Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

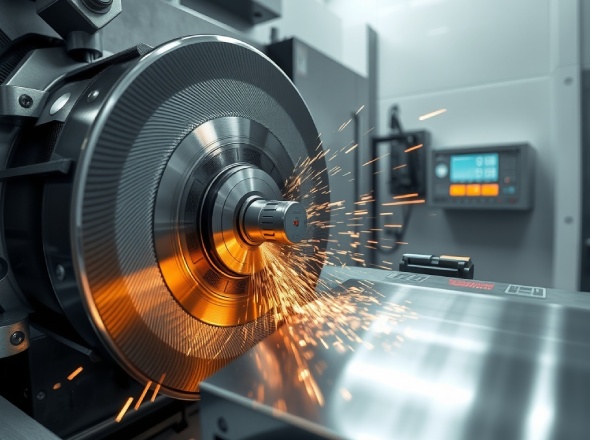

Are you looking for perfect finishes on hard parts? Do you need parts made with no errors? CNC grinding might be just what you need! At Istar Machining, we use computer-controlled grinding machines to make parts that fit together perfectly.

CNC grinding is like a special kind of cutting that uses spinning wheels covered in tiny hard bits. These wheels rub against metal and other materials to make them smooth and exactly the right size. Let’s learn all about it!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

CNC grinding uses computer-controlled machines to shape parts using abrasive wheels. Unlike other cutting tools, grinding wheels have thousands of tiny cutting edges. This helps us make parts with:

Our CNC machining service experts program these machines to move the grinding wheel or the part in exact paths. This creates the perfect finish every time!

We have many kinds of grinding to match your needs:

Precision grinding of external diameters (OD), internal diameters (ID), or tapers on rotating parts. Achieves high accuracy (tolerances < 5µm), roundness, concentricity, and excellent surface finishes (Ra < 0.4µm).

Best for: Precision shafts, pins, bearing races, sleeves, spindles.

Produces highly accurate flat, parallel, or profiled surfaces. The workpiece moves under a rotating grinding wheel, yielding exceptional flatness (< 5µm) and mirror-like finishes (Ra < 0.2µm).

Best for: Mold components, precision gauge blocks, flat plates, tool sharpening, reference surfaces.

Efficiently grinds external cylindrical surfaces. The workpiece is supported by the grinding wheel, regulating wheel, and work rest blade. No centering needed, highly productive (ideal for high volume), achieving excellent roundness and finish.

Best for: High-volume pins, rollers, hydraulic spools, tubes, precision bar stock.

Specialized for manufacturing or re-sharpening complex, multi-edged cutting tools. Often uses multi-axis (e.g., 5-axis) CNC machines to precisely grind cutting edges, flutes, and complex geometries, ensuring sharpness and performance.

Best for: Manufacturing and re-sharpening drills, end mills, reamers, taps, form tools.

Feature | What It Means For You |

±0.0001″ Tolerance | Your parts fit together perfectly every time |

Grinds Hard Materials (HRC 60+) | We can work with super hard steels that other methods can’t handle |

45 m/sec Grinding Wheel Speed | Faster production without losing quality |

Surface Finish ≤0.4 µm Ra | Parts so smooth they sometimes don’t need more polishing |

Handles Parts Up To Ø500 mm x 1500 mm | We can work on small precision parts or large components |

Our CNC parts machining team uses the best Fanuc and Siemens controls to make sure every grinding job is done right.

CNC Grinding excels at producing parts with exceptional precision, tight tolerances, and superior surface finishes, especially on hard or difficult-to-machine materials. Here are some of the common materials we work with:

Metals

(Common Grades: Tool Steels like A2, D2, O1, M2; Bearing Steels like 52100; Alloy Steels like 4140, 4340 after heat treatment) possess high hardness, strength, and wear resistance achieved through heat treatment. Grinding is often the essential final step to achieve precise dimensions and fine surface finishes after hardening.

Good for:

Why customers love it: “Grinding allows us to achieve critical tolerances and mirror-like finishes on extremely hard steel components after heat treatment, ensuring maximum performance and longevity.”

(Common Grades: 303, 304, 316, 440C, 17-4 PH) offers excellent corrosion resistance and good strength. Grinding is used for high-precision applications, achieving fine finishes, or machining hardened grades like 440C or precipitation-hardened grades like 17-4 PH.

Good for:

Why customers love it: “It delivers high precision and excellent finishes on corrosion-resistant parts, essential for medical, aerospace, and food-grade applications, even on hardened variants.”

(Common Grades: A2, D2, O1, S7, M2, H13) are specifically formulated for high hardness, wear resistance, toughness, and heat resistance, making them ideal for tooling. Grinding is the primary method for shaping and sharpening these materials after hardening.

Good for:

Why customers love it: “Enables the creation of highly accurate, durable tooling with sharp edges and complex geometries from extremely hard, wear-resistant materials.”

(Common Grades: Grade 5 / Ti-6Al-4V, Grade 2) are known for their high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Grinding is often necessary for achieving tight tolerances and fine finishes due to titanium’s machining characteristics.

Good for:

Why customers love it: “Allows for high-precision manufacturing of lightweight, strong, and biocompatible components for demanding aerospace and medical applications.”

(Common Grades: Inconel® 625, 718; Hastelloy® C276; Monel® 400) offer exceptional performance at high temperatures and in corrosive environments. These alloys are notoriously difficult to machine, making grinding a crucial process for finishing and achieving precision.

Good for:

Why customers love it: “Grinding provides a reliable method to achieve precise dimensions and smooth surfaces on materials designed to withstand extreme heat and corrosive conditions.”

(Cemented Carbide) is an extremely hard and wear-resistant composite material made from tungsten carbide particles bonded with a metal binder (usually cobalt). Grinding, often with diamond wheels, is the standard method for shaping and finishing carbide parts.

Good for:

Why customers love it: “It’s the essential process for shaping ultra-hard carbide, creating exceptionally durable and wear-resistant tools and components with precise geometries.”

Ceramics

(Common Grades: AD 96, AD 99.5, AD 99.8) is a very hard, wear-resistant, and electrically insulating technical ceramic. Grinding is required to achieve precise shapes and tolerances due to its hardness.

Good for:

Why customers love it: “Enables the fabrication of highly accurate parts from a durable, wear-resistant, and electrically insulating material suitable for demanding environments.”

(Common Grades: Y-TZP) is known for its exceptional toughness, strength, and wear resistance among ceramics. Precision grinding is used to shape this high-performance material.

Good for:

Why customers love it: “Allows for precise manufacturing of components from an incredibly tough and wear-resistant ceramic that often outperforms metals in wear applications.”

(Common Grades: Sintered SiC, Reaction Bonded SiC) is extremely hard, has excellent thermal conductivity, chemical resistance, and retains strength at very high temperatures. Grinding is necessary for precision shaping.

Good for:

Why customers love it: “Makes it possible to create precise components from an ultra-hard material ideal for high-temperature, high-wear, and chemically aggressive applications.”

Offers a unique combination of high strength, toughness, thermal shock resistance, and wear resistance. Grinding is essential for achieving the required precision on finished parts.

Good for:

Why customers love it: “Grinding enables the production of high-precision components offering superior toughness, thermal stability, and wear resistance for extreme operating conditions.”

Jet engines need parts that can handle extreme heat and stress. Our grinding creates turbine blades and landing gear parts that meet strict aerospace rules.

Doctors need tools and implants that are perfectly made. We grind surgical instruments and joint replacements that help save lives.

Cars need parts that last for years. We grind crankshafts and gears that keep engines running smoothly.

Here’s how we make your parts perfect:

Our surface grinding services team can help you get the perfect finish on your flat parts too!

Ready to get the perfect parts for your project? Our team is ready to help!

Contact our team today to learn how our precision grinding can solve your toughest machining challenges.

A: Grinding uses abrasive wheels to remove tiny amounts of material, making very smooth finishes. Milling uses cutting tools with defined edges and removes material faster but leaves a rougher finish.

A: We can grind almost any material including hardened steels, titanium, Inconel, ceramics, and carbides. Some plastics can be ground too.

A: Simple parts might take just hours, while complex parts can take days. Our standard turnaround is 5 days, but we can work faster if you need it.

A: Cylindrical grinding holds the part at both ends while it spins. Centerless doesn’t clamp the part at all, making it better for thin parts and high-volume work.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or