Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Have you ever wondered how a new car is designed? Or how people who build things draw the plans for a giant skyscraper? They do not just use a pencil and paper anymore. They use a special tool on the computer called CAD. This article is for you if you have ever been curious about how this works. I am going to explain CAD modeling using simple, easy-to-understand ideas. You will learn what it is and why it is so important for any engineer or designer. You will also see how it turns an idea into a real object you can hold. We will look at the amazing world of 3D CAD and how it builds our world. This guide will make the big world of design feel easy.

Let me ask you a question. Have you ever built something with toy blocks? You take simple pieces and put them together to make something new. In many ways, that is what CAD modeling is like. But you use a computer and special software instead of plastic blocks. The letters CAD stand for Computer-Aided Design. That is just a fancy way of saying “designing things with help from a computer.”

The whole idea of design felt very big. But really, CAD is just a tool. It helps people like an engineer or a designer to draft and build things on a computer screen. You can make a design for almost any object you can think of. This could be a new toy, a part for a car, or even a whole house. This cool tool is used in almost every kind of business today. The design you make is a perfect digital copy. Using this software, you can create digital versions of almost any object.

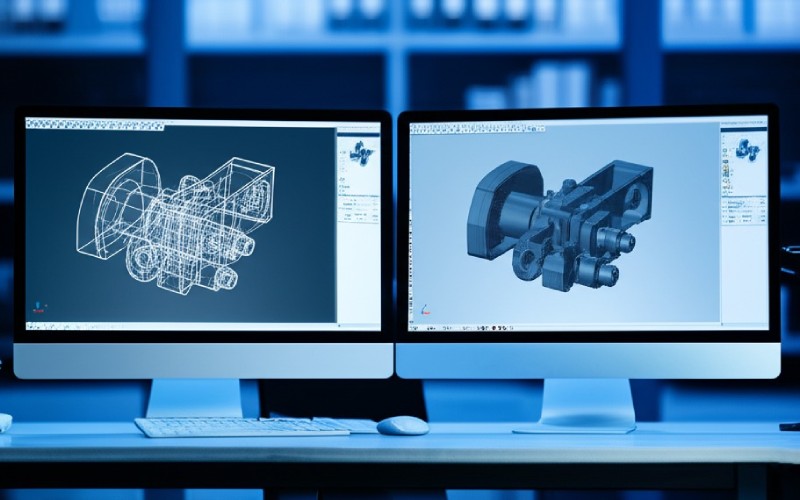

This way of working lets designers and engineers create digital models of parts. It also lets them see how the parts fit together. Before CAD, people had to make many drawings by hand. If they made one mistake, they had to start the drawing all over again. With CAD modeling, you can fix mistakes with one click. This makes the whole design job much faster and much better. It is a very important part of making new products today.

A person whose job is to be an engineer or designer needs their work to be perfect. Think about an architect who is designing a bridge. The measurements must be exactly right. A small mistake could cause a very big problem. This is where CAD modeling helps. It lets you be very, very exact with your design.

For a designer, CAD is a way to make ideas real. Let’s say a person who designs products has an idea for a new phone. They can use 3D CAD software to build a 3D model of it on the computer. They can look at it from every angle. They can see how it might feel in a hand. And they can make changes very easily. This helps them make the design perfect long before they spend money making it for real. It helps them make a better design right from the start.

Engineers and designers use this software to test their ideas. They can see how the parts of a machine will fit together in an assembly. An assembly is when all the parts are put together. They can even run a computer test, called a simulation, to see if a part is strong enough. This power to test and check a design on the computer saves a lot of time and money.

I am often asked, “Why is this software so special?” The best thing about it is how much it helps the design workflow. A workflow is all the steps you take to do a job. It gives a designer so much freedom to make changes. If you draw something on paper and want to change it, you have to erase and draw it again. With CAD, you can change a shape, color, or size in just a few seconds. This freedom to try new things leads to a better design.

Here are some of the main good things about it:

This power to simulate is a huge advantage. Before, an engineer had to build a real prototype to test their design. This cost a lot of money and took a lot of time. Now, a computer test can tell them if their design will work. This helps them find problems early on in the product design journey. How much faster it makes any design job is amazing.

Yes, there is more than one type of CAD. When I first started, most of my work was in 2D. Think of 2D CAD like a smart piece of digital paper. You can draw flat shapes like a rectangle, a circle, or a line. It is used to make flat drawings, like a floor plan for a house or a blueprint for a machine part. These are often called technical drawings.

But today, most of the excitement is about 3D CAD. With 3D CAD, you do not just draw a flat shape. You create a full, solid object on your computer. You can turn it around and look at it from any angle. It is just like you are holding the object in your hand. This is the kind of CAD most people mean when they talk about CAD modeling. It gives you a much better feel for the final design.

Going from 2D to 3D CAD changed everything for me. I used to have to imagine what a flat drawing would look like in real life. Now, I can see the 3d design right there on my screen. This is very helpful for every person on the team, from the designer to the person who will build it. It makes a tricky design much easier to understand.

When you work with 3D CAD, you will often hear the name solid modeling. This is one of the most popular ways to create a 3D design. You can think of it like working with digital clay. You start with a simple shape. Then you add to it or cut pieces away from it. For example, you might draw a 2D circle. Then you can use a tool to extrude it. That means pulling it up to make a cylinder.

The word “solid” in solid modeling is important. It means the computer understands your object is a solid thing. It knows the object has an inside and an outside. It can even figure out how much it weighs if you tell it what it is made of. This is very helpful for an engineer doing mechanical design. They need to know things about a part for it to work right when all the machine parts are put together.

