Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

This article teaches you how to figure out the machining time for any job on a CNC machine. When you know the machining time, it helps you set prices for jobs and schedule your work. Read this to learn easy formulas to get a close idea of the time for any machining operation on your machine. This guide is helpful for anyone in a machine shop who estimates job times or runs a machine.

Knowing the machining time for an operation is really important. It is the first thing you do to figure out the cost of making a part. If your guess about the time is not right, you might lose money. A good machining time calculation helps you set a fair price for your work. It also helps you schedule jobs for every machine in the workshop. This kind of planning helps you work faster and better.

A good calculation also helps you find ways to do the job quicker. Maybe a different cutting tool or a faster machine could do the work in less time. This helps your whole business make more money. Every machine has a cost for each hour it runs. The machining time tells you how much of that cost goes into making one part. This is a very important piece of the manufacturing process. Knowing this about your machine is a must.

Many things can affect how long a cutting job takes. Before you figure out the time, you need to know about these things. The biggest factor is the kind of machine you are using. A mill machine is not the same as a lathe machine. The kind of material you are cutting is also a big deal. Cutting steel is a slower process than cutting aluminum. The machine has to work with more force.

You also must know about the cutting tool. What is the tool made of? How many cutting edges does it have? The part’s plan, or drawing, shows you the size and shape you must create. This means you need to know the length of the cut, the diameter of the part, and the depth of the cut. Last, the settings on the machine are important. These settings are the cutting speed and the feed rate. A good person running the machine knows how to choose the best settings for that machine and cutting tool.

RPM stands for revolutions per minute. It tells you how many times the machine’s spindle spins in one minute. The spindle is the part that holds the workpiece on a lathe machine or the cutting tool on a mill machine. Figuring out the correct RPM is step one in any machining time calculation. You use a formula to find the RPM. The formula is a little different if you are using metric units (mm) or imperial units (inches).

The formula for RPM uses the surface speed (SFM) of the material. Surface speed is a measure of how fast the tool moves over the material’s surface. You can find suggested speeds for every material in a special handbook. The other piece of information you need for the formula is the diameter of the part you are cutting or the diameter of the tool.

Here are the formulas to find RPM:

| Unit System | RPM Formula | Description of Terms |

|---|---|---|

| Imperial (Inches) | RPM = (SFM * 3.82) / Diameter | SFM: Surface Feet per Minute. Diameter: Diameter of the workpiece or tool in inches. |

| Metric (mm) | RPM = (Surface Speed 1000) / (3.14 Diameter) | Surface Speed: Cutting speed in meters per minute. Diameter: Diameter of the workpiece or tool in mm. |

Getting the RPM right is very important for doing a good job. A machine that is running too fast might break a tool. A machine that is running too slow is a waste of time. This simple formula is the beginning of any good guess about the time it will take. The machine needs to run at the right number of revolutions per minute.

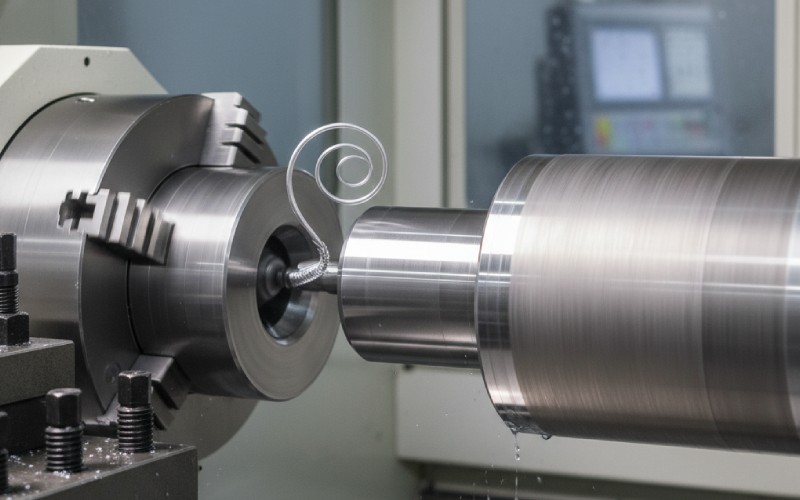

Turning is a machining operation that is done on a lathe machine. The workpiece spins around, and a cutting tool with a single point travels next to it to cut material away. To find the machining time for one trip of the cutting tool, you need to use a simple formula. This calculation is used for jobs like facing or making a diameter smaller on a part.

