Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

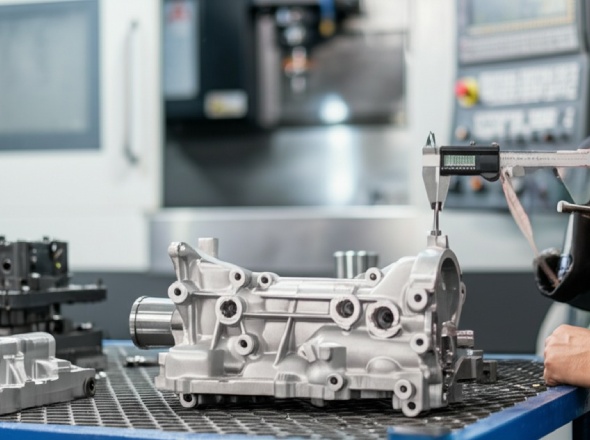

Are you looking for top-quality car parts that last longer and work better? Our automotive CNC machining service makes parts that fit perfectly in your vehicle. Let’s explore how we make these amazing parts and why they’re so important for your car!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Automotive CNC machining uses smart computers to control cutting tools. These tools shape metal and other materials into exact car parts. This is how we make parts for engines, brakes, and many other car systems.

With our 5 axis machining technology, we can create complex shapes that regular machines can’t make. This helps cars run better, use less fuel, and last longer.

Our automotive CNC machined parts stand out because:

We follow all the rules from SAE International and ISO 9001 to make sure every part is safe and works great.

CNC machining offers versatility across a wide range of materials crucial for the demanding automotive sector. From lightweight alloys for efficiency to robust plastics for complex components, we machine the right material for your specific automotive application. Here are some of the common materials we work with:

Metals

(Common Grades: 6061, 7075, 5052, 2024) Aluminum alloys are lightweight, offer excellent corrosion resistance, have good thermal and electrical conductivity, and are highly machinable. Different grades provide varying levels of strength and weldability.

Good for:

Why customers love it: “It offers an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless automotive prototyping and production applications where weight reduction is key.”

(Common Grades: 303, 304, 316, 416, 17-4 PH) Known for its high strength, durability, and excellent corrosion resistance, especially against environmental factors and automotive fluids. Grades vary in machinability, weldability, and specific corrosion resistance (e.g., 316 for harsher environments).

Good for:

Why customers love it: “Its superior corrosion resistance and strength ensure longevity and reliability for critical automotive parts exposed to tough operating conditions and fluids.”

(Common Grades: 4140, 4340) These steels contain additional alloying elements (like chromium, molybdenum, nickel) enhancing properties like hardness, strength, toughness, and wear resistance compared to carbon steels. Often heat-treated for optimal performance.

Good for:

Why customers love it: “Provides exceptional strength, toughness, and wear resistance needed for high-stress automotive powertrain and suspension components, often enhanced through heat treatment.”

(Common Grades: 1018, 1045, A36) A cost-effective ferrous metal offering good strength, weldability, and machinability. It’s less corrosion-resistant than stainless steel and typically heavier than aluminum. 1045 offers higher carbon content and can be heat-treated for increased hardness.

Good for:

Why customers love it: “It’s a highly cost-effective and versatile material with good machinability and weldability, ideal for general-purpose automotive brackets, fixtures, and structural parts.”

(Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) Offers an exceptional strength-to-weight ratio, excellent corrosion resistance (especially to salt water and many chemicals), and good performance at elevated temperatures. It is more challenging and expensive to machine than aluminum or steel.

Good for:

Why customers love it: “Its incredible strength-to-weight ratio and high temperature/corrosion resistance make it the ultimate choice for reducing weight in critical, high-performance automotive applications where cost is secondary.”

(Common Grades: C360) An alloy of copper and zinc, known for its excellent machinability (“free-machining” grades like C360), good corrosion resistance, electrical conductivity, and aesthetic appeal. It’s denser than aluminum.

Good for:

Why customers love it: “It machines exceptionally easily and quickly, reducing costs for complex parts, while providing good corrosion resistance and electrical properties for fittings and connectors.”

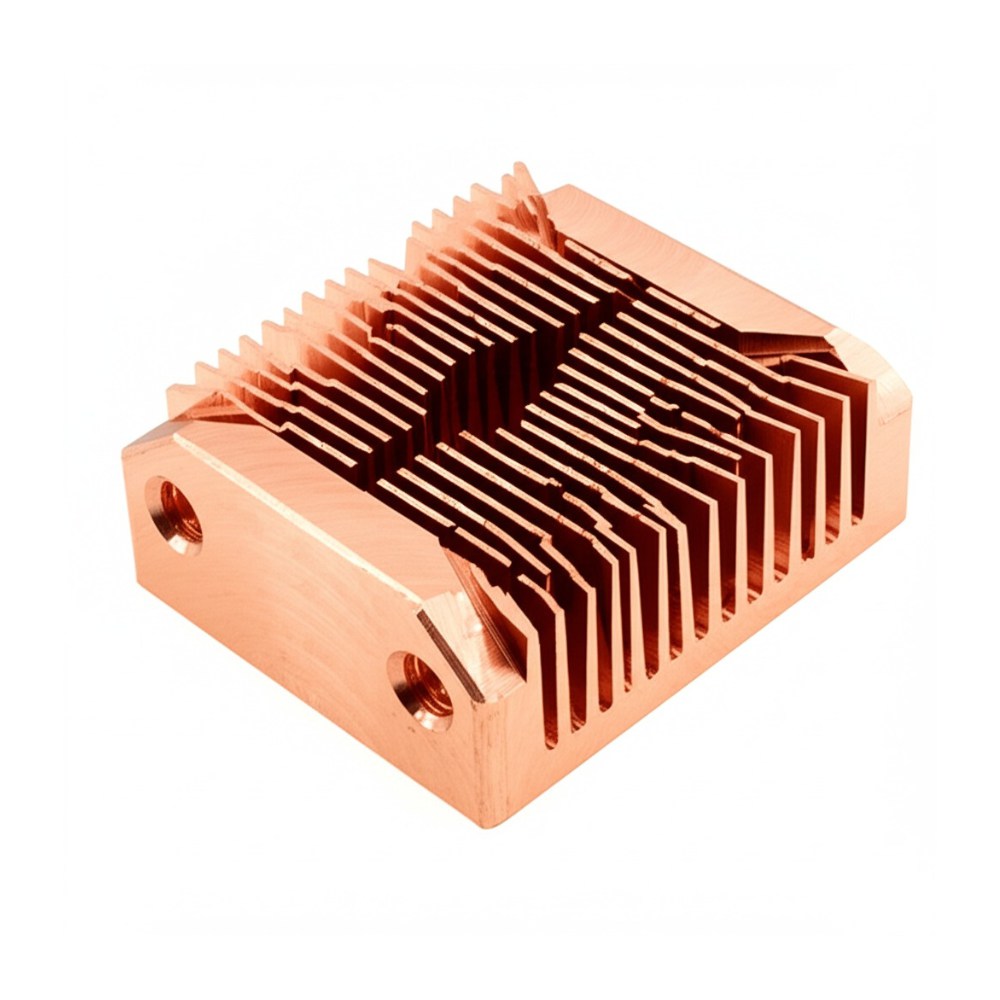

(Common Grades: C101 (OFHC), C110 (ETP)) Primarily known for its outstanding electrical and thermal conductivity, second only to silver. It also offers good corrosion resistance and machinability, although it can be ‘gummy’.

Good for:

Why customers love it: “Unbeatable electrical and thermal conductivity makes it essential for automotive electrical systems and thermal management components where efficient energy or heat transfer is paramount.”

Plastics

A common thermoplastic known for its good impact resistance, toughness, rigidity, and ease of machining. It’s relatively low-cost and available in various grades. Limited chemical and UV resistance compared to other engineering plastics.

Good for:

Why customers love it: “It’s a cost-effective and easily machined plastic, great for prototyping and producing tough, impact-resistant interior automotive components and housings.”