This type of 3D modeling uses something we call parametric design. This is a very important idea. It means the shape is made using numbers, or a parameter. If you want to make a hole bigger, you do not just stretch it. You change the number for its size from 1 inch to 1.2 inches. The software then fixes the design all by itself. This lets you be in charge and make everything perfect. Programs like SolidWorks are very good at this.

Now, let’s talk about another kind of 3D modeling. It is called surface modeling. If solid modeling is like building with clay, surface modeling is like stretching a digital skin over a wire frame. The object you make has no inside. It is just a very thin surface. This method is all about making the outside look and shape of a design.

So, why would you want to use this? Surface modeling gives a designer a lot of freedom. It helps them create tricky shapes and shapes that look like they came from nature. These are sometimes called organic shapes. Think about the smooth, flowing curves of a sports car. Or think about the handle of a new kitchen tool. These shapes are very hard to make with solid modeling. Surface modeling lets a designer push and pull on the surface to get the exact look they want.

This way of working gives you a lot of freedom for your design. It is used a lot in the car industry and for product design where the look of the item is very important. The goal is to make a perfect outer surface. Later, an engineer might take that beautiful surface design. They can then work to build the solid parts that go inside it. It lets you change the surface of an object with a lot of control.

Yes, you can! This is one of the most fun parts of modern 3D CAD. Some software now has tools that work just like a real artist’s tools. This is often called freeform modeling. You can push, pull, smooth, and sculpt a digital object. It is a very hands-on way to design.

This method lets a designer create digital models that look and feel very natural. Artists use this to sculpt characters for movies and video games. Product designers use it to sculpt handles that are easy to hold or special new furniture. It breaks free from the straight lines and angles you sometimes see in other kinds of CAD modeling. You can truly sculpt your idea.

This shows how much CAD software has grown. It is not just a tool for an engineer anymore. It is also a powerful modeling tool for artists and any creative designer. The power to sculpt a design opens up a whole new world of things you can do.

There are many different CAD programs out there. Some are made for a certain kind of work, while others can be used for anything. If you are excited to start, it can be hard to know which one to pick. Let me share a few of the big names that I have used.

| Software Name | What It’s Used For | Who It’s Best For |

|---|---|---|

| Autodesk AutoCAD | Making flat drawings, plans for buildings, and engineering plans. | An expert who needs perfect flat drawings. |

| SolidWorks | Making 3D parts for machines, solid modeling, and testing. | An engineer who makes parts for machines and puts them together. |

| Autodesk Fusion 360 | A tool that helps you design, test, and get ready for making things. | A designer who wants to design and test their ideas. |

| SketchUp | 3D modeling, designs for buildings, and designs for the inside of houses. | Beginners, an architect, and people who work with wood. |

Autodesk is a very big company in this industry. Their AutoCAD software is famous for 2D drawing. SolidWorks is a favorite for many people who do mechanical design. For people just starting, I often suggest SketchUp. It is easier to learn and is a great way to get started with 3D modeling. Each program is good for a different kind of design job.

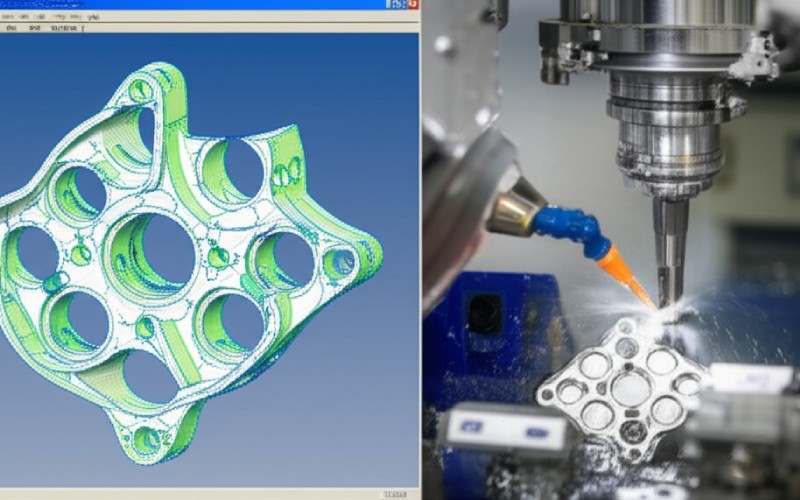

Making a beautiful design on a computer is great. But how does it become a real object? This is where CAD files help. When you finish your design, you save it as a special file. Two common types are STL and OBJ. These files hold all the information about your object’s shape and size.

You then send these cad files to a manufacturer. Their machines can read the file. They use it as a set of instructions to build the object. For example, with a 3D printing process, the printer reads the file. Then it builds the object one layer at a time. This way of doing things is called rapid prototyping. It lets a designer get a real prototype of their design in just a few hours.

This strong connection between the digital design and the real-world manufacturing is very powerful. It makes the trip from an idea to a product much shorter. An engineer can design a part, make a prototype with a 3D printer, test it, and then make changes to the design all in the same day. This helps people come up with new ideas faster in every industry. This digital way of working is very important for making things today.

If all this sounds exciting, you might be wondering how you can start. The good news is that it is easier now than it has ever been. You do not have to be an expert engineer to learn. Many great CAD programs have free versions for students and people who do it for fun.

My advice is to start with something simple. Pick an easy-to-use software like SketchUp. You can find thousands of free lessons online. Start by learning to make simple shapes. Design a table. Design a cup. When you feel more comfortable, you can try harder projects. The most important thing is to practice and have fun with the design work.

Do not be afraid to try new things. The wonderful thing about CAD modeling is that you can always “undo” a mistake. You can try an idea, and if it does not work, you just go back a step. It is a way to learn the main ideas of design and 3D modeling without any risk. With a little time, you will be amazed at what you can make.

To finish up, here are the most important points I hope you remember: