Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

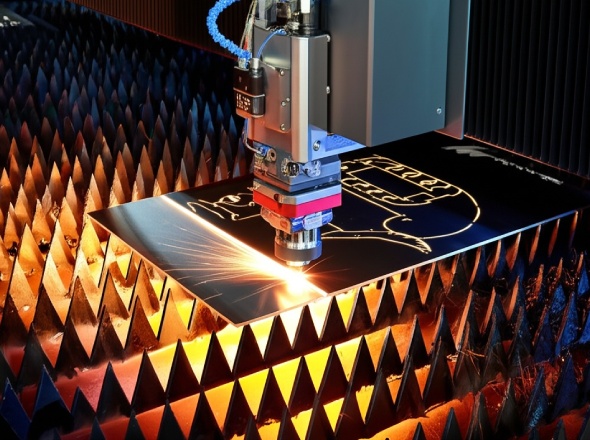

Are you looking for a way to cut materials with perfect precision? At Istar Machining, we use computer-controlled machines to cut materials exactly how you want them. Our CNC cutting service uses computers to guide cutting tools that make perfect shapes every time.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

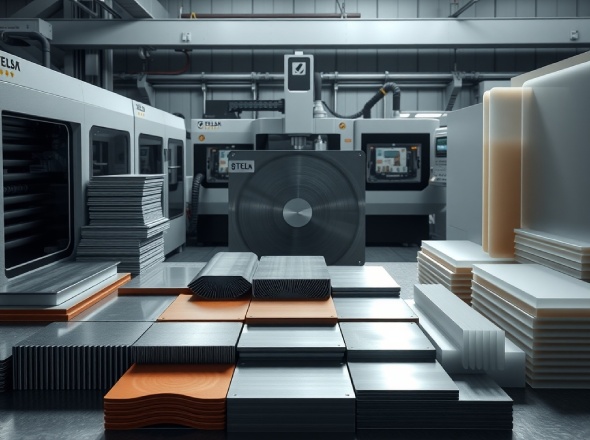

We use different cutting tools based on what works best for your project:

Laser cutting uses a powerful light beam to cut through materials. It's super precise and leaves a clean edge. It works great for thin metals and plastics.

Waterjet cutting uses a high-pressure stream of water with tiny bits of sand to cut through materials. It can cut almost anything!

Plasma cutting uses a hot electrical arc to melt through metal. It's fast and good for thicker metals.

At Istar Machining, we can cut almost any material you need. Here are the main types:

Metals

Aluminum alloys are a cornerstone of modern manufacturing, prized for being lightweight, corrosion-resistant, and easy to machine. They offer an excellent strength-to-weight ratio and won’t rust, making them incredibly versatile.

We commonly work with grades like:

This makes aluminum ideal for parts such as:

Known for its superior corrosion resistance and durability, stainless steel offers a combination of strength, aesthetic appeal, and hygiene. It’s a go-to material for tough environments or applications demanding cleanliness.

Popular grades we handle include:

Typical applications benefit from these properties:

Carbon and alloy steels are strong, durable, and cost-effective, valued for their machinability and robustness. While base carbon steels require finishing to prevent rust, various grades offer tailored properties like hardenability or added strength through alloying elements.

We frequently machine types including:

Their strength lends itself well to:

Specifically engineered for high hardness, wear resistance, and toughness, tool steels are essential for creating durable tooling and components that withstand demanding operations. Machining often requires specialized techniques.

Key grades we process:

Used primarily for manufacturing:

For applications demanding the ultimate strength-to-weight ratio and exceptional corrosion resistance, titanium is often the answer. It performs well at high temperatures and is biocompatible.

Key grades we process:

Its unique properties are critical for:

Copper boasts excellent electrical and thermal conductivity. Brass (Copper-Zinc) offers good machinability, corrosion resistance, and a decorative look. Bronze (Copper-Tin, Aluminum, etc.) provides good wear resistance, strength, and corrosion resistance.

Common Grades We Cut:

Ideal For Parts Such As:

Plastics

A strong, stiff engineering plastic with low friction, excellent wear resistance, dimensional stability, and good machinability. Resistant to many solvents and moisture.

Common Types We Cut:

Ideal For Parts Such As:

Known for its toughness, wear resistance, impact strength, and good chemical resistance. Can absorb moisture, which affects dimensional stability and properties; consider variants or design accordingly.

Common Types We Cut:

Ideal For Parts Such As:

Offers excellent optical clarity, UV stability, weather resistance, and a wide range of colors. Relatively rigid but brittle compared to PC or PETG. Machines well for smooth, polished finishes (cast preferred). Laser cutting is also highly effective.

Common Types We Cut:

Ideal For Parts Such As:

Extremely high impact resistance (virtually unbreakable), good temperature resistance, and good optical clarity (though less than acrylic). More durable and flexible than acrylic. Can be prone to stress cracking with certain chemicals.

Common Types We Cut:

Ideal For Parts Such As:

HDPE (High-Density) is cost-effective, chemical resistant, impact resistant, and FDA compliant grades available. UHMW (Ultra-High Molecular Weight) offers extremely high abrasion resistance, impact strength, and low friction. LDPE (Low-Density) is softer and more flexible.

