Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Have you ever asked yourself why a glass shatters when it strikes the floor, yet a plastic mug might simply bounce? The response depends on a remarkable residential property of materials called brittleness . Recognizing brittleness is not simply an academic workout; it’s crucial for developing and choosing materials for whatever from buildings to electronics. This short article will take you on a trip to understand what makes a product brittle, why it matters, and just how it shapes the world around us. We’ll check out why some products can flex and extend while others snap in an instant.

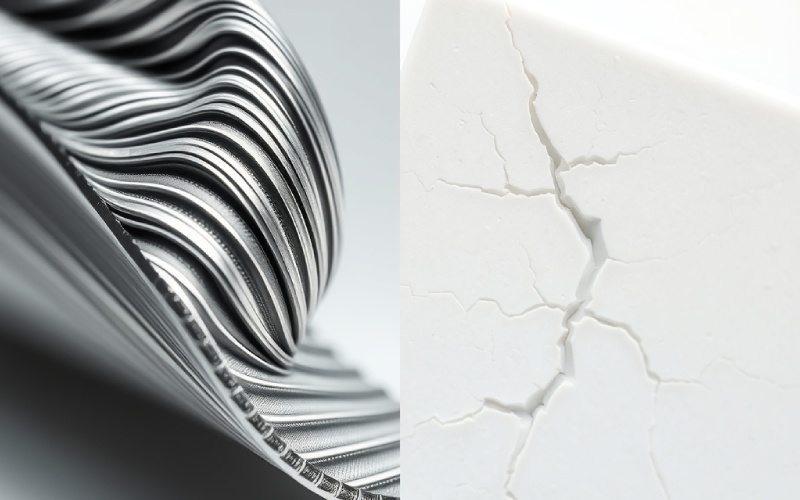

I have actually located the best method to think about brittleness is to picture a completely dry twig. When you bend it, it does not gracefully curve; it snaps. That, basically, is brittleness . On the planet of materials science , brittleness is the property of a product that causes it to fracture when based on stress with very little flexible contortion and no considerable plastic contortion . This suggests a brittle material will certainly break without much warning. Unlike ductile materials, which stretch and deform prior to damaging, weak ones simply fail all of a sudden.

This absence of plastic deformation is a vital identifier. When a brittle material breaks, the two pieces can often be fitted back with each other perfectly because the material really did not stretch or change form prior to the fracture . This lack of ability to deform plastically is a core quality of brittleness . It’s an essential principle in mechanical design and product choice due to the fact that an abrupt, unforeseen failure can be tragic. The brittleness of a material is a vital aspect to think about in any layout.

Establishing if a product is ductile or breakable is a basic task in materials science . I commonly rely on the outcomes of a tensile examination . In this examination, a sample of the material is pulled apart up until it breaks. The amount it extends before fracturing informs us a lot. A brittle material will show extremely little elongation, or strain , prior to it fractures. A ductile material , on the various other hand, will extend and deform significantly.

We can additionally consider the stress-strain contour, a graph that demonstrates how a material replies to a lots. For a brittle material , this contour is often a high, straight line that ends suddenly at the point of fracture . There is no “necking,” or thinning down, before it damages, which is a classic sign of a ductile failing. A material’s ductility is essentially the reverse of its brittleness . So, if a material has reduced ductility , it is considered to have high brittleness .

| Building | Brittle Material | Ductile Product |

| Contortion Before Fracture | Very little to none | Considerable |

| Caution Prior To Failure | Little to no warning | Obvious signs of deformation |

| Power Absorption | Low | High |

| Fracture Surface area | Typically level and rough | Frequently harsh and coarse |

| Instances | Glass, Ceramics, Cast Iron | Steel, Light Weight Aluminum, Copper |

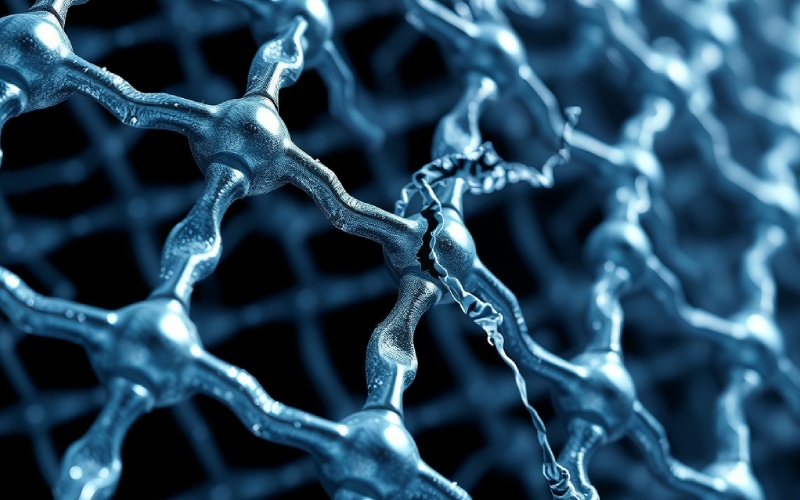

The sources of brittleness are rooted deep within the product at the atomic level. The method atoms are bound with each other has a huge affect on just how the product acts under stress . In lots of breakable materials , like ceramics , the atoms are held together by extremely solid ionic or covalent bonds. These bonds are very inflexible and do not permit the atoms to move previous each other quickly. This resistance to atomic slip is a key reason for high brittleness .

A material’s crystal structure likewise plays a substantial duty. Materials with a complex crystal framework and fewer slip systems (planes along which atoms can move) often tend to be more brittle. In addition, the presence of tiny flaws, such as tiny cracks or impurities at the grain limits , can work as stress concentrators. When stress is used , these imperfections can quickly grow and lead to an unexpected fracture , a phenomenon central to the field of fracture auto mechanics . This is why also a little scratch on an item of glass can make it much easier to damage.

Yes, ceramics are classic examples of a brittle material . When I consider brittleness , materials like glass, ceramic, and concrete instantly enter your mind. These materials are recognized for their solidity and high compressive toughness , but they have a really reduced tolerance for tensile stress . The solid ionic and covalent bonds within their atomic framework are what make ceramics so hard, however likewise what provides their particular brittleness .

These solid bonds stop the type of atomic movement, or dislocation, that enables steels to deform plastically . As a result, when you use sufficient stress to a ceramic item, as opposed to bending, it will certainly fracture . This brittle actions is a defining quality of many ceramic materials. While their brittleness can be a limitation, it doesn’t stop them from being unbelievably useful in applications where their various other homes, like warmth resistance and firmness, are more vital.

You experience examples of brittleness every day, commonly without recognizing it. Right here are some typical instances of brittle materials :.

Recognizing these different sorts of weak materials is key in developing and picking materials for particular jobs.

The brittleness of a material has a profound influence on product option . In my experience, you have to thoroughly evaluate the pros and cons. Weak products are typically picked for their high stamina, solidity, and resistance to use. Nevertheless, their propensity to stop working without alerting makes them inappropriate for applications where they might be based on abrupt influences or high tensile stress .

For example, you would not develop a bridge out of an extremely brittle material due to the fact that the dynamic tons from website traffic might cause a catastrophic brittle failing . Rather, engineers select even more ductile products like steel that will certainly bend and show signs of distress long prior to they break. The idea of brittleness pressures developers to consider failing modes. If a part’s failure might be unsafe, a much more ductile material is often the safer choice. The risk of weak fracture is a significant consideration in many design areas.

The unexpected nature of a brittle fracture is one of its most defining– and hazardous– characteristics. The reason products fracture by doing this is as a result of how fractures relocate through them. In a brittle material , when a split begins, it can travel with the material very promptly. This quick crack propagation is what brings about an abrupt, complete failing.

Unlike in ductile materials , there’s really little plastic deformation at the tip of the crack to reduce it down or take in power . The power from the used stress is concentrated at the crack suggestion, causing the atomic bonds to damage and the fracture to breakthrough. This can occur with a sharp snapping noise as the power is launched. The failure of the product to warp and blunt the fracture idea is what makes it so susceptible to brittle fracture .

Surprisingly, yes, a generally ductile product can come to be much more fragile under certain conditions. This phenomenon is called embrittlement . Among the most usual factors that can make a product weak is temperature level. Many ductile products , including specific types of steel, will certainly become much more fragile at lower temperatures . This is an important consideration for materials made use of in chilly environments or cryogenic applications.

Various other elements can also cause embrittlement . For instance, exposure to particular chemicals can bring about what’s called hydrogen embrittlement . In time, adjustments in the material’s interior framework, or microstructure, can also reduce its ductility and enhance its brittleness . This is a tip that the mechanical buildings of a product are not constantly continuous and can be affected by ecological problems and loading conditions . A material is ductile under one set of scenarios, but that can alter.

It’s easy to perplex brittleness with a lack of strength, yet they are various concepts. A better comparison is in between brittleness and toughness . Toughness is a step of a material’s capacity to absorb power and deform plastically before fracturing. Basically, difficult products can take a hit without damaging. A brittle material , necessarily, has reduced toughness .

Consider it in this manner: a ceramic coffee cup is tough and strong, yet not very tough. A small decrease can smash it since it can’t take in power via contortion . A vehicle bumper, made of a plastic composite, is made for high toughness . It can soak up the energy of a low-speed influence by deforming, stopping much more significant damage. The resistance to crack propagation is a key facet of toughness , a home that is gauged by its fracture toughness . A product with high fracture toughness is a lot more immune to brittle fracture.

Among the interesting mechanical residential properties of many brittle products is that they act extremely differently under pressing and pulling pressures. They commonly have a really high compressive stamina however a much lower tensile strength . This implies they can stand up to a lot of pressing ( compressive stress ) however will fracture easily when rived ( tensile stress ).

Concrete is an excellent instance. It’s extremely solid in compression, which is why it’s used for structures and assistance columns. Nevertheless, its low tensile strength suggests it will break conveniently if you attempt to stretch it. This inconsistency exists due to the fact that compressive pressures often tend to close the tiny fractures and defects that are present in the product, avoiding them from growing. Under tensile tons, these exact same defects are drawn open, resulting in a brittle fracture . This is a basic element of the basic residential or commercial properties of building products.