Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

I have seen lots of different ways to keep metal safe. But one way is special. It has great benefits, and it is very good for aluminum. It’s called chem film. You might also hear it called a film coating or a conversion coating.

In this post, I will tell you about what I know. We will talk about what a chem film is. We will also talk about why it is a very big deal. I will tell you how the whole chem film process works. I will use easy words. This article is for you if you work with metal parts. It is especially for you if you work in the aerospace or electronics business. You will find out how this easy film coating can help you save time and money. It can also make the things you make a lot better.

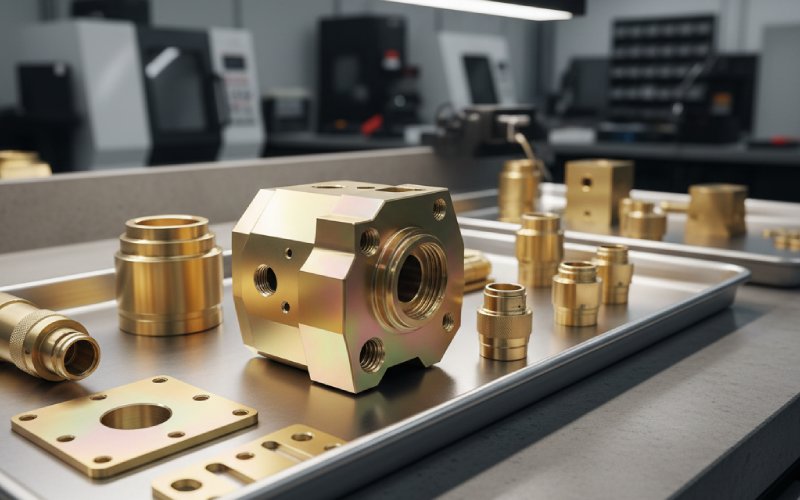

Let’s begin with the simple facts. What is a chem film? I can still recall the first time I saw a part that had this finish. It had a light, shiny gold color. It was not paint. And it was not plated. I learned it was a conversion coating. This means the chem film is not an extra layer that is added on top of the metal. Instead, it is a chemical process. This process actually changes the surface of the metal itself. This makes a new surface that helps protect the metal. The film coating truly becomes a part of the metal.

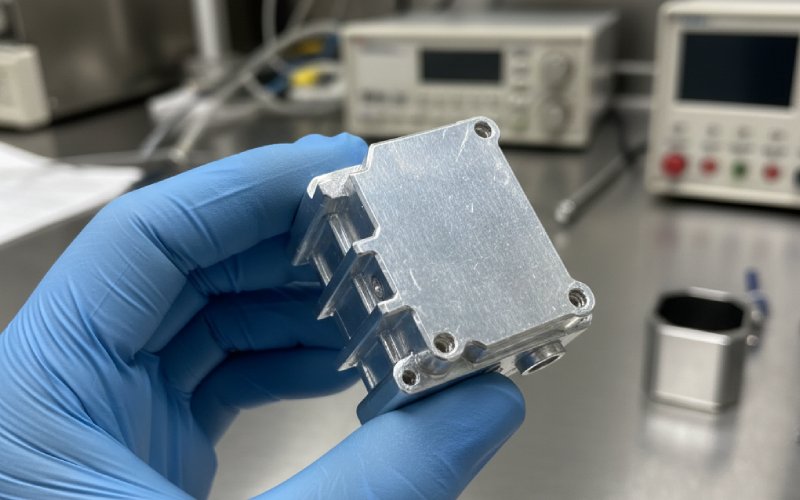

This process is often called by a brand name, like Alodine. The official name is a chromate conversion coating. The process uses a special chemical bath. This bath makes a very thin film on the surface. The most important job of this chem film is to protect the metal from the world around it. You can think of it like a shield. This shield is chemically attached to the part. This special film coating is extremely thin. Because of this, it does not change the size or shape of your parts. This is a very important point for work that needs to be exact. This is a very big advantage of a chem film.

