Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

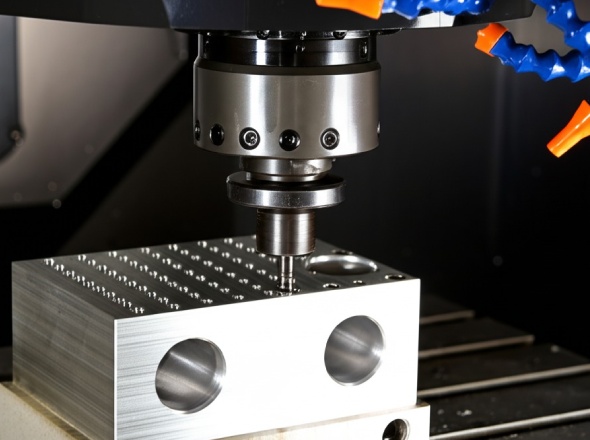

Welcome to our CNC drilling services at Istar Machining. We make perfect holes in all kinds of materials using computer-controlled machines. Our team helps with projects big and small, from aerospace parts to medical tools. Let’s learn how CNC drilling works and why it’s great for your projects!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

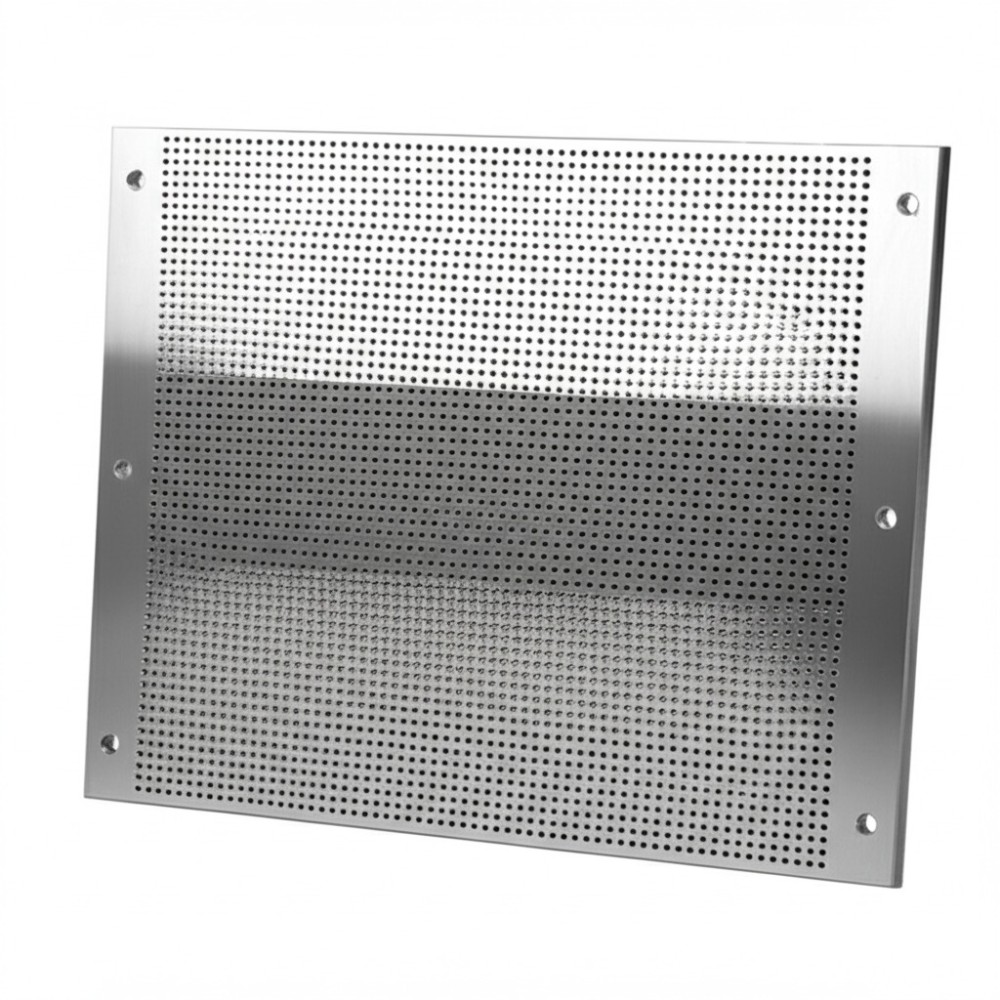

Different materials are better for different jobs. Here’s what works best:

Metals

Aluminum is a top pick for CNC drilling. It is:

Best grades:

When drilling aluminum, use:

Aluminum has a machinability rating of 80-90%. This means it is very easy to drill!

Stainless steel is hard but good for parts that must not rust.

Types:

When drilling stainless steel:

In one test, carbide bits made 1,200-1,500 holes in stainless steel. HSS bits only made 300-500 holes.

Titanium is very strong but light. It is used in:

Titanium is hard to drill (25% machinability). You need:

One case study showed that using peck drilling with the right bits made titanium drill bits last 30% longer!

Brass is the easiest metal to drill (100% machinability). It is the gold standard! Brass is used for:

Copper is good for:

For brass and copper:

A test showed that using TiN-coated HSS bits made drilling brass 20% faster!

Plastics & Composites

PEEK plastic is high-end and used in:

PEEK has 70-85% machinability. For drilling it:

Nylon is tough and slick. Good for:

Carbon fiber is very strong but light. It is used in:

Carbon fiber is hard to drill well (30-50% machinability). You need:

Clear plastics like acrylic are good for:

When drilling clear plastics:

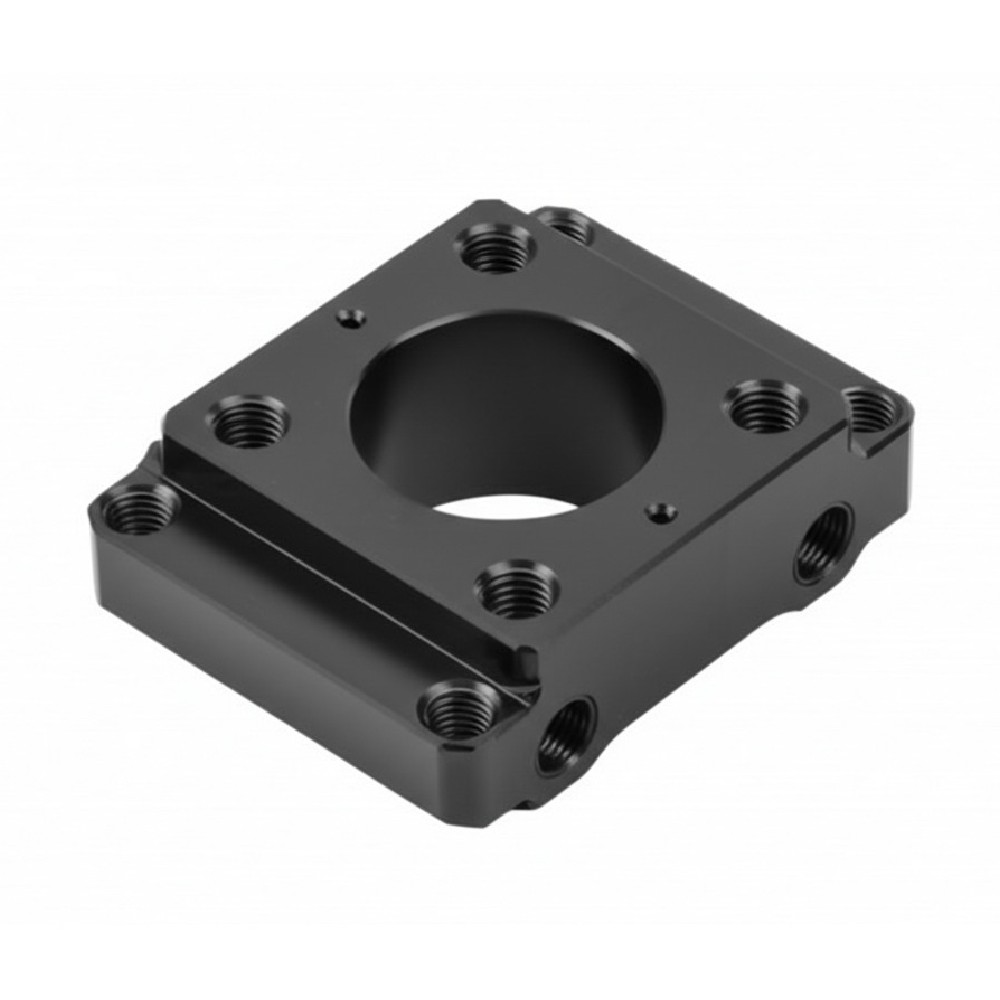

For those who want to know the specifics, here’s what powers our CNC drilling operations:

Our team has years of experience with precision machining across many industries. We know how to handle complex projects and solve tough drilling challenges.

Beyond just drilling, we offer a full range of services including CNC milling and CNC turning to complete your parts under one roof.

Whether you need one prototype or thousands of parts, our CAD/CAM integration and automatic tool changers help us scale to your needs quickly.

Our ISO 9001 certification means every part meets strict quality standards. We use advanced measurement tools to verify each hole's dimensions and position.

We understand how different materials behave during drilling. From tough aerospace alloys to delicate plastics, we adjust our approach for perfect results.

The journey from idea to perfect part is smooth with Istar Machining:

We help refine your design for optimal drilling

Choose from our wide range of materials

We develop the most efficient process

Every part is inspected to ensure perfection

Your parts arrive exactly when promised

Ready to experience the Istar Machining difference? Contact us for a quote on your CNC drilling project. Our team will help you choose the right process, material, and finishing options for your specific needs.

Whether you need prototype parts or full production runs, our automated drilling capabilities deliver consistent quality, on time and on budget. With our precision machining expertise and commitment to excellence, your project is in good hands.

Contact Istar Machining today and discover why leading companies trust us with their most demanding CNC drilling projects.

Our machines work with amazing accuracy – down to ±0.001″! This means:

For projects that need even more precision, check out our ultra precision machining services.

We offer both standard drilling and 5-axis drilling services, which means:

Our carbide/HSD drill bits stay sharp longer and can handle tough materials like:

Plus, our automatic tool changers mean we can switch between different drill bits without stopping the machine, making your project faster and more cost-effective.

Our high-pressure coolant systems are crucial for success:

We follow strict standards with our ISO 9001 certification:

If you care more about appearance, corrosion margin and extrusion-friendly shapes, 6063-T52 usually wins. If you care more about structural

If you work in construction, fabrication, CNC machining, product design, or procurement, you’ve probably hit this exact moment: “The drawing

You almost never choose between a bearing and a bushing because of friction alone. You choose because of how you