Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

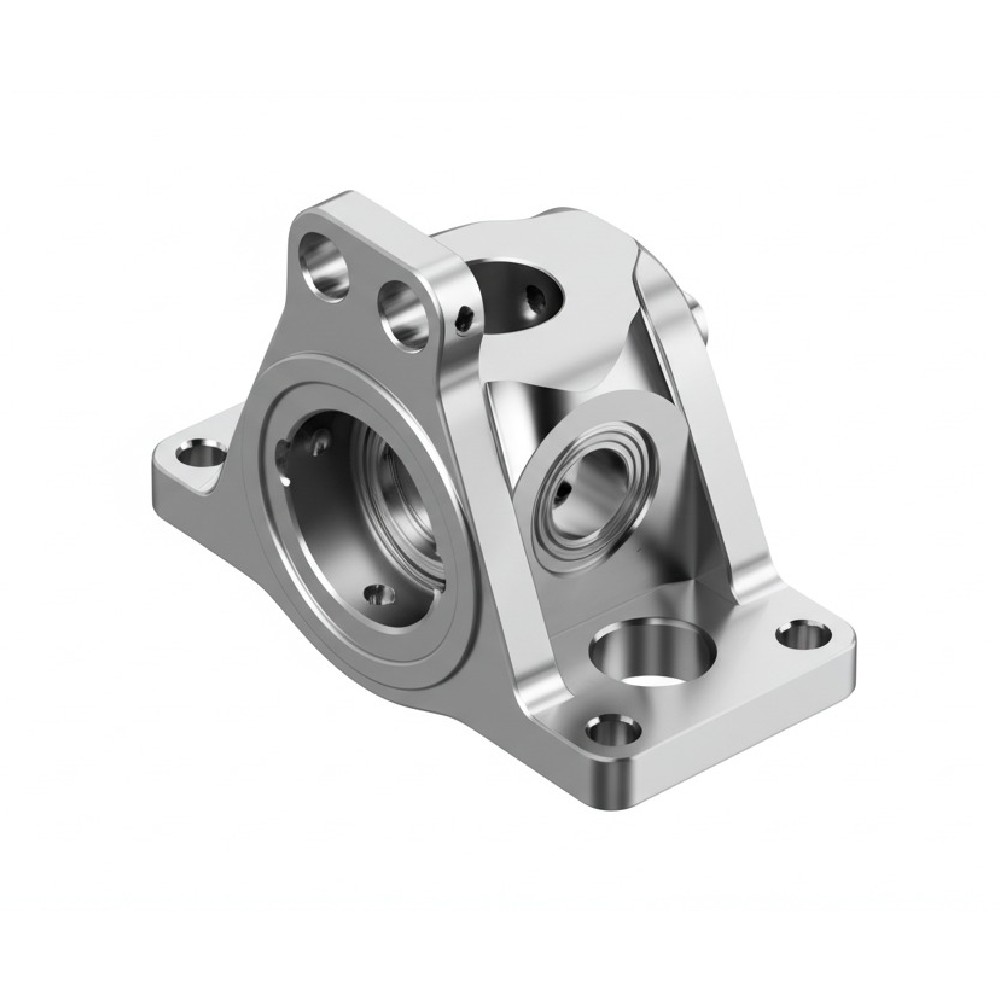

Alloy CNC machining is a modern way to make strong metal parts using computer-controlled machines. At Istar Machining, we cut and shape different metal alloys into exact shapes for many industries. Our machines follow computer designs to make parts that are super precise and perfect every time.

An alloy is a mix of metals that makes them stronger and better than just one metal alone. When we do CNC machining, we can work with many different alloys to match what you need your part to do.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

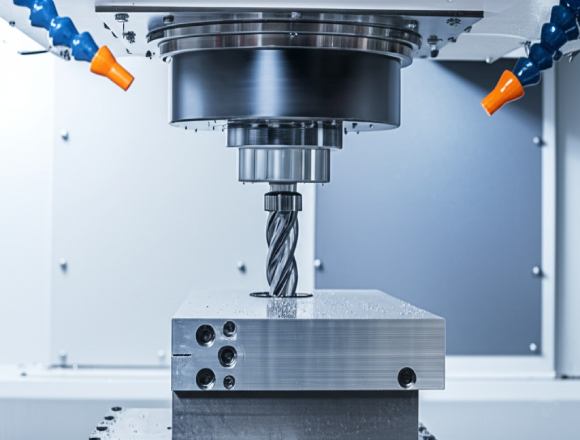

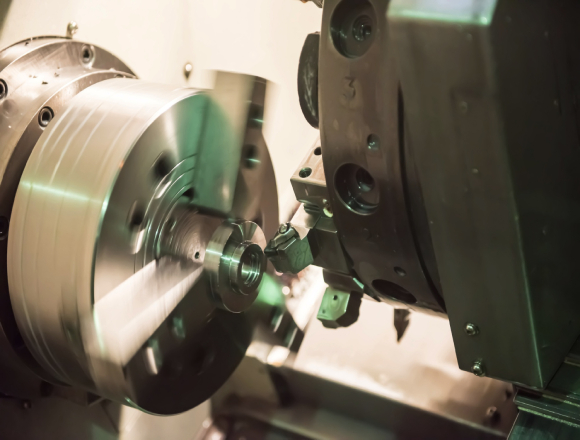

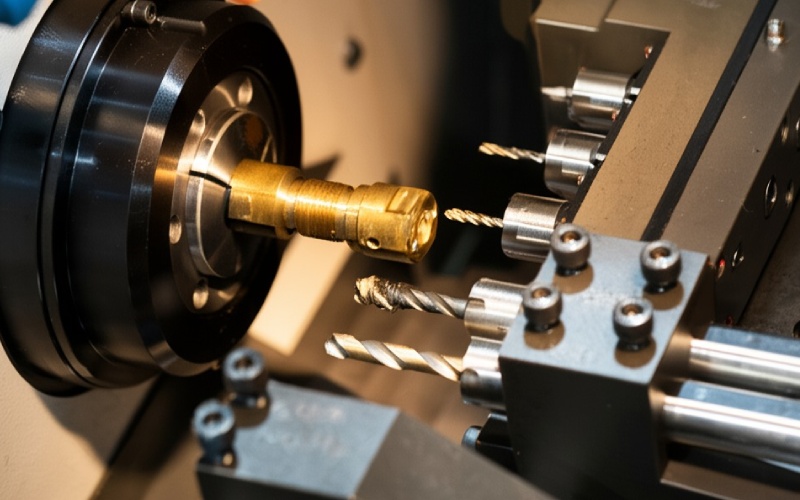

Different jobs need different machines. We have:

At Istar Machining, we work with many different alloys. Each one has special qualities for different jobs:

Aluminum is light but strong. It’s perfect when you need parts that don’t weigh much. We use different types:

Our team at Istar Machining has deep experience with aluminum CNC machining for all kinds of projects.

Titanium alloy is often used by our customers in the medical, aerospace, marine engineering, chemical equipment and other industries because it has some characteristics that other alloys do not have:

High strength-to-weight ratio: The strength is close to some steels, but the density is much lower.

Excellent corrosion resistance: It has strong resistance to seawater, chlorides and many chemicals.

Biocompatibility: It is non-toxic, does not react with human tissue, and is widely used in medical implants.

Good high temperature resistance: It can maintain strength at higher temperatures.

It has many varieties, among which Ti-6Al-4V (Grade 5) is the most commonly chosen by our customers.

Copper alloys are mainly divided into two types: Brass and Bronze

Bronze – Copper-tin alloy (may also contain aluminum, phosphorus, silicon, etc.)

Bronze is harder, more wear-resistant, and more corrosion-resistant than brass (especially seawater). It has good thermal/electrical conductivity. It has acceptable machinability, but not as good as C360 brass. Our customers often ask us to use it to customize: bearings, bushings, gears (worm gears), valve parts, ship propellers, sculptures, etc.

For the most demanding jobs, we work with special metals:

Industry | Parts We Make | Materials We Use | Benefits |

Aerospace | Engine parts, landing gear, brackets | 7075 Aluminum, Titanium, Inconel | Lightweight, heat-resistant, super strong |

Automotive | Transmission parts, suspension arms | 6061 Aluminum, Steel 4140 | Reduces car weight, strong and durable |

Medical | Surgical tools, implants | Grade 5 Titanium, Stainless Steel 316 | Safe for body contact, easy to sterilize |

Marine | Boat fittings, propeller shafts | 5083 Aluminum, Stainless Steel | Resists salt water damage |

Electronics | Heat sinks, housings | 6061 Aluminum | Helps cool hot parts, looks nice |

Energy | Turbine blades, valve parts | Inconel 718, Steel | Works in very hot places |

Industrial | Gears, bearings | 4140 Steel | Very hard-wearing for heavy use |

We know you need parts quickly:

After machining, we can add:

Our team knows all about different alloys and how to machine them perfectly. We can suggest the best material for your project.

We use high-speed carbide tools that make clean cuts with less waste. This saves money and makes better parts.

We offer design for CNC machining advice to make your parts easier to produce and less expensive.

Our efficient methods can save you 20-30% compared to other manufacturers.

At Istar Machining, we follow these steps to make your parts perfect:

We look at your design files to make sure they'll work well.

Our experts program the machines to cut your parts perfectly.

Our 5-axis machining centers or CNC turning equipment shape your parts.

We can add special finishes like anodizing or heat treatment.

One more check to make sure everything is perfect.

Getting your perfect parts from Istar Machining is easy:

A: We can make as few as 1 part for prototypes, or thousands for big projects.

A: Yes! Our engineers will look at your design and suggest changes to make it work better and cost less.

A: We use special anti-rust packaging and strong boxes to keep your parts safe.

A: We can work with most 3D files like STEP, IGES, X_T, or drawings in PDF format.

A: Most prototypes are ready in 3-5 days. Bigger orders usually take 10-14 days.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or