Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Two of the most famous metal alloys, brass and bronze, often get mixed up. At first look, they might seem the same, both shining with a golden color. But any expert will tell you that the difference between brass and bronze is huge. This article is for anyone who wants to know what really makes these two basic materials different. We will look into what they’re made of, check out their special qualities, and find out why picking the right one is so important for a project. I’m giving you the simple, straightforward guide I needed years ago, a close look at the world of brass and bronze.

First things first: brass and bronze are two of the most important alloys of copper people know about. I’ve always thought it was cool that by just mixing a few key things, we can make materials with much better qualities than the separate parts. That’s the great thing about an alloy. Basically, both brass and bronze start with the same main ingredient: copper. They are basically copper-based alloys, which gives them some things in common, like a good level of corrosion resistance and a nice variety of reddish and golden colors.

But this is where they become different. The story of brass vs. bronze is like copper having different partners. Imagine copper is the main dancer, and the element it joins with decides how the dance goes. This basic difference in what they’re made of causes all the other differences in how they act, from their hardness and durability to their price and how they handle their surroundings. Knowing this main difference is the first step to understanding the special jobs these metals do in everything from a simple fitting to a large sculpture. These aren’t just metals; they are materials with a past, each with its own story of how it was made and used.

Simply put, the main difference between brass and bronze is the main element they are mixed with. Brass is an alloy made mostly of copper and zinc. The amount of zinc content can change, which creates many different brass alloys, each with its own set of unique properties. For example, adding more zinc makes the metal stronger but harder to stretch. You might also find small amounts of other elements like lead, arsenic, or aluminum added to make it better for certain things, like being easier to cut or having better corrosion resistance.

On the other hand, the traditional partner for copper in bronze is tin. So, old-style bronze is composed of copper and tin. Like brass, there are many kinds of bronze alloys. Newer types of bronze often have other elements like aluminum, manganese, silicon, or even phosphorus to improve certain features. For instance, phosphor bronze is valued because it doesn’t get tired easily and has good wear resistance, making it ideal for things like springs and bearings. The main point here is simple: if you have a copper alloy, ask, “Is the other main element zinc or tin?” That will tell you if it’s brass or bronze.

I’ve always liked bronze for its history and pure toughness. One of the key properties of bronze is its great hardness and how it can bend without breaking. It’s a tough metal, but it’s not the kind that snaps easily. This mix makes it very long-lasting. Another important feature is its fairly low metal-to-metal friction. This is why you see bronze used a lot for things like bushings, bearings, and even a ship’s propeller. The material can handle a lot of stress and gets less damaged when it rubs against another metal.

Also, bronze is also known for its excellent corrosion resistance. It handles saltwater and many chemicals much better than other metals. When bronze reacts with air, it grows a nice protective layer called a patina, which stops it from rotting further. This is why old bronze items are still around today. Bronze’s resistance to corrosion makes it a trustworthy choice for boat parts and things that go underwater. Lastly, bronze also has a higher melting point than brass, which can be very important in some high-heat uses.

Now, let’s discuss brass. While bronze has its good points, there are many times when brass is the clear winner. The first thing I think of is how great it is for workability and machinability. Brass is more malleable and simpler to handle than bronze. It has a lower melting point than bronze, which makes it easier to pour into molds and shape into tricky forms. This ease of making things is a big advantage, often making brass items cheaper to make. If you need to make something with fine details, from a fancy lamp to a precise valve fitting, it’s often easier with brass.

Another big plus for brass is its great electrical conductivity. It’s not as good as pure copper, but it’s much better than most steel alloys and bronze. This quality, along with its good corrosion resistance, makes it a perfect material for electrical connectors, terminals, and other electrical applications. You’ll see it in everything from light sockets to the pins on your plugs. Its natural workability also means it’s a great material for sheet metal work, as it can be easily rolled, pressed, and shaped.

I’ve mentioned corrosion, but it’s good to look closer at how these two alloys deal with it because it’s a very important point. When it comes to handling the weather, especially saltwater, bronze usually wins. The tin in it helps it create a very strong protective oxide layer, or patina, which protects the metal underneath. This is why it’s the top material for boat parts.

Brass is also quite resistant to corrosion, which is why it’s so common in plumbing applications—it doesn’t rust like iron. But, brass can have a special corrosion problem called dezincification when it’s in water with a lot of chlorine. This problem pulls the zinc out of the alloy, leaving behind a weak, sponge-like copper structure. Even though many new brass and bronze mixes have elements to stop this, it’s a key difference between brass and bronze to think about for any project that will always be in water. Usually, the more zinc content, the more at risk brass can be.

This is where the talk changes from just being useful to looks and sounds. For decorative projects, the choice is often about color. Brass usually has a brighter, stronger gold color, a sunny yellow hue that many people like. It can be polished to a bright shine, making it ideal for fixtures, doorknobs, and trim. Brass tends to look more modern and bright.

In the world of musical instruments, though, it’s a more complicated story. Brass is known for its use in the brass section of an orchestra. Instruments like the trumpet, French horn, saxophone, and tuba are made from different types of brass. The reason is that the brass to make these instruments has great sound qualities; it’s easy to shape into the needed complex curves, and the metal alloy vibrates nicely to make clear, bright sounds. But bronze is used too. It’s the chosen material for making top-quality cymbals and some kinds of bells and guitar strings. The slightly different weight and hardness of bronze make a different sound, one that is deeper, warmer, and often richer and can last longer.