The basic turning formula is:

Machining Time (T) = Length (L) / (Feed Rate (f) * RPM (N))

In this formula, L is the total distance the tool travels, in inches or mm. This includes the length of the part and a little extra room for the tool to get to the part and move away from it. N is the RPM, or revolutions per minute, that we figured out before. f is the feed rate. The feed rate is the distance the tool travels for every one full spin of the part. It is often written as inches per revolution (IPR) or mm per revolution. The correct feed rate to use depends on the tool, the material, and if you are doing a rough cut or a finish cut. A rough cut will use a faster feed rate.

Yes, let’s look at an example of a cnc turning operation. Let’s say you need to cut down the outside of an aluminum rod to a certain size. The machine you will use is a normal CNC lathe. The part drawing gives us the details we need.

Here is the information for our example operation:

First, we use the formula for RPM:

Next, we use the formula for turning machining time:

This calculation is for a single, perfect cutting trip. But in the real world, a machine is not perfect. We use something called an efficiency factor. In this case, that factor is 0.85. So, the real time is 0.2908 / 0.85 = 0.342 minutes. This time is for one single pass. If a job needs the tool to go back and forth many times to get to the final diameter, you must multiply this time by how many passes are needed. For example, if the tool cuts away material in three separate passes, the total cutting time for this machine operation is 3 * 0.342 minutes. This is a very helpful way to figure out the time.

A mill operation is not the same as a turning operation. In milling operations, the cutting tool spins, and the part you are working on stays in one place on the machine’s table. The table then moves the part into the tool that is spinning. A tool for a mill can have a lot of sharp edges for cutting. These are sometimes called teeth or flutes. A mill machine is able to make flat surfaces, grooves, and pockets.

The important thing to know for a mill is the feed per tooth. This is the amount of material that each cutting edge, or tooth, cuts away with each spin. This is not like a lathe, which uses a tool with one point and a feed rate in inches per revolution (IPR). On a mill machine, the feed rate is normally given in inches per minute (IPM). To find the IPM, you need to know the feed per tooth, how many teeth are on the tool, and the RPM of the machine spindle. This is the biggest difference when you figure out the time.

The formula to find the machining time for a mill operation is also easy to use. It looks a lot like the turning formula, but we use the feed rate in another way. The machine must be set up the right way to make sure your time calculation is right.

The formula for mill machining time is:

Machining Time (T) = Distance (L) / Feed Rate (IPM)

In this formula, L is the total motion distance the tool travels over the part, in inches or mm. The feed rate IPM is given in inches per minute. But you often have to find the IPM first. Here is the formula for that:

IPM = RPM Feed Per Tooth Number of Teeth

Let’s imagine a mill tool with 4 teeth is spinning at 800 RPM. The feed per tooth is 0.005 inches.

Drilling a hole is another very common machining operation. A drill is a kind of tool that has two cutting edges, which are called flutes. The calculation to find the time it takes to drill a hole is a lot like the calculation for turning. You must know the depth of the hole, the RPM of the drill, and the feed rate for the drill tool.

The formula for the time to drill a hole is:

Time to Drill (T) = Hole Depth (L) / (Feed Rate (IPR) * RPM)

In this formula, L is the depth of the hole you want to drill. People often add a little extra to the depth so the point of the drill can come out the other side of the material. The Feed Rate is once again in inches per revolution (IPR). The RPM is the revolutions per minute of the drill tool in the machine’s spindle. For example, if you must drill a hole that is 2 inches deep with a tool at 1000 RPM and a feed of 0.005 IPR, the calculation is not hard. The time would be 2 / (0.005 * 1000) = 0.4 minutes. For a diameter hole of a certain size, you have to use the right drill tool. A bore operation might be needed to make the hole extra precise. That operation also needs its own time calculation.

The cutting time is just one piece of the total machining time. A complete cnc machining programme is made of many steps. The total time to make a part is a lot longer than just the time the tool is busy cutting. You have to remember to include time for everything else that the machine does.

Here are some other things to add to your time guess:

A good person who estimates time knows to add these times to the cutting time to find the real total time for the operation. For example, a single cutting operation might take 0.12143 minutes, but the total time including a tool change could be much more. This makes your final time guess more correct.

Yes, there are simpler ways to get a good idea of the time. Many businesses use special computer software. This software can look at a part drawing and figure out the machining time for you. It already has the machine, tool, and material information. It builds a full cnc machining programme and gives you a very correct time. This is a lot quicker than figuring it out yourself with a calculator.

Another helpful tool is a machining time calculator. This could be a small program or a spreadsheet file. You type in the numbers, like diameter, length, RPM, and feed rate, and the calculator will give you the time. This is a great way to quickly figure out the time. But, doing the calculation by hand helps you learn how everything works. It helps you see how each different number affects the total time and cost. Understanding the formula is a great skill for any person in the world of cnc machining. The person running the machine often gets a good sense of how long a job should take just from experience.

Here is a short list of the most important things for figuring out machining time: