Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

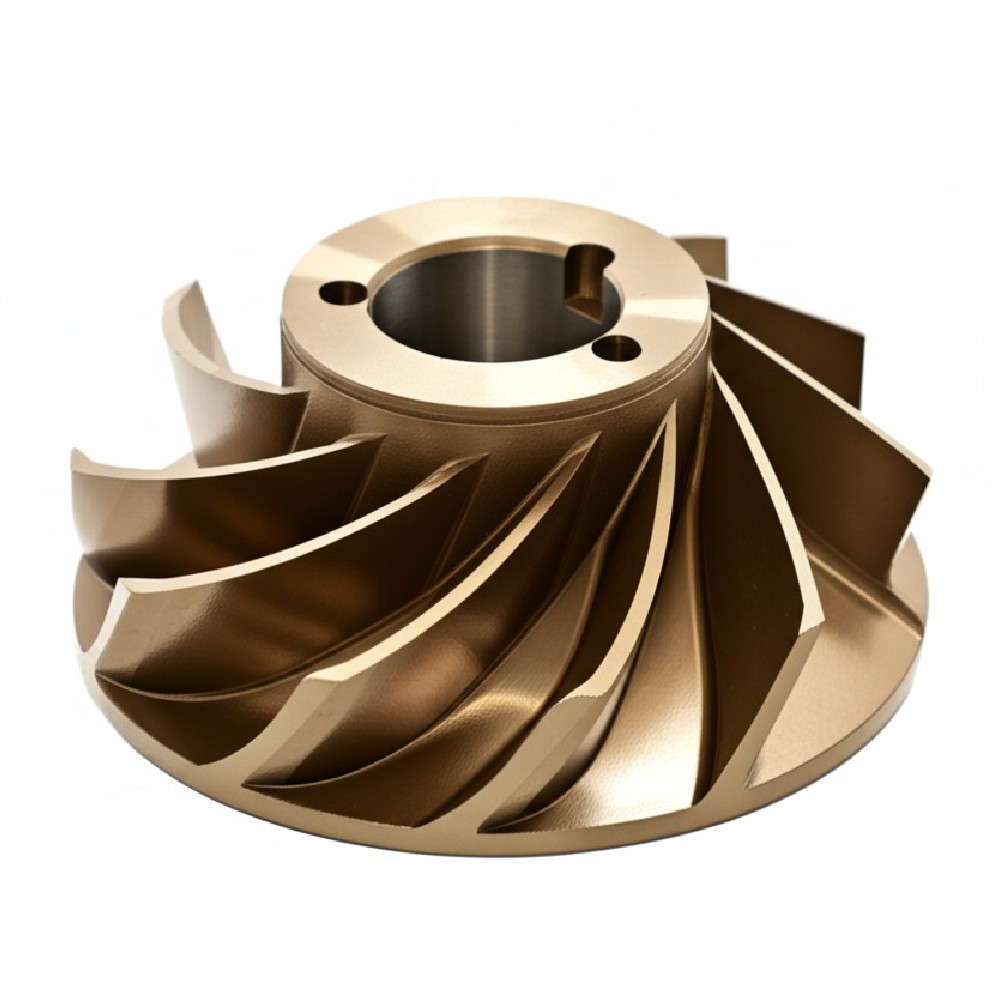

Are you looking for perfect holes in your parts? CNC boring might be just what you need! At Istar Machining, we make holes that are super exact – just like drawing a perfect circle every time. We have the tools, skills, and machines to make your parts work better than ever.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Different materials are better for different jobs. Here’s what works best:

Aluminum is a star for boring. It’s light and cuts easy.

Good things about aluminum:

Types of aluminum:

Boeing made plane parts 30% faster by using good tools with aluminum.

For more info on aluminum, check out aluminum CNC milling.

Stainless steel does not rust easy. It’s good for wet places and body parts.

Good things about stainless steel:

Types of stainless steel:

A medical company made surgery tools with a super smooth finish using stainless steel.

Learn more about CNC stainless steel for your jobs.

Tool steels are very strong and tough.

Good things about tool steels:

Types of tool steels:

Ford made engine parts 18% cheaper by using the right speeds for boring tool steel.

Titanium is strong but not too heavy. It’s good for planes and body parts.

Good things about titanium:

Airbus cut bad parts by 25% with high-pressure water when boring titanium.

For special jobs with titanium, visit titanium CNC machining.

These special metals work in very hot places.

Good things about Inconel:

Not so good:

GE made jet engine parts last 200% longer by using special tools for Inconel.

Plastics can be good for light parts that don’t need to be strong.

Good things about plastics:

PEEK is a special plastic good for body parts.

Stryker saved 40% on costs by using PEEK for spine parts.

To learn about plastic options, see CNC plastic.

Our CNC boring service helps many different businesses make better products:

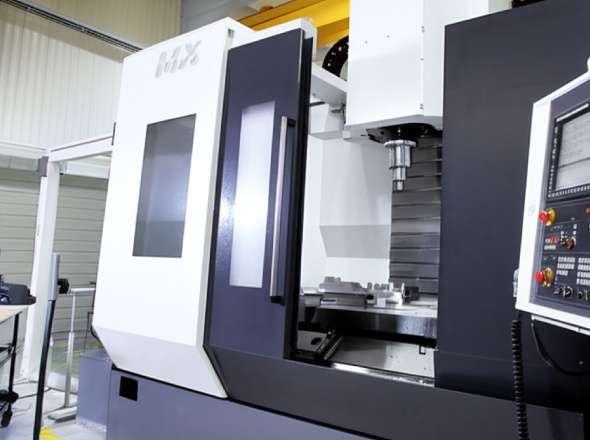

We invest in the best machines so your parts are always perfect:

For the engineers and quality folks, here are the specs:

Service Type | What It Does | Best For |

Precision Boring | Makes holes with exact sizes (±0.005mm) | Aerospace parts, medical devices |

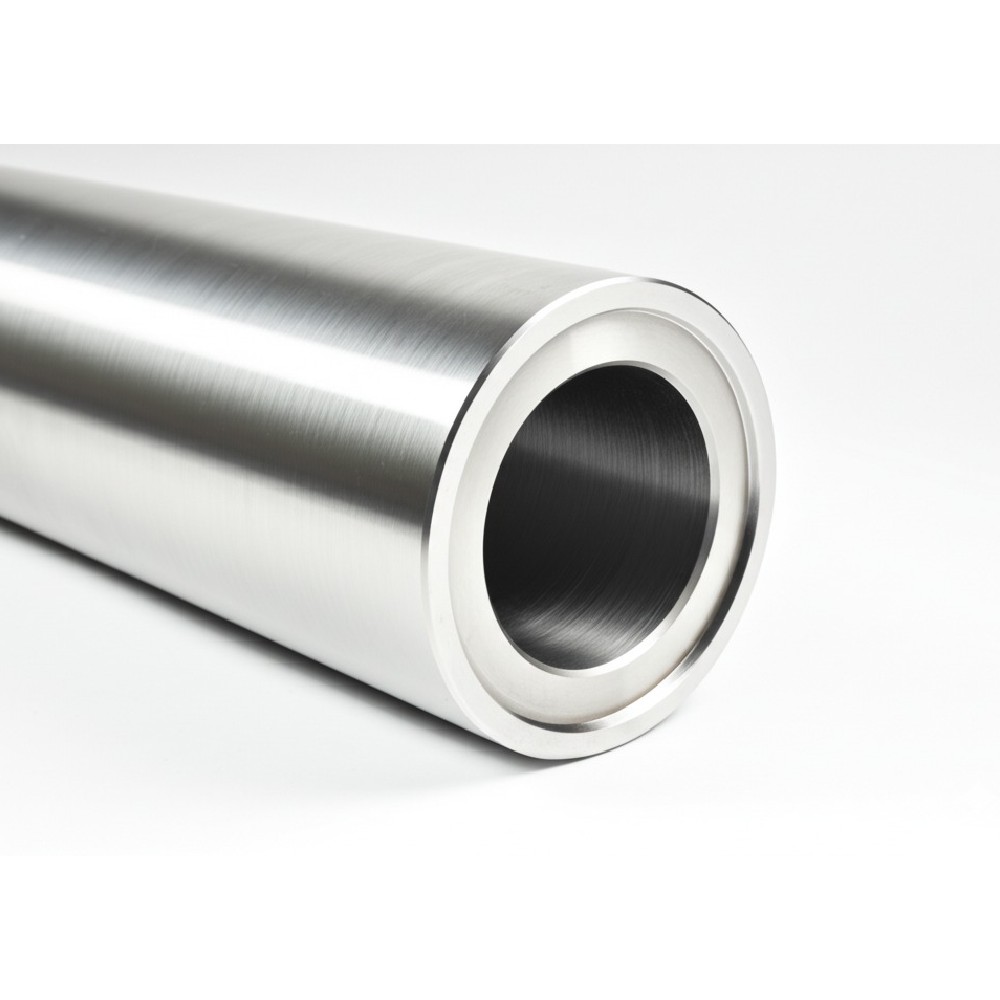

Deep-Hole Boring | Creates long, straight holes | Hydraulic cylinders, gun barrels |

Counter-Boring | Makes wider openings at the start of holes | Bolt heads, washers |

Back-Boring | Works from the back side of parts | Hard-to-reach areas |

Trepanning | Cuts large holes while saving material | Big openings, saving material |

Process | Good For | Limitations | When to Choose |

CNC Boring | Improving existing holes, high precision | Needs pre-existing hole | When accuracy is critical |

Drilling | Making new holes quickly | Less accurate than boring | For rough holes or starting points |

Reaming | Finishing holes to size | Limited material removal | When hole is close to final size |

EDM | Hard materials, odd shapes | Slower, more expensive | For hardened steel or complex shapes |

We don’t just make holes – we make perfect holes! Here’s why customers pick us:

We can make holes with ±0.005mm precision - that's thinner than a human hair!

Our CNC machines work day and night without getting tired or making mistakes

We can bore holes in metal, plastic, and more

We use special boring bars and cutting tools for perfect results

Whether it's for planes, cars, or medical tools - we've got you covered

Ready for perfect holes in your parts? Here’s how:

CAD files work best but drawings are fine too

We'll tell you the price and time needed

We'll make your parts exactly to spec

On time and ready to use

Ready to get started? Call us, email us, or visit our website. We’re here to make holes that help your products work better!

Istar Machining – Making the perfect hole, every time.

CNC boring is a special way to make or fix holes in parts. Unlike drilling that just makes new holes, boring makes existing holes better – smoother, more round, and exactly the right size. Our CNC machining service experts use computer-controlled machines to make holes that meet your exact needs.

Drilling makes new holes, but boring makes existing holes better – more exact in size, shape, and smoothness.

We can make holes with ±0.005mm precision – that’s about 1/5 the width of a human hair!

Yes! With our special tools, we can make holes up to 10 times deeper than their width.

Almost anything – aluminum, steel, titanium, plastics, copper, and more. Each material needs the right tools and speeds.

We check every critical hole with precise measuring tools. For important jobs, we use special sensors during machining.

It costs more than simple drilling but delivers much better quality. For parts where holes really matter, it’s worth it!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or