Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

What is chrome plating? How do you do it? And why it important? I wrote this article to give you the answers. It is my simple, clear guide to chrome plating that I am glad to share with you. I will show you everything, from the different kinds to how it is done. If you want to know how metal parts get that pretty, long-lasting shine, then this article is for you. This is the complete guide to chrome plating.

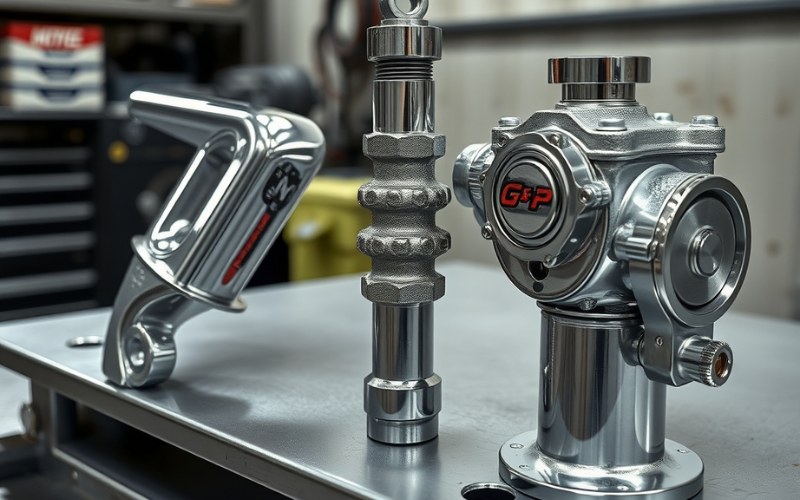

People often ask me this question first. To say it in a simple way, chrome plating is a process. It involves putting a layer of chromium on a metal object. You can think of it like a very thin and very strong metal jacket. The fancy name for this is electroplating a thin layer of chromium onto a metal object. But this is not just about making things look good. Chrome plating enhances an object in a lot of ways. It makes things very shiny. It also gives them great wear resistance and corrosion resistance.

Let me explain. Chrome plating offers a protective layer. This means the object below the chrome is kept safe. It is protected from rust, scratches, and everyday damage. This is why chrome plating is widely used. So, it could be a shiny bumper on an old car. Or it could be a busy part inside a machine. The goal is always the same. We want to make the object look nicer and last for a much longer time.

When people talk about chrome, they usually think of one thing. They think of that bright, mirror-like look. But I have learned that it’s good to know there are different types of chrome. For what we are talking about, we can talk about two main types of chrome plating. These are decorative and hard. These two are the most common kinds in the world of chromium plating.

The first kind is decorative chrome. This is the one you probably know the best. It is mostly for looks. It also gives a good amount of protection. The second kind is hard chrome plating. This one is not so much about looks. It is more about being strong and useful. Both decorative chrome and hard chrome are very helpful, but they are used for different things. Knowing the difference between chrome and hard chrome plating is very important. It helps you pick the right finish for your job. I have worked with both, and they each have a special job to do.

That is a very good question. The main difference between hard chrome and decorative chrome is about how thick it is and what it’s used for. Hard chrome plating is much thicker than decorative chrome. The difference in plating thickness is really big. This thickness is what gives hard chrome its amazing strength and wear resistance. It is sometimes called chrome or engineered chrome plating. This is because it is made to work very well.

On the other hand, the point of decorative chrome is to look beautiful and stop rust. The layer of chrome itself is super thin. The properties of the chrome layer for decorative chrome plating are all about getting a smooth, shiny finish that looks like a mirror. It also gives good corrosion resistance. But hard chrome plating is all about how it works. It makes a surface that things can slide on easily. It also makes it extremely hard.

To make this simpler, I made a table for you:

| Feature | Decorative Chrome | Hard Chrome Plating |

|---|---|---|

| Main Purpose | Appearance, Corrosion Resistance | Durability, Wear Resistance |

| Thickness | Very Thin (millionths of an inch) | Much Thicker (thousandths of an inch) |

| Undercoat | Always has a nickel undercoat | Put right on the metal |

| Appearance | Shiny, mirror-like, bluish tint | Dull, satin, or shiny gray |

| Main Benefit | Beautiful finish and rust protection | Makes parts last longer |

You can think of the chrome plating process like a science project. It’s one you can see and feel. It is a kind of electroplating process. To do it the right way, we use a special liquid bath. This is called a plating solution. This liquid has chromium mixed into it. It is usually in the form of chromic acid. Then, we put the object we want to plate, like a steel part, into this liquid.

