Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for a way to bend metal with perfect accuracy? CNC bending might be just what you need! At Istar Machining, we use computer-controlled machines to bend metal parts into exact shapes. Our high-tech process gives you better parts, saves material, and works faster than old-fashioned hand bending.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

We use Multi-Axis CNC Control systems that can:

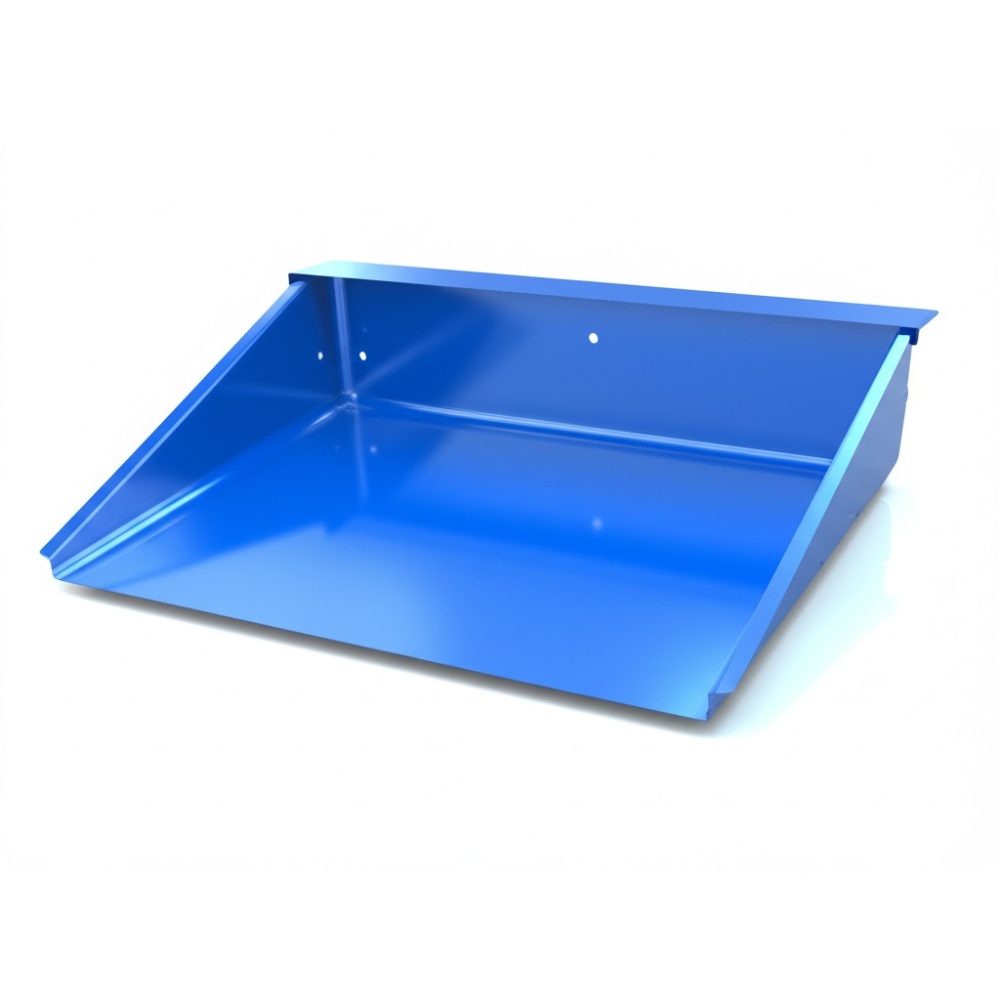

We utilize advanced CNC bending technology and deep material expertise to accurately form a wide variety of metals.

Highly versatile, strong, and cost-effective, steels are among the most common materials we bend. We handle various grades suitable for structural components, general fabrication, machine parts, and more.

Common Grades We Process:

Key Characteristics & Bending Notes:

Typical Forms: Sheet, Plate, Tube (Round, Square, Rectangular), Bar (Flat, Round, Square).

Selected for its superior corrosion resistance, durability, clean aesthetic, and hygienic properties, stainless steel is ideal for applications in food service, medical devices, architectural features, and harsh environments.

