Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking to make round holes in metal or plastic? Circular pocket milling is a special way to cut clean, round pockets in your parts. Let’s learn how it works in simple words!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Circular pocket milling is when a machine uses a spinning cutting tool to make round holes in materials. Unlike regular drilling, this method can make wide, flat-bottomed holes with very smooth walls.

At Istar Machining, we use this method to create perfect round pockets in many materials like:

Circular pocket milling gives you many benefits over other cutting methods:

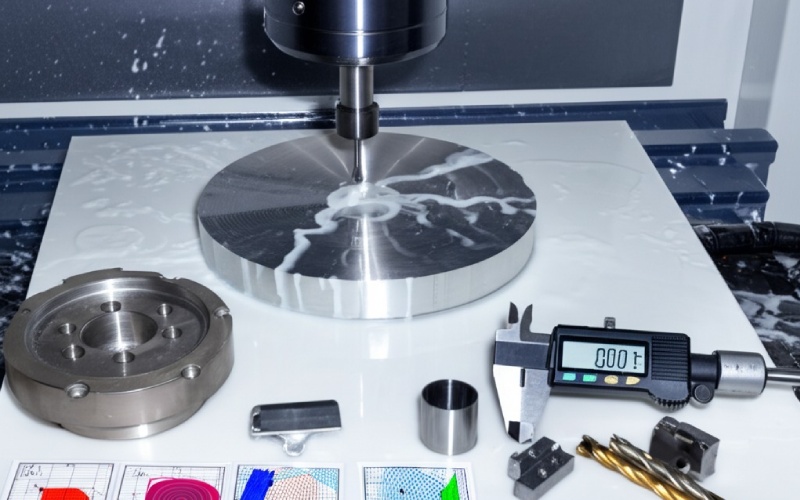

When we do CNC pocket milling for round holes, our machines follow these steps:

Here’s a helpful table showing tools and settings we use for different jobs:

Tool Size | Best For | Speed (RPM) | Material | Special Notes |

6-25 mm | Airplane parts | 8,000-24,000 | Titanium | Ball end mills for smooth corners |

10-20 mm | Car molds | 12,000-18,000 | Steel | Special coated tools last longer |

8-15 mm | Medical parts | 15,000-22,000 | Plastic | 30% stepover for smooth finish |

12-32 mm | Valve bodies | 10,000-16,000 | Stainless steel | Tools with coatings work twice as long |

6-12 mm | Electronics boxes | 20,000-24,000 | Aluminum | Feed rate: 0.2 mm per tooth |

Different materials are better for different jobs. Here’s what works best:

Metals

Aluminum (Common Grades: 6061, 7075, 5052, 2024) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

Stainless Steel (Common Grades: 303, 304, 316, 17-4 PH) offers excellent strength, high corrosion resistance, temperature resistance, and a hygienic surface finish.

Good for:

Why customers love it: “Its superior corrosion resistance and strength ensure parts last even in harsh environments, ideal for demanding applications.”

Mild Steel (e.g., 1018, A36) is a cost-effective ferrous metal known for its good machinability, weldability, and strength. It is ferromagnetic.

Good for:

Why customers love it: “It’s an affordable and easy-to-work-with material for general engineering purposes where corrosion resistance isn’t a primary concern.”

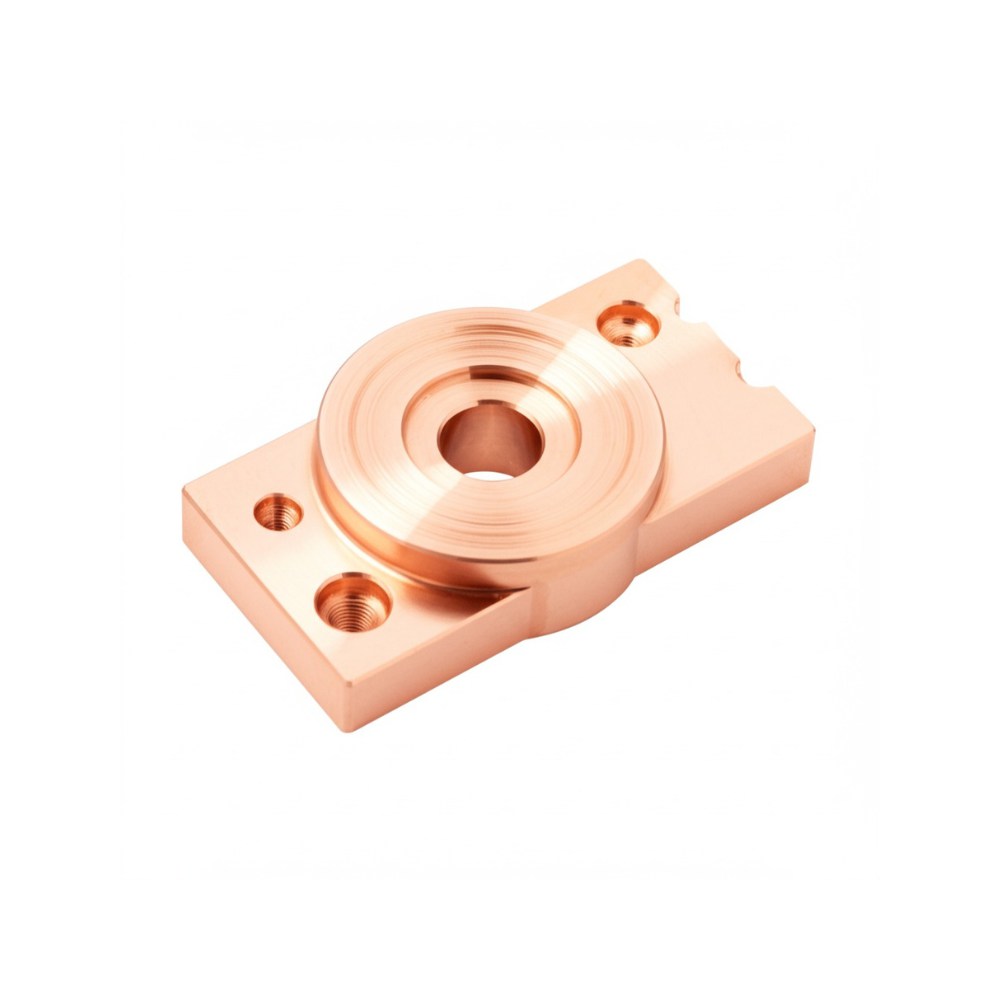

Brass (e.g., C360) is an alloy of copper and zinc known for its excellent machinability, good corrosion resistance, electrical conductivity, and aesthetic appearance.

Good for:

Why customers love it: “It’s one of the easiest metals to machine, allowing for fast production of intricate parts with good mechanical and electrical properties.”

Titanium (e.g., Grade 2, Grade 5/Ti-6Al-4V) is known for its high strength-to-weight ratio, excellent corrosion resistance (especially against saltwater and chemicals), and biocompatibility. Machining requires specific approaches due to its properties.

Good for:

Why customers love it: “Offers incredible strength and corrosion resistance at a low weight, perfect for high-performance and biocompatible applications where other metals fall short.”

Plastics

PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic with exceptional mechanical strength, high-temperature resistance, chemical inertness, and wear resistance.

Good for:

Why customers love it: “It maintains its strength and properties under extreme conditions – high heat, aggressive chemicals, and high mechanical stress.”

Delrin (Acetal / POM) (Polyoxymethylene) is an engineering thermoplastic known for its high stiffness, low friction, excellent dimensional stability, and good wear resistance.

Good for:

Why customers love it: “It machines beautifully to tight tolerances and offers great mechanical properties, low friction, and stability at a reasonable cost.”

Nylon (PA, Common Grades: 6, 6/6) is a versatile engineering thermoplastic known for its toughness, good wear resistance, and decent chemical resistance. It can absorb moisture, affecting dimensional stability.

Good for:

Why customers love it: “It’s a tough, abrasion-resistant, and cost-effective plastic suitable for many mechanical applications, especially involving friction or impact.”

Polycarbonate (PC) is a strong, impact-resistant, and transparent thermoplastic. It maintains rigidity over a wide temperature range.

Good for:

Why customers love it: “It provides exceptional impact strength and transparency, making it ideal for protective components and applications where visibility is key.”

Acrylic (PMMA / Polymethyl Methacrylate) is known for its excellent optical clarity, weather resistance, and rigidity. It’s more brittle than Polycarbonate but easier to polish to a high shine.

Good for:

Why customers love it: “Offers glass-like clarity and is easy to machine and polish, perfect for aesthetic applications and display purposes.”

People use circular pockets in many different parts:

When we make circular pockets, we check them carefully:

For the best results, our experts use these special methods:

When you need perfect circular pockets, our 5-axis machining center can help:

Our special methods cut time by 25%

Our workers know how to make perfect pockets

We use the best CNC machines from Germany and Japan

Every part is checked three times

Get high quality without high cost

If you need circular pockets in your parts, we’re ready to help! Our team can make your design come true with perfect round cavities in any material.

Get a free quote today! Just send us your drawings or 3D models, and we’ll show you how our CNC milling can make your parts perfect.

A: We can make pockets up to 10 times deeper than they are wide, depending on material.

A: We can make pockets as small as 1mm in diameter with special micro-tools.

A: We use special holders, slower speeds, and high-pressure coolant to stop vibration.

A: For aluminum, we use 0.1-0.3 mm per tooth with special coated tools.

A: Yes! Our machines can make walls at any angle from 0-90 degrees.

If you care more about appearance, corrosion margin and extrusion-friendly shapes, 6063-T52 usually wins. If you care more about structural

If you work in construction, fabrication, CNC machining, product design, or procurement, you’ve probably hit this exact moment: “The drawing

You almost never choose between a bearing and a bushing because of friction alone. You choose because of how you