Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

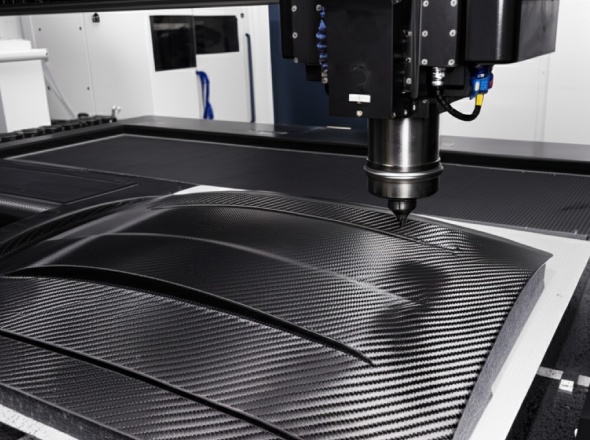

Composite CNC machining is a special way to shape and cut materials made from two or more different substances mixed together. At Istar Machining, we use high-tech computer-controlled machines to make exact parts from these strong but light materials.

Our team works with many types of composites like carbon fiber, fiberglass, and Kevlar®. These materials are super strong but also very light, which makes them perfect for planes, cars, sports gear, and medical tools.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Composite materials give you special benefits that regular materials like metal or plastic can’t match:

At Istar Machining, our 5 axis machining equipment lets us make even the most complex composite parts with perfect precision.

Our composite CNC machining helps many different industries:

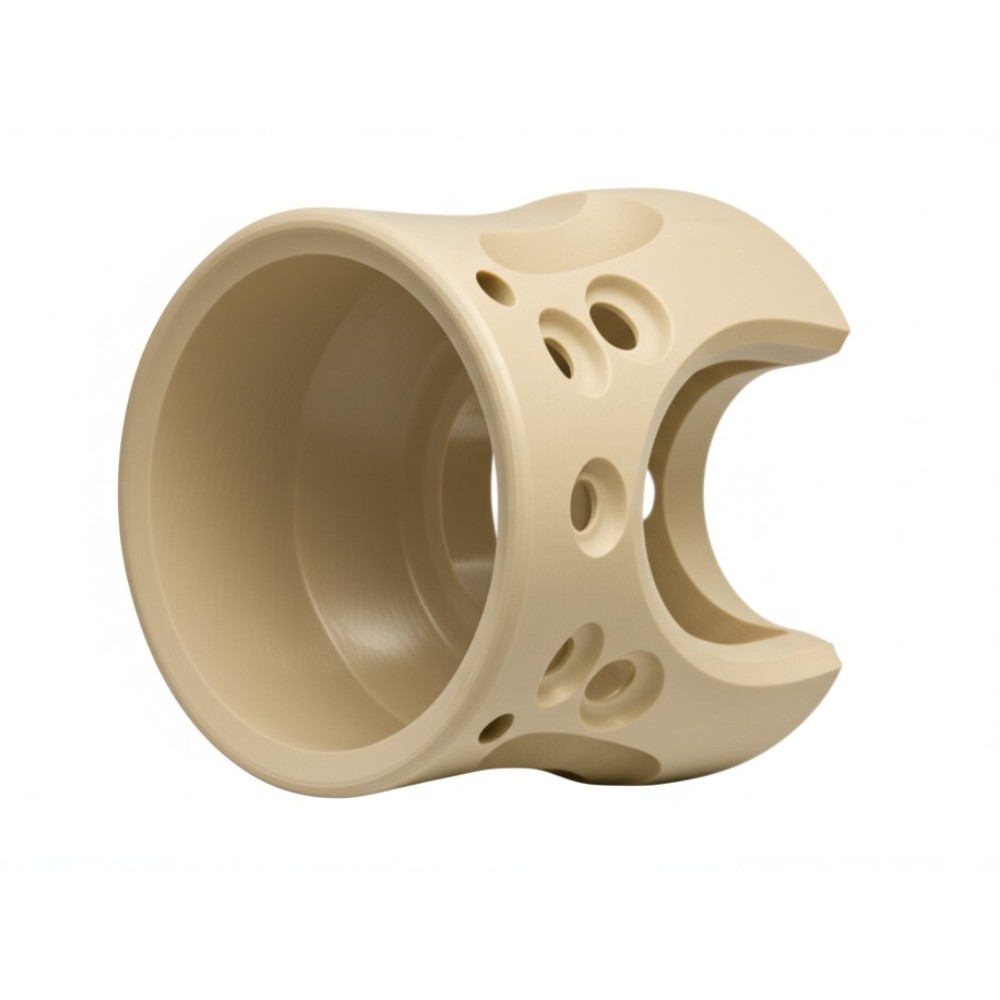

At Istar Machining, we have years of experience working with many different composite materials:

Carbon fiber is super strong but very light. We use our carbon fiber CNC machining services to make parts for:

Also called fiberglass, this material is stronger than plastic but costs less than carbon fiber. Our fiberglass CNC machining creates:

Known for being bullet-resistant, we machine Kevlar® composites for:

These mix different fibers together for the best properties. We make:

These have a pattern like a beehive inside. We machine these for:

We use only the best tools and machines for working with composites:

Machine Type | What It Does | Why It Matters |

5-axis CNC machines | Cuts material from 5 different angles | Makes complex shapes with fewer setups, saving time |

Diamond-coated carbide tools | Cuts tough composites without wearing down | Creates clean edges on carbon fiber without fraying |

High-speed spindles (24k–48k RPM) | Spins cutting tools very fast | Perfect for detailed work on medical parts |

Dust extraction systems | Removes harmful dust while cutting | Keeps workspace safe when cutting fiberglass |

Ultrasonic edge trimming | Uses sound waves to cut cleanly | Makes smooth edges on bike frames and sports equipment |

When you work with us, you get:

We understand how different composites behave when machined

Our parts meet the tightest tolerances (±0.003" or better)

Every part is checked multiple times

5-10 days for most orders, with rush options available

We can help if your design needs adjustments

Competitive rates for all projects

At Istar Machining, we follow a careful step-by-step process:

First, we look at your design and make sure it will work well with CNC machining. We use special computer programs to plan the best way to cut your part.

We pick the exact right tools for each material:

Diamond-coated end mills for carbon fiber

Special drill bits for fiberglass

Carbide tools for aramid fibers

Our advanced machines can cut from any angle, which means:

Complex shapes are possible

Fewer setups needed

Better accuracy

Smoother surfaces

After machining, we:

Remove any rough edges

Clean the parts thoroughly

Check every measurement

Make sure the finish is perfect

Ready to bring your composite project to life? Istar Machining is your trusted partner for precision composite CNC machining. With our advanced equipment, expert team, and dedication to quality, we’ll help you create perfect parts every time.

Contact us today to:

Email: [email protected]

Most composite CNC machining services cost between $50-$250 per hour, depending on the material and complexity. Special materials like PEEK cost about 20% more than standard options like G10.

Yes! We use special ultrasonic cutting tools and diamond-coated bits that give clean edges without fraying or delamination.

Most orders take 5-10 days, but we have rush options for urgent needs. Larger orders of 100+ parts might take slightly longer.

We regularly achieve tolerances of ±0.003″ for most composite materials, and can reach ±0.001″ for critical dimensions when needed.

Yes, we can provide clear coat finishes, painting, polishing, and other surface treatments for composite parts.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or