files or drawings

Usually within 24 hours

3.We'll start after your go-ahead

Delivered to your door

The key difference is that arbor CNC milling uses a horizontal rod (arbor) that can hold multiple cutting tools simultaneously. This often allows for faster material removal, especially on wide, flat surfaces, compared to typical vertical milling which usually uses one tool at a time in a vertical orientation.

Arbor milling can be faster primarily because multiple cutting tools can be mounted on the same arbor, allowing different operations (like roughing and finishing) or wider cuts to happen in a single pass. This setup is also very stable, permitting more aggressive cutting speeds and feeds, leading to up to 30% faster production compared to some vertical milling methods.

This method is particularly well-suited for parts requiring large flat surfaces, deep pockets, or grooves. It’s commonly used for components in industries like aerospace (engine parts), automotive (transmission housings, engine blocks), medical (implant molds), and energy (turbine components).

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or