The next thing we do is send electricity through the liquid. This electricity makes the little bits of chromium in the liquid attach to the object. It is a way of using electricity to move a thin layer of chromium onto a metal surface. This chrome electroplating method lets us decide how thick the chrome layers will be. It’s a really interesting process. It changes a normal metal object into something special with a lasting chrome coating.

Yes, I can. It might sound hard, but the basic plating processes can be explained in simple steps. Every step is very important. If you skip a step, the final look will not be good. The whole manufacturing process inside a plating facility is done very carefully.

First, the part has to be completely clean. The process begins with several steps for cleaning and washing. I must say this again: the surface can’t have any dirt, grease, or rust. Even a tiny piece of dirt will mess up the finish. The plating must be put onto a clean metal surface.

Here are the main steps that are part of the process:

Chrome plating involves being careful at every point. You cannot rush through it.

Decorative chrome plating is very popular for a big reason. It looks amazing. That bright, cool, shiny chrome look is really nice. This type of plating is used for aesthetic reasons more than anything else. It gives things a look and feel of high quality. The lovely chrome finish makes items look clean, new, and valuable. This is why decorative chrome is found on so many things, like bathroom faucets, cabinet handles, and parts for motorcycles.

But it is not just about how it looks. Decorative chrome plating is also a very good protector. It offers great corrosion resistance. The secret of decorative chrome is that it is usually not just chrome. A layer of nickel plating is put on first. This gives it most of its shine and protection from rust. The chrome layer on the very top is extremely thin. Actually, the chrome layer is so thin, you can almost see through it! This thin chrome layer stops the nickel from looking dull. It also gives it that light blue color that we know as chrome. A thin layer of chrome is all you need for a great look and good protection, especially on car parts. It is often used on car parts for this reason.

When we look away from shiny car trim and look at industry, that is where hard chrome plating is the star. This is sometimes also known as industrial chrome. The chrome applications here are all about working well. Because hard chrome plating adds amazing wear resistance, it is used on parts that are used a lot. Think about parts like hydraulic cylinders, pistons, and rollers inside a big machine. These parts are always moving and rubbing on each other. Without protection, they would wear out fast.

The purpose of hard chromium plating is to make the service life of a part longer. By putting on a thick, strong layer of chrome, parts can last many times longer. This saves businesses a lot of money on fixing things and buying new parts. Longer plating times are needed to build up this thick layer. Hard chrome plating makes a durable chrome surface. This is perfect for many industrial applications. Hard chromium plating is ideal for industrial applications that need a slippery surface and a lot of strength. It makes a thin dense chrome layer that can handle rough use and adds to the service life of the part.

This is a very serious subject in my line of work. Traditional chrome plating, which is called hexavalent chromium plating, makes use of chromic acid. This chemical, which has hexavalent chrome in it, works great but is very harmful. The waste from the process can hurt people and the world around us. Because of this, our industry has worked hard to find better and safer plating methods.

The best other choice we have now is called trivalent chromium plating. This method uses trivalent chrome. It is much less toxic than hexavalent chromium. The trivalent chromium plating process gives a look that is very close to the classic hexavalent chrome. It might not be as strong as standard hard chrome for some very tough industrial applications. But it is getting better and better. For decorative chrome, trivalent chrome is a wonderful and much safer choice. Many chrome plating services now give you this choice.

You cannot do chromium plating in your home. Chrome plating requires special tools and machines. The most important piece of equipment is the plating tank. This is a big tub that holds the plating liquid. The tanks must be made from special materials. These materials will not get hurt by the chemicals in the tank. In truth, the entire machine for this job is made to work with strong chemicals.

You also need a strong rectifier. This is the machine that gives the electricity for the electroplating process. It changes normal house power (AC) into the special DC power that plating uses. You also need racks or barrels. These hold the parts in the tank. Lastly, you need many tanks for cleaning and washing, along with systems for heating and fresh air. A good system makes sure the standard chrome plating is applied the right way and is safe. When the chrome is applied, every part of the system has to work as a team.

Sometimes, you have to take chrome off of a part. The old chrome plated layer might be broken. Or maybe you want to fix up an old part. The process to remove chrome plating is called stripping. It is like doing the plating process backward. Special chemicals are used. They wash away the chrome coating but do not hurt the metal underneath.

This must be done with great care. Different chemicals are used to take off different layers. For example, if you are stripping decorative chrome, you first take off the thin chrome layer. Then you take off the nickel layer. And then you take off the copper layer if there is one. After the old chromium plating is gone, the base metal parts can be polished. Then they are ready for a new coat. Chrome is known for being tough, so taking it off is a job for a professional.

I have given you a lot of information, so let’s finish with the most important ideas.