Common Grades We Process:

Key Characteristics & Bending Notes:

Typical Forms: Sheet (various finishes), Plate, Tube, Pipe, Bar.

Valued for its lightweight nature, excellent strength-to-weight ratio, and inherent corrosion resistance, aluminum is common in aerospace, automotive, electronics, and consumer products. Bending behavior is highly dependent on the specific alloy and temper.

Common Alloys & Tempers We Process:

Key Characteristics & Bending Notes:

Typical Forms: Sheet, Plate, Tube, Bar, Extrusions.

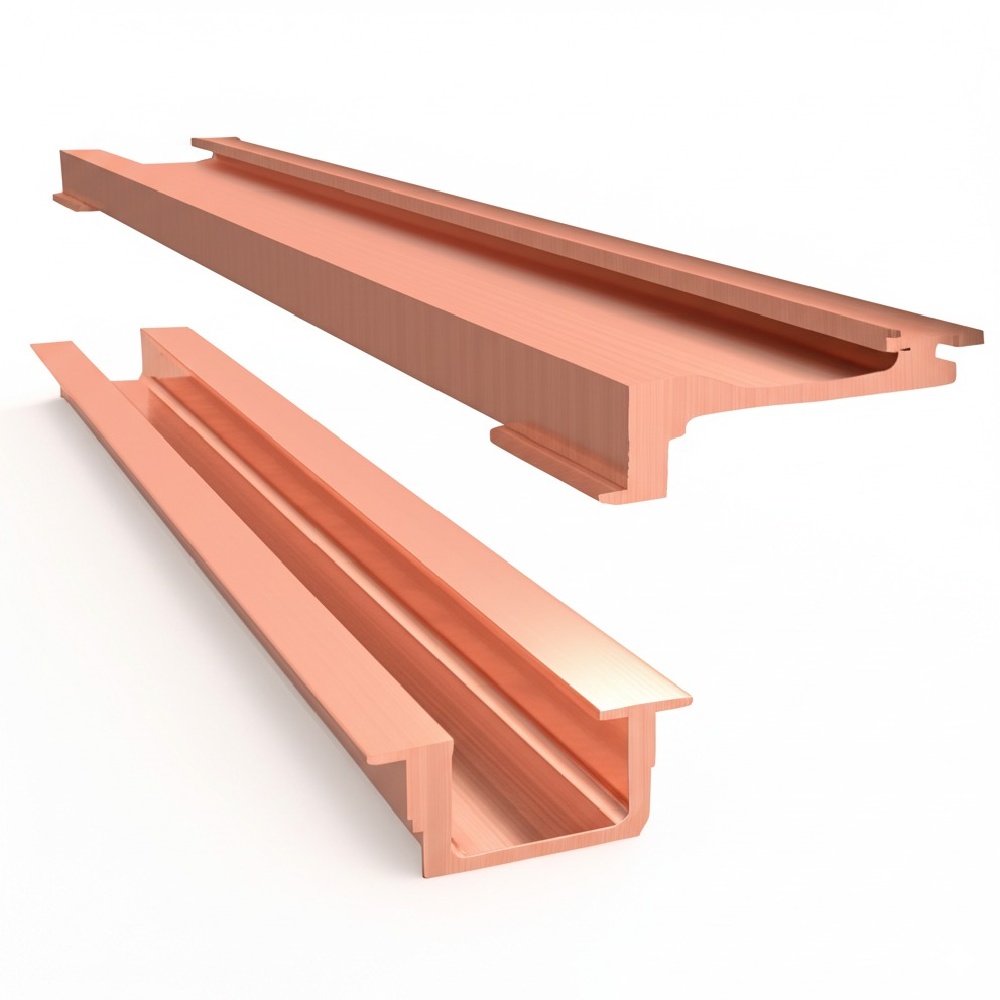

Copper is renowned for its outstanding electrical and thermal conductivity, used in electrical components and heat exchangers. Brass, a copper-zinc alloy, offers good machinability, corrosion resistance, and a desirable appearance for decorative and plumbing applications.