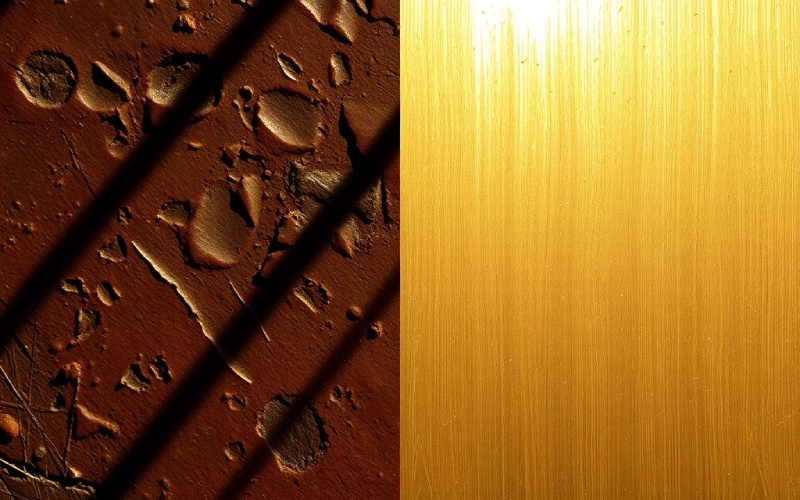

For someone without training, telling brass or bronze apart can be hard, but there are hints. The clearest one is color. Brass usually has a more yellow, sunny hue, like gold. Bronze, on the other hand, usually has a reddish-brown color. It often looks duller and not as bright as polished brass. If you see a metal with a clear reddish color, it’s probably bronze.

But, color isn’t a perfect test. There are many different metal alloys of both brass and bronze, with colors that can look the same. For example, some kinds of building bronze can look a lot like certain brasses. A better test, though not always easy, is to check the material’s surface for any marks. Often, a fitting or piece of hardware will have codes stamped on it that can help you find out the specific alloy. Seeing a greenish patina is also a big sign of bronze, though brass will also get darker over time, usually becoming darker and less shiny.

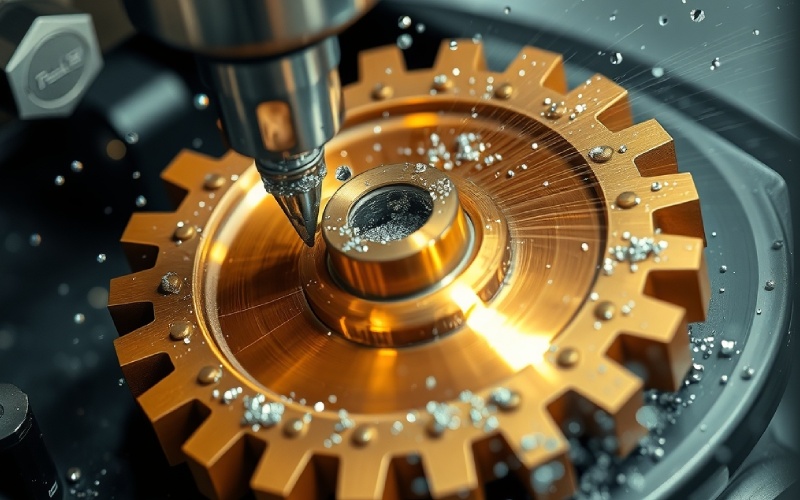

Besides being used for decoration and music, brass and bronze are very important materials in factories. Bronze’s mix of wear resistance, durability, and low friction makes it the best choice for bearings, bushings, and gears. Think about heavy machines where parts are always moving against each other. A bronze bearing can handle the force and lessen friction, making the machine last longer. Its resistance to corrosion also makes it vital for boat propellers and parts that are underwater.

Brass, with its great workability and machinability, is a star in making things. It’s used a lot for plumbing fittings—think of every valve, tap, and pipe connector in your house. These parts need to be corrosion-resistant, easy to make in large numbers, and dependable, and brass does all of that. Its electrical conductivity also makes it a key player in electrical applications. From simple screws and bolts to complex electrical connectors, brass is used because it gives a good connection without easily corroding. These properties that make each metal special decide their factory roles perfectly.

When you plan a project, how easy a material is to work with can be just as important as its final qualities. This is where the brass vs. bronze discussion becomes very real. Brass is also known for its better formability. The fact that brass is more malleable than bronze means it can be bent, pressed, and shaped with less work and power. This is a huge benefit in making things like with laser cutting or when creating detailed sheet metal designs. Its lower melting point also makes the casting process simpler.

Bronze, being a harder and often more brittle material, needs more power to be worked on. Cutting bronze can be harder and may cause more damage to tools. While its hardness is a benefit in its final use (like a bushing or bearing), it can be a problem when making it. So, if your project has a lot of difficult shaping or needs to be made in large numbers, the better workability of brass might make it the smarter and cheaper choice. You have to weigh the needs of the final item with the real-world facts of making it.

So, after all this, how do you pick the right material for your next project? The choice between brass or bronze depends on three main things: what you’re using it for, the environment, and your budget. You need to ask yourself some questions. What qualities are most important? Do you need great hardness and wear resistance for a factory part like a bearing? If yes, bronze is the clear choice. Do you need great electrical conductivity for a wiring part or amazing workability for a detailed decorative item? Then you should probably choose brass.

Think about the environment. Will the part be in saltwater or around strong chemicals? Bronze’s strong corrosion resistance makes it the safer option. Is it for standard plumbing applications in a house? Brass has a long history of working well here. Lastly, think about price. Usually, brass is cheaper than bronze, mostly because zinc costs less than tin. For big projects, this price difference can be very important. By thinking carefully about these things—what it needs to do, where it will be, and how much it costs—you can surely choose the alloy that is perfect for what you need.