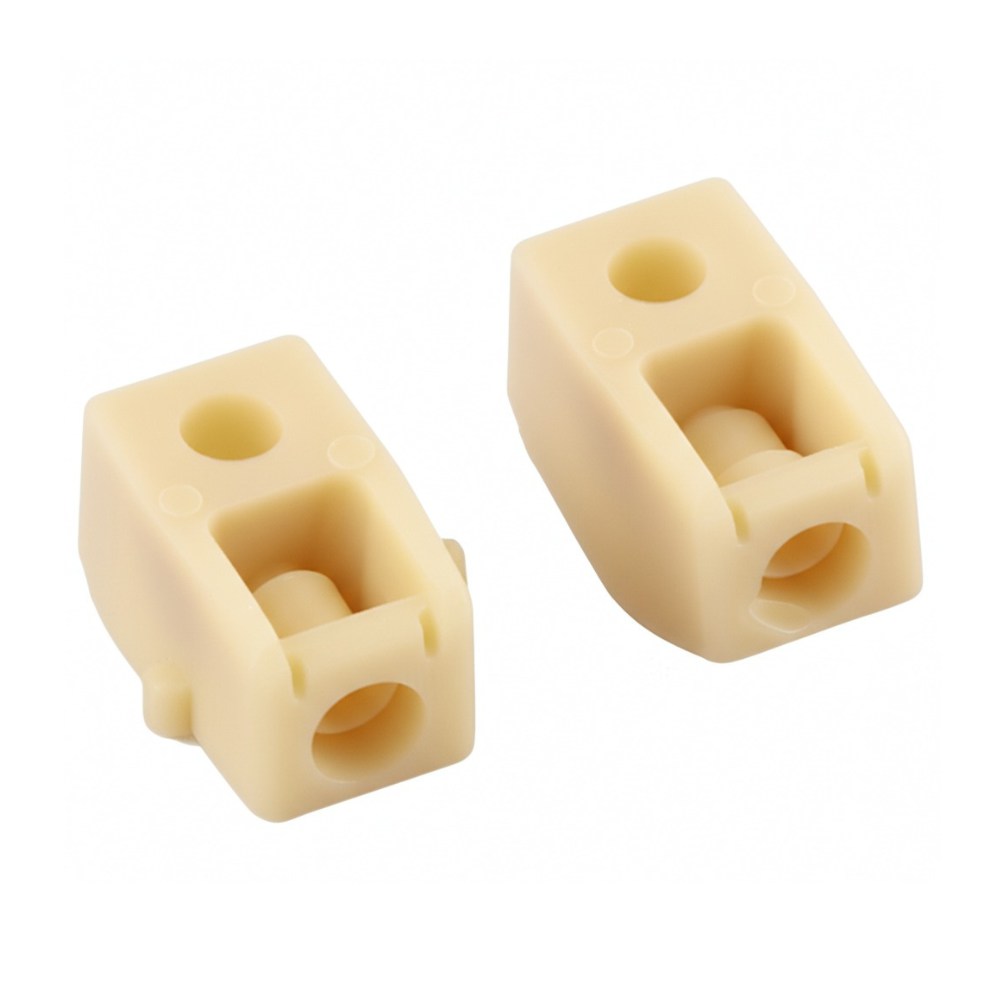

(Common Grades: PA6, PA66, Glass-Filled Variants) A strong, stiff engineering thermoplastic with excellent wear resistance, good chemical resistance (especially to oils and fuels), and a low coefficient of friction. Can absorb moisture, which may affect dimensional stability. Glass-filled variants offer increased stiffness and strength.

Good for:

Why customers love it: “Its excellent wear resistance, toughness, and chemical inertness make it ideal for durable, low-friction moving parts like gears and bushings in automotive applications.”

A strong, extremely impact-resistant thermoplastic that maintains rigidity over a wide temperature range. Can be optically clear. Requires specific tooling/techniques for good machining results. Susceptible to scratching and certain chemicals.

Good for:

Why customers love it: “Offers exceptional impact strength and toughness, providing robust protection for sensitive components, while clear grades offer options for visual elements.”

A high-performance engineering thermoplastic with outstanding mechanical strength, stiffness, chemical resistance, wear resistance, and performance at high temperatures (up to 250°C continuous). It’s expensive and requires care in machining.

Good for:

Why customers love it: “Its exceptional performance at high temperatures, combined with excellent strength and chemical resistance, allows it to replace metal in demanding automotive powertrain and under-hood applications.”

(Copolymer – POM-C, Homopolymer – POM-H / Delrin®) Known for its excellent machinability, high stiffness, low friction, good wear resistance, and excellent dimensional stability (low moisture absorption). Good resistance to fuels and solvents.

Good for:

Why customers love it: “Delrin®/Acetal machines beautifully to tight tolerances and offers a great combination of stiffness, low friction, and dimensional stability, perfect for precision automotive components like gears and bushings.”

A thermoplastic known for its extremely high abrasion resistance, impact strength, and very low coefficient of friction. It also has good chemical resistance but relatively low tensile strength and temperature resistance compared to engineering plastics like Nylon or PEEK. Can be challenging to machine to very fine finishes.

Good for:

Why customers love it: “Its incredible abrasion resistance and low friction make it ideal for automotive-related applications involving sliding contact and wear, such as guides and wear strips, significantly outlasting many other materials.”

Our CNC machining can create almost any part for your vehicle:

1. Battery trays that keep batteries safe

2. Motor housings that don't overheat

3. Charging ports that connect perfectly

1. Custom pistons that boost power

2. Special gearbox parts for faster shifting

3. Lightweight suspension parts for better handling

1. Brake calipers that stop better

2. Steering parts that last longer

3. Turbo parts that give more power

Our process uses the latest technology to make your parts exactly right:

Our tight tolerance machining means parts fit together perfectly – sometimes within 0.005mm! That’s thinner than a human hair!

When you work with us, you get:

We work with both big car makers and small repair shops. Our cnc auto parts are used in vehicles around the world!

5-axis CNC Milling machines like the Haas UMC-750

High-Speed Turning equipment for round parts

Surface Finishing robots for perfect surfaces

Digital Twin technology to test parts virtually

IoT-enabled monitoring to ensure quality

Ready to get better parts for your vehicle? Our automotive precision machining experts are ready to help you today!

Whether you need parts for an old classic car or the newest electric vehicle, our CNC machining technology can create exactly what you need.

Contact us now to get a free quote and see how our automotive CNC machined parts can improve your vehicle’s performance!

Yes! We specialize in EV battery enclosures, motor components, and lightweight parts that help electric cars go farther.

We work with STEP, IGES, SOLIDWORKS, and AutoCAD files. Just send us your design and we can start making your parts.

We make everything from one-off prototypes to 10,000+ unit batches. Our process works for both small and large orders.

For urgent orders, our rapid prototyping service can deliver parts in just 3-5 days. Standard orders typically take 1-2 weeks.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or