The chemical film coating is a wonderful thing. It is a very good and low-cost way to protect a metal part. Because the chem film is so thin, it does not add any weight. This is a big reason why the aerospace industry loves it. Every ounce matters on an airplane. The film coating does its job without being heavy.

You might be asking, “Why should I care about this?” The benefits of chem film are very big. It does not matter what industry you work in. The number one reason is corrosion resistance. Parts that are made from aluminum or magnesium can get rusty or damaged. This happens a lot in wet or salty places. A chem film coating can stop that from happening. It makes a wall that keeps water and other corrosive things out. This helps parts last for a much longer time.

Another big benefit is that a chem film makes a great starting layer for paint. I will say more on this later. But it really helps paint hold on to the metal surface. The third big benefit is electrical conductivity. Some kinds of chem film allow electricity to go through the surface. This is very important in the electronics and aerospace fields. It lets you ground parts. At the same time, it still gives them protection against corrosion.

I have seen this chemical film coating used in so many places. It is used on everything from airplane bodies to computer cases. The film coating is a key part of making sure these products are safe and long-lasting. The chemical treatment is a simple step that makes it much more valuable. Any industry that uses lightweight metal parts can benefit from a chem film. It’s a very smart choice to improve the quality of your final product.

The chem film process is actually very easy. It is all about a chemical reaction that is carefully managed. To start, the metal part needs to be completely clean. Then, you dip the part into a special bath. This bath holds a chemical mix that has chromate compounds in it. The chemical in the bath works with the very top layer of the metal.

This reaction changes the metal surface. It becomes a thin, gel-like film coating. This new layer is now part of the metal. It is not something that can peel or chip off like paint. After the right amount of time, the part is removed from the bath. Then, it is given a rinse with clean water. This makes the chemical reaction stop. It also washes away any leftover chemical residue.

The result is a brand-new surface that is ready to do its job. It will protect the part from damage. The whole coating process is fast. It is much quicker than painting or plating. This makes it a great choice for making a lot of parts at once. The film process is a core part of modern metal finishing.

When you read a specification for a chem film, you will notice different types. The two most common are Type I and Type II. For a long time, Type I was the normal choice. It uses a chemical called hexavalent chromium. You might hear this called hex chrome. It makes a very strong and long-lasting film coating. It often has a yellow or gold color that you can see. It gives wonderful corrosion resistance.

But, there is one issue. Hexavalent chromium is not good for people or the environment. For this reason, the industry made a new choice: Type II. The Type II film coating uses trivalent chromium. This is a much safer chemical to work with. The trivalent chem film is most often clear. Sometimes it has a light blue color. It still gives good protection. But, sometimes it is not quite as strong as the older hex chrome version.

Many businesses, particularly in Europe, now only use Type II coatings. It is the modern, safer choice. The trivalent chromium compound is much better for everyone.

| Feature | Type I Chem Film | Type II Chem Film |

|---|---|---|

| Chemical Used | Hexavalent Chromium | Trivalent Chromium |

| Common Color | Yellow, Gold, Brown | Clear or Light Blue |

| Safety | Health concerns | Much safer |

| Performance | Excellent corrosion resistance | Good corrosion resistance |

Besides types, you will also see classes. The two main classes are Class 1A and Class 3. These classes tell you the main reason for using the film coating. Picking the right class is important for how your part will work.

Class 1A coatings are used for one main reason: protection. You use them when you need the very best corrosion resistance you can get. This type of coating makes a thicker protective layer that lasts a long time. This is what you would use for parts on the outside of a plane or a boat. The main idea is to keep the metal safe from the weather for the longest possible time. A Class 1A coatings is a workhorse.

Class 3 is different. Its most important job is to let electricity pass through easily. It also gives some protection. The Class 3 chem film coating is not as thick. This lets electrical current move through the surface without any trouble. This is very important for parts that must be grounded. It is also important for parts that are in an electrical circuit. You get good electrical conductivity. You also get okay corrosion protection. The specification for your project will tell you which class you need.