Common Types We Cut:

Ideal For Parts Such As:

We also work with a variety of other performance plastics tailored to specific needs like chemical resistance, temperature performance, or electrical insulation.

Examples We Can Cut:

Our machines can handle different thicknesses based on the material:

Metal Thickness Range:

Plastic Thickness Range:

We can make prototype parts in 3-5 days. Larger orders take about 2 weeks, which is much faster than many other shops. eiusmod

Our machines cut with amazing accuracy: For metals: within ±0.005" (about the width of a human hair) For plastics: within ±0.010"

We have over 23 years of experience cutting parts for all kinds of industries. Our team knows exactly how to make your parts right.

We're proud to hold ISO 9001 and AS9100 (aerospace) certifications, which means we follow strict quality rules.

Getting parts made at Istar Machining is simple:

Upload your CAD file (DXF, STEP, or SolidWorks)

We'll tell you how much it costs right away

Production begins within 24 hours

Every part is inspected before sending

Ready to get your parts made? Here’s how to begin:

You can upload your designs right now or call us to discuss your project. Istar Machining is ready to help make your ideas real with our precision CNC cutting services.

Think of CNC cutting like using scissors, but with super-human accuracy that never makes a mistake! Our machines follow a computer program to cut materials into the exact shapes you need. This is much better than cutting by hand because it’s faster, more exact, and can make the same part over and over without mistakes.

Aluminum and stainless steel are great for outdoor use because they don’t rust. For plastics, UV-resistant acrylic or polycarbonate works well.

Yes! We make anywhere from 1 to 10,000+ pieces. We’re happy to make just a few parts for a prototype or thousands for production.

We work with DXF, STEP, IGES, SolidWorks, and PDF files. DXF is best for 2D cutting projects.

Rush orders can be ready in as little as 24-48 hours for simple parts. Standard orders typically take 3-5 days for prototypes and 2 weeks for larger orders.

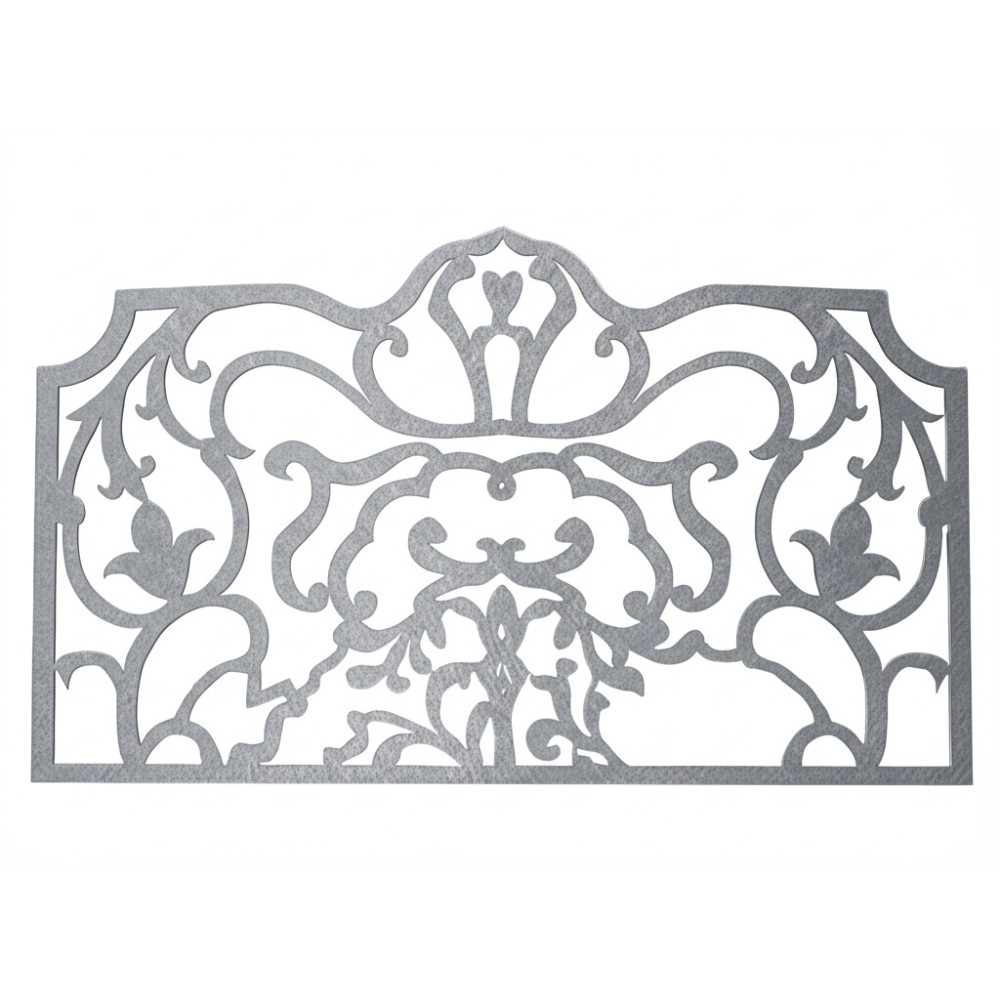

Yes! Our laser cutting is perfect for intricate details down to 0.5mm in size. Waterjet cutting can also make detailed cuts in thicker materials.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or