Common Grades We Process:

Key Characteristics & Bending Notes:

Typical Forms: Sheet, Strip, Plate, Bar, Tube.

Beyond the common materials, our expertise and equipment allow us to handle projects involving specialized metals, often used in demanding high-performance applications.

Examples We Can Process (Contact us for specifics):

Key Characteristics & Bending Notes:

Typical Forms: Sheet, Plate, Bar, Tube (Availability and forms can vary).

Considerations: Due to the specialized nature of these materials, please contact us directly to discuss your specific project requirements, material grades, and feasibility.

At Istar Machining, we help customers from many different industries:

Collapsible Mandrel Systems

These special tools go inside tubes to prevent collapse during tight bends. Great for thin-walled tubes!

In-Line Laser Welding

We can bend and weld aluminum brackets in one cycle, making production 40% faster!

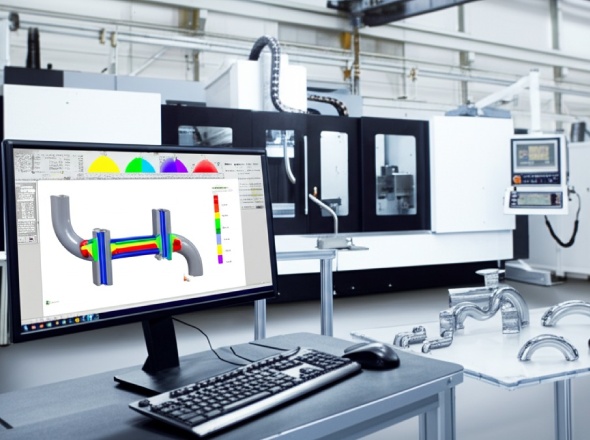

CAD/CAM Integration

Import your design files directly to our machines. We support:

AI-Optimized Toolpaths

Our smart software finds the best way to bend your parts:

Bending Type | Best For | Material Thickness | Accuracy |

Tube Bending | Pipes, frames, exhaust systems | 0.5mm-12mm | ±0.5mm |

Sheet Metal Bending | Panels, brackets, enclosures | 0.5mm-20mm | ±0.1° |

Profile Bending | Architectural pieces, furniture | 1mm-10mm | ±0.05mm |

3D Stretch Bending | Art installations, curved displays | 1mm-5mm | ±1mm |

Feature | CNC Bending | Traditional Bending |

Accuracy | ±0.05mm | ±1mm (varies by operator) |

Repeatability | Perfect across thousands of parts | Varies between operators |

Complex Shapes | Can create 3D multi-bend parts | Limited to simple bends |

Speed | Fast setup, quick production | Slow setup, operator-dependent |

Material Waste | Minimal with AI optimization | Higher waste rates |

Cost | Higher initial setup, lower per-part cost | Lower setup, higher labor costs |

Let’s look at how we turn flat metal into perfectly bent parts:

We start with computer files of your design

Our experts program the bending sequences

Our machines precisely bend the material

We measure to make sure everything is perfect

We clean up the parts and add any finishing touches

Ready to turn your flat metal into perfectly bent parts? Istar Machining is here to help! Our team of experts can guide you through the entire process from design to finished parts.

Contact us today for:

Email: [email protected]

Trust Istar Machining for all your CNC bending needs. With our precision equipment, expert team, and commitment to quality, we’ll make sure your parts are perfect every time!

CNC bending means using computers to control how metal gets bent. The “CNC” part stands for “Computer Numerical Control.” This technology lets us bend metal into complex shapes with very small mistakes – as little as 0.05mm off!

The cost depends on the material, complexity, and quantity. We offer per-bend pricing with minimum orders starting at 50 units.

Yes! We use special anti-ovalization tooling to keep square and rectangular tubes from getting distorted.

We work with DXF, STEP, and IGES files. Our team can also help convert your drawings if needed.

For most materials, we can bend down to 1.5 times the material thickness. For example, a 2mm thick sheet can be bent with a 3mm inside radius.

Small prototype runs can be done in 3-5 days. Larger production runs are scheduled based on complexity and quantity.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or