The most common type of metal for a chem film is aluminum. It works great on aluminum. It also works great on the many different kinds of aluminum alloy. The reason is that aluminum naturally makes a thin oxide film. The chemical solution can change this film very easily. You could say the chem film process was almost made just for aluminum.

But aluminum is not the only metal. You can also put a chem film coating on other metals that are light. It is possible to use these film coatings including on other metals. For example, magnesium parts are often given a chem film treatment. You can also use it on zinc and cadmium. Some special mixes can even be used on copper, titanium, or other metal surfaces.

The specific chemical mix in the bath might be different. It depends on the base metal (the substrate). A good metal finishing supplier will know the correct mix for each type of metal. They will change the chemical coating process to match the special alloying elements in your metal components. The goal is always the same. They want to make a perfect film coating to protect the part.

Yes, it is a very good primer! This is one of the biggest reasons people use a chem film. If you have ever tried to paint right onto a plain aluminum surface, you know it can be hard to do. The paint does not want to stick very well. It can peel or flake off very easily. This is a problem a chem film can fix.

The chem film makes a surface that is steady and a little bit rough. This gives the paint something to grab onto. It makes the adhesion much, much better. In truth, a chem film is one of the best primers to use for paint on aluminum. The paint will adhere better. It will also last for a longer time. The chem film coating works like a perfect base for the adhesive in paint.

I have seen tests. In the tests, they look at painted parts with a chem film and without one. The difference is like night and day. The part that has the chem film looks great for many years. The other part starts to have problems very fast. This is why the chem film is often used as a primer. It is a very important step to maintain a great finish on painted metal parts.

If you want a good chem film, you have to follow the steps in the right order. A good conversion coating process is all about getting things ready and being in control. I think of it as a recipe. If you miss a step, the final dish won’t be right.

Here are the main steps a good supplier will follow:

Every step is important. If you miss the cleaning step or the etch step, the chemical film coating will not be made the right way. It might look patchy. Or, it might not give very good protection.

You may not think about this much. But electrical conductivity is extremely important for a lot of products. In the world of electronics, parts of a machine need to be connected to the ground. This stops static from building up. It also stops other electrical problems. In the aerospace industry, different parts of an airplane must have the same electrical level. This is a safety issue.

A normal paint or a thick coating like anodizing works like an insulator. It blocks electricity. This can be a big problem. A Class 3 chem film fixes this problem. The film coating is extremely thin. This lets electricity move right through it. This means you can get both corrosion resistance and electrical conductivity. And you can get them in just one step.

This is a very big advantage. You are able to protect your metal surfaces. You do not have to lose their electrical features. This is the reason the chem film is so well-liked for things like cases for electronics and parts for aircraft. It does two jobs at once. For some anodized surfaces, a chem film is used to fix scratches. It also helps to maintain electrical contact. This makes a patch that is thin, protective, and lets electricity pass through.

Picking the right company for your metal finishing is very important. Not all film coating services are the same. When you look for a supplier, you should ask them some questions. First, ask about their experience. How long have they been putting on chem film coatings? Do they work with your industry?

Ask to look at their special papers, or certifications. A good supplier will be approved to meet certain rules. An example is the military specification (Mil-Spec). This proves they check their work carefully. Talk to them about their process. Do they clean and etch the parts the right way? What kind of chemical do they use? Do they offer both Type I and Type II?

Last, find a supplier who will work with you like a partner. They should be happy to talk with you about your work. They can help you pick the right type and class of chem film for what you need. When you work well together, it helps make sure you get a top-quality final product each time. Taking the time to find the right film coating services is a good idea.

Over my career, I’ve learned that a chem film is one of the most useful tools in metal finishing. It’s a simple, effective, and low-cost solution.

Here are the most important things to remember: