Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for strong iron parts made with cutting-edge technology? At Istar Machining, we turn blocks of iron into perfect parts for your projects. From brake disks that stop cars to pump housings that move water, our iron parts work hard in tough places.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

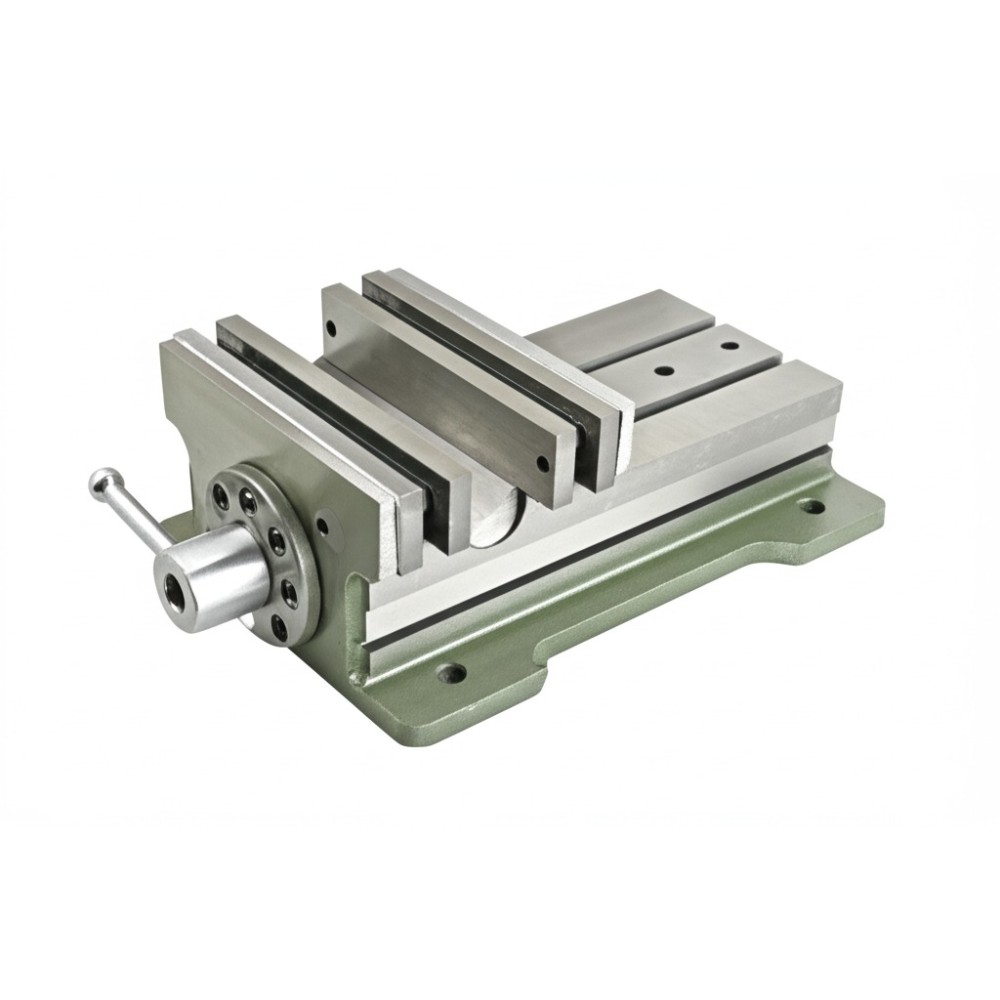

At Istar Machining, we offer many ways to shape iron into the parts you need:

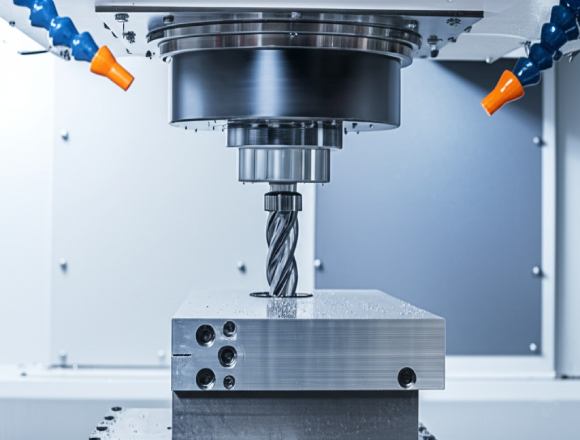

Our 5 axis machining service can create the most complex iron parts. The cutting tool moves in five different directions at once, reaching spots that simpler machines can't touch.

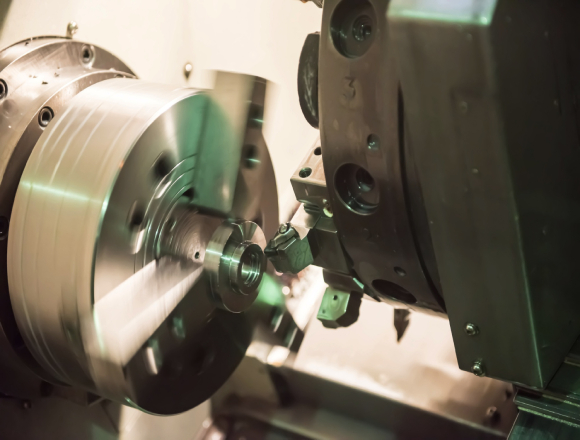

We make perfectly round iron parts with tight tolerances of ±0.001 inches. This is perfect for shafts, pulleys, and other spinning parts.

When you need super-smooth iron surfaces, our cylindrical grinding services can make surfaces as smooth as glass.

We work with different kinds of iron to match what you need:

Cast iron has lots of carbon (2.5-4%). This makes it:

There are a few kinds of cast iron:

Gray Iron (ASTM A48)

Ductile Iron (EN-GJS-400-18)

White Iron

Wrought iron has very little carbon (less than 0.08%). It has fibers inside that make it:

It is most used for:

Wrought iron is not used much in modern CNC machining services except for making pretty things.

This is very clean iron with few other things mixed in. Butter iron is a type that is 99.8% pure iron. It is used for special jobs that need very pure metal.

Metal | When to Choose It | When Iron Is Better |

Iron | For vibration damping, heat resistance | When strength and low cost matter most |

When light weight is crucial | When wear resistance matters more than weight | |

For higher strength needs | When castability and vibration damping are important | |

For electrical conductivity | When magnetic properties are needed |

We can give your iron parts different finishes:

For engineers and buyers who need specific facts:

Compliance: RoHS and REACH standards for safety

Part Size: Up to 36″ x 24″ x 18″ for single pieces

Optimized Cutting Paths: Less waste, faster production

When you choose us for iron CNC machining, you get:

5-7 days for prototypes, 2-4 weeks for production runs

ISO 9001:2015 certified processes

Engineers who understand your needs

Great value for precision parts

From raw material to finished part

From one prototype to thousands of production parts

When you work with Istar Machining, here’s what happens:

Send us your CAD files

Get pricing within 24 hours

Your parts are made on our precision machines

Every part is checked carefully

Parts are cleaned and finished as needed

Need something special? Our custom CNC machining service can make iron parts that fit your exact needs. Just send us your design, and we’ll make it real.

We can help with:

A: Iron CNC machining uses computer-controlled tools to shape iron into exact parts. Our machines follow digital plans to cut, drill, and shape iron with perfect accuracy. Istar Machining has top-notch tools to make iron parts that fit just right in your projects.

A: Iron is often easier to machine than steel, costs less, and absorbs vibrations better. Steel is stronger but can be harder to work with.

A: Yes! We can hold tolerances of ±0.001″ on our iron parts, which is perfect for most precision applications.

A: We offer as-machined finishes, grinding for smoother surfaces, zinc plating for rust protection, and powder coating for color and durability.

A: Prototypes typically take 5-7 days. Production runs take 2-4 weeks depending on complexity and quantity.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or