Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

In this guide, we will look at the best CAD and CAM software. You will learn what you need. You will find the best solution for your projects. This comprehensive guide will help you choose the right tools.

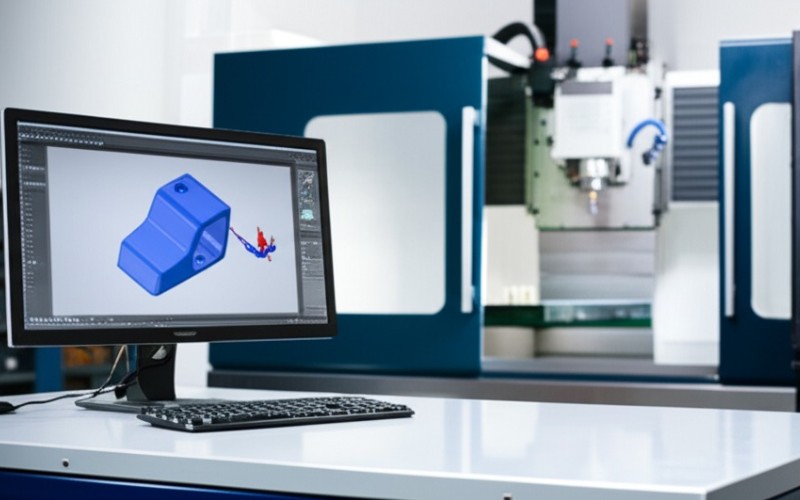

Let’s start with the basics. You need software to run a CNC machine. This software comes in two main parts. The first part is CAD. CAD stands for computer-aided design. Think of it like a pencil and paper, but on your computer. You use CAD software to draw your ideas. You design parts you want to make. This is the “what to make” part of the process.

The second part is CAM. CAM stands for computer-aided manufacturing. The CAM software is the “how to make it” part. It takes your drawing from the CAD software. Then, it creates a set of instructions for the CNC machine. These instructions are called a toolpath. The CAM software tells the machine where to move, how fast to go, and how deep to cut. Without CAM software, your CNC machine is just a quiet box. The software used is very important for the whole manufacturing process.

The first step in any project is the design. This happens in your CAD program. You can make a simple 2D drawing. This could be a sign with letters. Or you can make a complex 3D model. This could be a gear or a custom part for a car. Your CAD software is where your idea takes shape. You can change it. You can measure it. You can make sure it is perfect before you make a single cut. This is a key step to get precision.

There are various CAD packages to choose from. Some are great for simple 2D CAD. Others are full 3D CAD software systems. When you are done with your design, you save it. This makes a digital file, like a blueprint. These CAD files are what the CAM software will use. The CAD functionality of your chosen CAD package will decide what you can create. Good CAD software for beginners should be easy to learn. It helps to have a clear user interface. You can design almost anything, from a wood carving on a CNC router to a metal part on a mill.

Once you have your drawing, you need to tell your CNC machine how to make it. This is the job of the CAM software. I think of CAM software as the translator. It translates your drawing into a language the CNC machine can understand. This language is called G-code. G-code is a long list of commands. Each command tells the machine to move to a spot. It controls the whole cutting process. The CAM software is very smart. It helps you create the toolpaths.

The CAM software lets you choose your tools. You can tell it you are using a small bit for fine details. Or a big bit for clearing away lots of material. The software then creates the G-code based on your choices. This CAM program is key for making a good part. Good CAM software will help you make an efficient toolpath. This saves time and makes your cuts clean. This whole process is called computer-aided manufacturing. It’s the brain behind the CNC machine. Without good CAM software for CNC, your machine cannot work.

There are great free options. Many people start with free CAD programs to learn the basics. A very popular choice is Autodesk Fusion. Fusion offers a free license for personal or hobby use. This is amazing. It is a very powerful professional CAD and CAM package in one. You get great tools without paying anything.

There are other options for free cam software, too. Some are very simple. They are made for specific machines, like a basic 3-axis CNC router. These are great for learning. They let you import a 2D design and create a simple toolpath. While free software is great, it can have limits. A paid software package might offer more advanced features or better support. But for starting out, you can do a lot with a free cam package.

Choosing the right software for CNC machining is a big decision. The first thing I look for is ease of use. The software should be easy to learn. It should have a clean interface. If you spend all your time fighting the software, you won’t get anything made. Look for a program with good tutorials. A big user community is also a big help. You can ask questions and get help from others.

Next, think about what you want to make. Do you need to do complex 3D work? Or just simple 2D cutting? Your projects will decide what features you need. Also, think about the types of CNC machines you have. Some CAM software is better for a CNC router. Other CAM software is better for milling machines. The best CNC software is the one that fits your work and your CNC machine. Check if the software available supports your specific machine.

I have mentioned Autodesk Fusion a few times. There is a good reason for that. For many people, Fusion is the best CAD and CAM software out there. One of the best things is that CAD and CAM are in one program. This creates a seamless integration. You can design your part. Then, you can switch to the CAM workspace with one click. There is no need to export or import files between different programs. This makes the workflow so much smoother.

Fusion is also cloud-based. This means you can access your projects from any computer. Autodesk has packed it with features. You can do simple 2D designs. You can do advanced 3D modeling. You can even design for sheet metal or 3d printing. The CAM software inside Fusion is also very powerful. It can handle simple jobs on a 3-axis CNC machine or complex work on a 5-axis CNC machine. When you need to generate g-code, Fusion makes it easy. For many people, Fusion might be the best choice.

Yes, you can. For a long time, this was the only way to do it. Many professional machine shops still work this way. They might have one person who is an expert in a specific CAD program. They use this CAD package to create a very detailed CAD model. Then, they give that file to a machinist. The machinist uses a separate, powerful cam package like Mastercam to create the toolpaths.

This workflow can be very powerful. You can pick the absolute best CAD tool for design. Then you can pick the most powerful CAM software for machining. The downside is that it can be more complex. You need to make sure the files transfer well. If you make a change to the design in the CAD software, you have to re-import it into the CAM software and redo the toolpaths. For a beginner, an all-in-one software package like Fusion is often an easier starting point. The transition from CAD to CAM is much simpler.

This is one of my favorite features. Before you send your code to your expensive CNC machine, you should run a simulation. Almost all good CAM software has a simulation feature. It shows you a video of the cutting process. You can see the virtual tool moving along the toolpath. You can see it cutting away the material from your virtual block.

Why is this so important? The simulation shows you mistakes before they happen. It can show you if your tool is going to crash into the part. It can show you if you are cutting too deep. It can show you if you will be left with material where you don’t want it. Watching the simulation gives you confidence. You know the code you send to your CNC machine is correct. This is key to getting a good part and protecting your accurate machine. It helps you achieve high precision.

If you are new to this, my advice is to keep it simple. Do not try to learn the most complex software for CNC right away. You will get frustrated. Look for CAD software for beginners. The best solution is often software that combines CAD and CAM. This makes the learning process much easier. As I said, Autodesk Fusion is a top choice because it does this so well and has a free version. It offers an easy workflow.

Another thing to look for is a short learning curve. How quickly can you go from opening the software to making your first part? Some software options are designed to be very simple. They may not have all the bells and whistles, but they will get your CNC machine cutting. Look for inexpensive CAD or even free options. Don’t spend a lot of money until you know what you really need. The goal is to start making things. The software is right if it helps you do that. You can find the best software for you by trying a few out. Many offer a free trial.

You have picked your CAD and CAM software. Great! Now the real fun begins. The next step is to practice. Don’t try to make a masterpiece on your first day. Start with something simple. Draw a square or a circle in your CAD software. Then, take that simple shape into the CAM software. Learn how to create a simple toolpath. Learn how to set your tools and speeds. Run the simulation.

Once you are comfortable, generate G-code for that simple shape. Do a test cut on a cheap piece of wood or foam. This lets you see how the digital design becomes a real object. This is a big moment for every new machinist. From there, you can try more complex shapes. You can learn about different kinds of toolpaths. The software you use is a tool. The more you practice with it, the better you will get. Soon, you will be making all the amazing things you imagined. This is how you master the CNC programming for your CNC machine.