Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for high-precision parts that can withstand extreme heat, harsh chemicals, and heavy wear? At Istar Machining, we’ve mastered the art and science of ceramic CNC machining. Our team turns tough ceramic materials into parts with amazing accuracy and smooth finishes.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

When you choose Istar Machining for your ceramic components, you get:

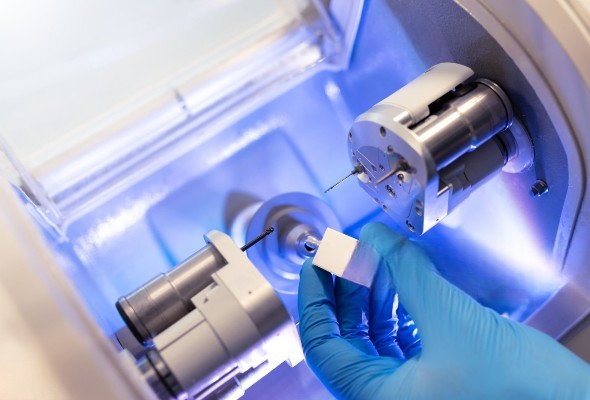

Our precision CNC machining shop uses 5-axis CNC milling, ultrasonic drilling, and diamond grinding to create parts that meet the most demanding specs.

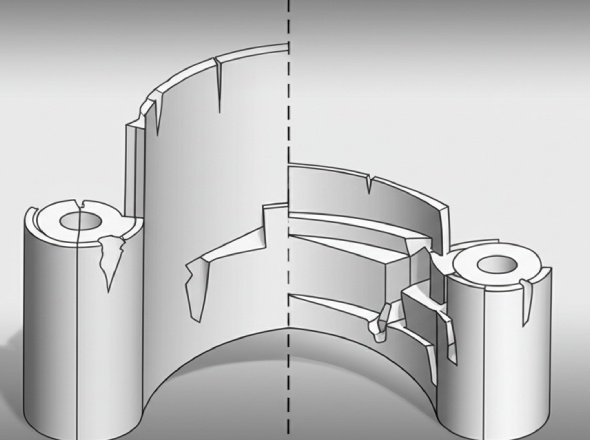

Our 5-axis machining capabilities allow us to transform these tough ceramics into precisely engineered parts:

Alumina is a top pick. It is:

Alumina is used for:

When you cut alumina, you need:

One big win was when alumina was used in computer part holders. It cut bad things by 30%!

Zirconia is very good for:

Zirconia is used for:

When you cut zirconia:

A dental shop made zirconia teeth with a 5-axis CNC milling machine and cut waste by 45%!

Silicon Carbide is best for:

Silicon Carbide is used for:

To cut Silicon Carbide:

The army used Silicon Carbide for armor and it was 20% lighter than steel but just as strong!

Silicon Nitride is good for:

Silicon Nitride is used for:

To cut Silicon Nitride:

Jet engines with Silicon Nitride blades last 15% longer than old ones!

Macor is special because:

Macor is used for:

When cutting Macor:

A light parts maker used Macor and made parts 50% faster!

CMCs are:

CMCs are used in:

Our ceramic CNC machining solutions serve these key industries:

Parameter | Capability | Applications |

Tolerance | ±0.005 mm | Precision bearings, semiconductor fixtures |

Surface Finish | Ra 0.1–1.6 µm | Optical components, sealing surfaces |

Min. Feature Size | 0.2 mm | Microfluidic channels, small holes |

Max. Part Size | 450 mm | Large insulators, structural components |

Thermal Resistance | Up to 1600°C | Furnace parts, engine components |

Typical Lead Time | 5–14 days (prototypes) | R&D projects, proof-of-concept models |

To get the best results and keep costs down:

We help optimize your designs for ceramic machining

Our 5-axis machines and diamond tooling ensure perfect results

We understand the unique properties of every ceramic type

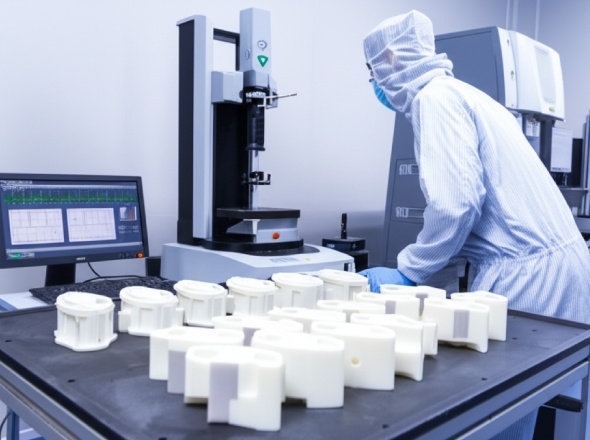

Rigorous testing ensures your parts meet specifications

Get quotes within 24 hours for your projects

We help you pick the best ceramic for your needs

Our engineers will work with you to make sure your design is ready for ceramic machining

Istar Machining uses specialized techniques for ceramic parts

Every ceramic part undergoes rigorous inspection

Ready to explore how ceramic CNC machining can improve your products? The team at Istar Machining is here to help with expert advice and fast quotes.

Contact us today to discuss your ceramic component needs and discover why leading companies trust Istar Machining for their most demanding applications.

Green-state machining works with unfired ceramic that’s softer and easier to cut. After machining, parts are fired to reach full hardness. This is often cheaper but has more size change during firing.

Fired-state machining works with already-hardened ceramic using diamond tools. This is more expensive but gives tighter tolerances.

Ceramics excel where metals fail:

Standard tolerances are ±0.005 mm, but we can achieve ±0.002 mm for critical features using our precision grinding services.

Yes! Our rapid CNC machining services can deliver ceramic prototypes in as little as 5-7 days.