Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

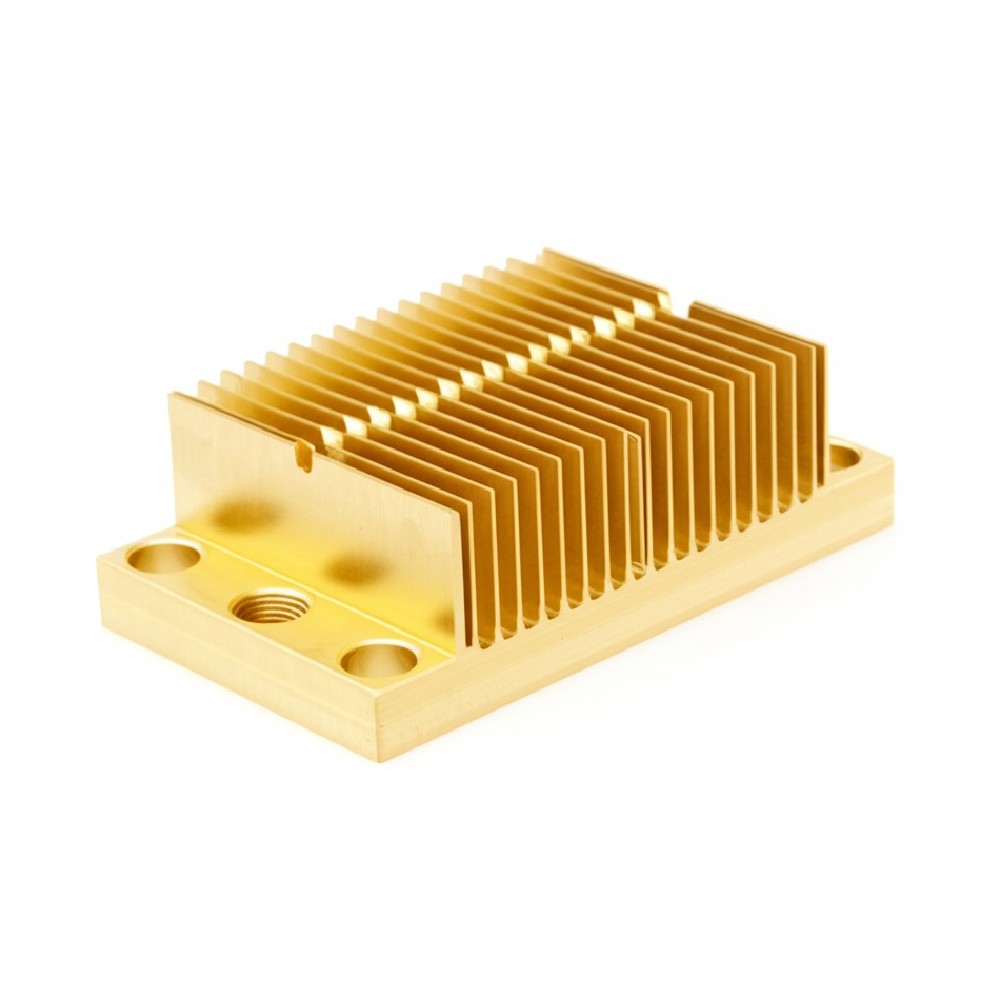

Are you looking for top-quality brass parts that last longer and look better? At Istar Machining, we make amazing brass parts using special computers and machines. Let’s learn all about brass CNC machining and why it’s so great for making things!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

We use many different methods to make your brass parts perfect:

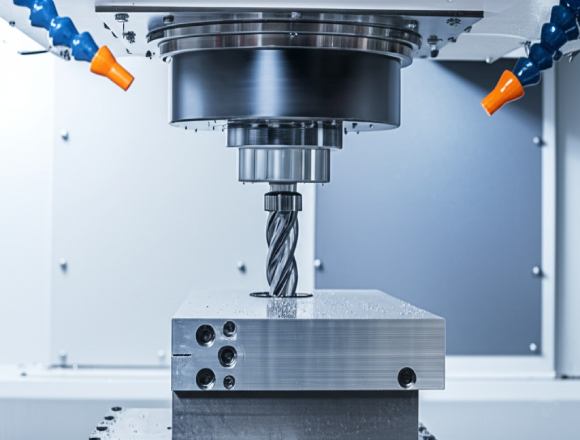

With CNC milling brass, we cut away brass material to create your part. Our machines can move in multiple directions at once to make complex shapes.

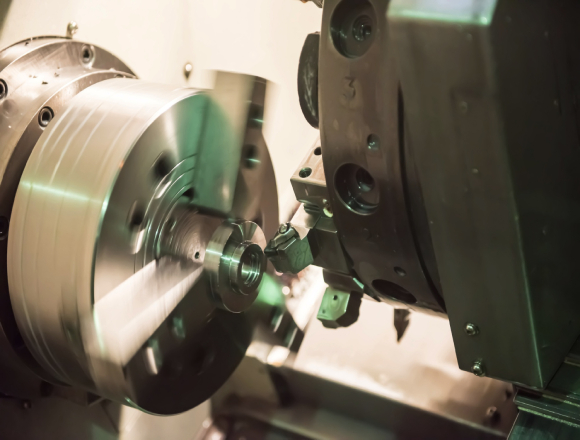

For round parts like rods, tubes, or anything that needs to be cylindrical, we use CNC turning.

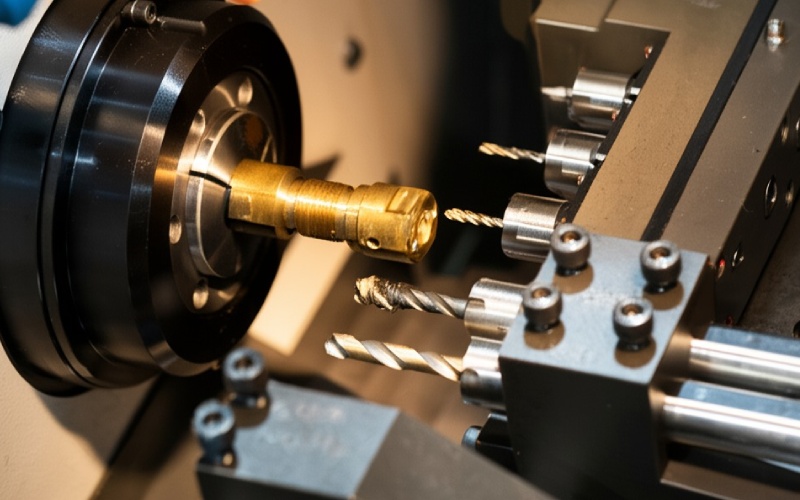

For tiny, super-precise brass parts, we use Swiss machining which is perfect for:

Small medical parts

Watch components

Small electrical connectors

Delicate instrument parts

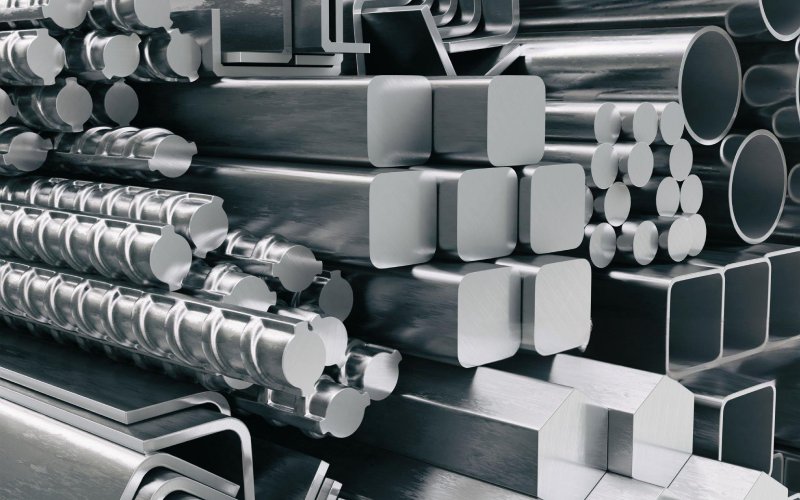

There are many kinds of brass. Each one is good for different jobs. Let’s look at the best ones:

C360 is the best brass for most CNC jobs. It has:

This brass cuts the best of all. Tools last longer when cutting C360. It is the top pick for:

C260 has:

This brass bends well without breaking. It is good for:

This brass works great near salt water:

The tin helps it not rust in water. Use it for:

This is a green brass with no lead:

It is good for:

This has the most copper:

It looks more red than other brass. Use it for:

Here is a simple chart to help you pick the right brass:

| Brass Type | Cuts Easy? | Rust Proof? | Cost | Best For |

|---|---|---|---|---|

| C360 Free-Cutting | ★★★★★ | ★★★ | $$$ | Most parts |

| C260 Cartridge | ★★★★ | ★★★★ | $$ | Bendy parts |

| C464 Naval | ★★★ | ★★★★★ | $$$$ | Wet places |

| C693 Eco | ★★★★ | ★★★★ | $$ | Safe parts |

| C230 Red | ★★★ | ★★★★ | $$$ | Hot parts |

Brass parts are used in many different industries:

Brass is an awesome metal for many reasons:

Doesn’t make sparks – safe for places with flammable stuff

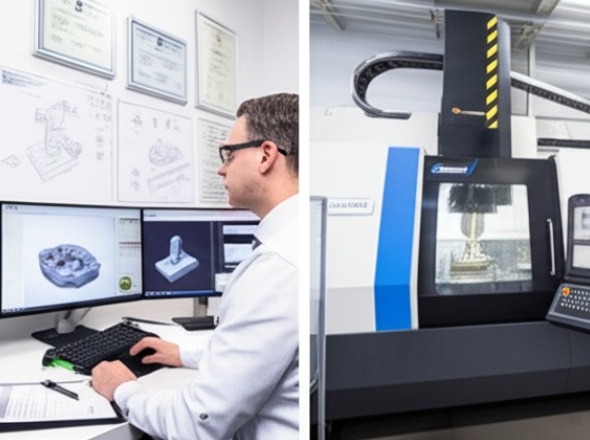

At Istar Machining, we make sure every brass part meets the highest standards:

We handle every step of making your brass parts:

1. Design Help

Our engineers will help improve your designs to:

2. Prototyping

With our CNC prototype machining services, you can test your designs quickly:

3. Production

When you’re ready for full production:

If you’re an engineer, you’ll appreciate these technical details:

Capability | Specifications |

Tolerances | Down to ±0.005mm (ISO 2768 fine) |

Surface Finish | As smooth as Ra 0.4 μm |

Minimum Wall Thickness | As thin as 0.3mm |

Thread Sizes | From M1 to M42 |

Part Size Range | From 1mm to 500mm |

CAD Formats | STEP, IGES, SolidWorks, AutoCAD |

Machine Types | 5-axis CNC centers, Swiss lathes, EDM |

Inspection | CMM machines, surface roughness testers |

We’re the best choice for your brass parts because:

Years of experience making precision brass parts

Latest CNC machines for perfect results

Access to all brass grades and alloys

Rigorous testing of every part

Helpful support from start to finish

Competitive rates without sacrificing quality

Ready to get amazing brass parts for your project? Here’s how to start:

CAD file or even a sketch

usually within 24 hours

we'll suggest any improvements

with careful quality checks

to anywhere in the world

Don’t wait to get the perfect brass parts for your project. Contact Istar Machining today:

At Istar Machining, we turn your brass part ideas into reality with precision, quality, and care.

Brass CNC machining is when we use smart computers to control machines that cut and shape brass metal into parts you need. The machines follow exact instructions to make perfect parts every time. At Istar Machining’s CNC machining service, we make brass parts that fit just right and work perfectly.

Brass is made from copper and zinc, while bronze is copper and tin. Brass is usually yellow-gold in color and is easier to machine.

Brass costs more than steel but less than copper. The easy machining saves money on production costs.

Yes! Brass is 100% recyclable, making it an environmentally friendly choice.

With proper care, brass parts can last for decades without corroding or failing.

Absolutely! We can create custom brass decorative elements with beautiful finishes.

If you care more about appearance, corrosion margin and extrusion-friendly shapes, 6063-T52 usually wins. If you care more about structural

If you work in construction, fabrication, CNC machining, product design, or procurement, you’ve probably hit this exact moment: “The drawing

You almost never choose between a bearing and a bushing because of friction alone. You choose because of how you