Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

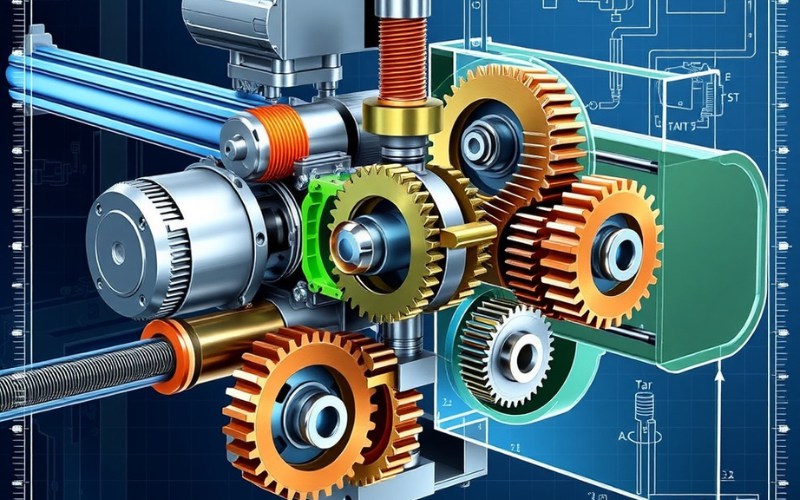

In this post, I want to share what I’ve found out with you. We will look at the main parts of a CNC machine. We’ll go from the strong bottom part to the smart computer that runs it all. Think of this as a look inside one of the most important machines used today. When we are done, you will have a clear idea of how these machine pieces work as a team. You will know what each part does in the CNC block diagram. This information is for you if you have ever wondered how CNC machines turn ideas into real objects.

A CNC machine stands for Computer Numerical Control. It is a machine that uses a computer to guide its tools. You can think of it as a robot that you can instruct on what to create. These CNC machines are very key for making many kinds of items, from car parts to phone cases. They are great at making very exact parts that have to be just right. Knowing the parts of a CNC machine is the best way to understand how it works so well. Every part of the CNC machine has a specific task. When all the pieces work together, the machine can build wonderful things.

The reason it is so important to understand the machine’s pieces is that it helps you see the big picture. It is like knowing the different parts of a car’s engine. Once you know what the pistons and spark plugs do, you get how the car moves. It is the same idea with CNC machines. When you learn about the machine control unit, the drive system, and the cutting tool, you will see how a block of metal turns into a part that is finished. This guide to the components will help you see how all the machine parts join together in the making process.

Every big building must have a strong base, and a CNC machine is the same way. The machine bed is the foundation that holds up everything else. It is a very heavy and solid part of the machine. It is often made of cast iron. This is because it has to be very still and steady. While the machine is working, there can be a lot of shaking. The heavy machine bed takes in this shaking. This makes sure that the machine is stable and can make very accurate cuts. Without a strong base, the whole machine would move around. Then, it would be impossible to make exact parts.

The machine bed is not just a heavy block. It is the part of the CNC machine that holds up all the other pieces. The tracks for the different axes are put on the bed. The worktable, which is where the workpiece is held, also rests on the bed. The column that holds the spindle is also attached to the bed. So, you can see that the machine bed is the first piece for building a strong and correct machine. It is a major part of what makes CNC machines so good at what they do. A great machine begins with a great base.

If the machine bed is the base, then the Machine Control Unit (MCU) is the brain of the CNC machine. This is the place where all the “thinking” is done. The MCU is a small computer inside the machine. Its job is to read the CNC program. The program is a list of commands that tell the machine how to act. The MCU reads these commands. It then changes them into electric signals that guide the machine’s movements. It is the part of the machine that makes sure every step happens in the correct order and at the correct time.

The machine control unit has a very important job. It needs to read the program. It must plan the path for the cutting tool. It also has to manage the speed of the motors. It is what makes the magic of computer numerical control happen. Inside the MCU, there are strong electronics that can do all of this very fast. This lets the machine make movements that are smooth and exact. A CNC machine without the MCU would be just a pile of machine parts. The MCU is the part that makes the machine come alive and gives it the power to create.

So, we have the brain of the machine, which is the MCU. But how do we give it the commands? That is the job of input devices. An input device is the way the person running the machine can put the CNC program into it. A long time ago, this was done with things like paper cards with holes. Today, we use newer ways. The most common input device is a computer that is hooked up to the CNC machine. The operator can type the program on the computer. Then, they can send it right to the machine.

The control panel is another key input device. The control panel lets operators work with the machine face-to-face. It has buttons, switches, and a screen. The screen is a display unit. It shows the operator what the machine is currently doing. The operator can use the control panel to start and stop the machine. They can also change the speed of the spindle or move the cutting tool by hand. The control panel is a very key part of the machine for the operator. It is the main way to talk with the machine and direct its work. The control panel and other input devices are the link between the person and the machine control unit.

The MCU gives the commands, but another part has to do the moving. That is the task of the drive system. The drive system is built from a few parts that team up to move the machine parts. The main pieces of the drive system are the motors, amplifiers, and ball screws. The motors give the power to move the machine’s different axes. The amplifiers receive the small electric signals from the MCU. They make those signals strong enough to run the motors.

There are two main kinds of motors used in CNC machines: stepper motors and servo motors. Servo motors are usually found in more costly machines. This is because they are more exact. The drive system also has ball screws. A screw is a simple tool that can change spinning motion into motion in a straight line. The motors spin the ball screws. This action moves the worktable and the cutting tool along the axes. The drive system is what gives the CNC machine the power to move with great accuracy. The quality of the drive system really affects how correct the whole machine is.

A CNC machine must know the exact spot of the cutting tool and the workpiece all the time. This is where the feedback system helps. The feedback system is like the machine’s own sense of touch. It reports to the MCU the precise location of the machine’s moving parts. This is very important for creating correct parts. If the machine does not know its location, it cannot make exact cuts. The feedback system makes sure that the machine is always where it should be.

The main parts of the feedback system are sensors and encoders. These items are attached to the moving parts of the machine. They always send signals back to the MCU. These signals carry information about the location and speed of the axes. The MCU then checks this information against the commands in the CNC program. If it finds a difference, the MCU can fix it. This is known as a closed-loop system. It is what lets CNC machines be so amazingly accurate. The feedback system is a vital part of the cnc system that promises good quality.

Now we are at the part of the machine that does the hard work: the spindle and the cutting tool. The spindle is a shaft that spins and holds the cutting tool. It gets its power from a motor that can make it turn at very high speeds. The MCU can control the speed of the spindle. Different kinds of materials and different cutting jobs need different spindle speeds. A strong and exact spindle is a very key part of any CNC machine.

The cutting tool is the piece of the machine that physically cuts away the material from the workpiece. There is a wide variety of cutting tools for many different tasks. For a cnc mill, you might use a tool called an end mill to cut grooves or a drill to create holes. For cnc turning on a cnc lathe, you would use another kind of cutting tool to make round parts. The cutting tool is held very securely in the spindle. The fast-spinning spindle and the sharp cutting tool work together. This combination lets the machine shape the workpiece.

You cannot cut an object if it is wiggling around. This is why the worktable and fixtures are so needed. The worktable is the flat area where you mount the workpiece. It is typically made from cast iron and has T-shaped grooves cut into it. People use these grooves to bolt the workpiece down so it is secure. The worktable is the part of the machine that moves on the X and Y axes. It carries the workpiece along with it.

Fixtures are special tools used to hold the workpiece in one specific spot on the worktable. For some easy parts, a simple clamp called a vise might be enough. For parts with more complex shapes, a special, custom fixture might be made. The purpose of the fixture is to hold the workpiece very tightly. This stops it from moving while the machine is working. A good fixture is a must for making correct parts. The worktable and fixtures are key pieces that make sure the workpiece stays in the right spot for the cutting tool to do its work.

There are many kinds of CNC machines. Each type has some special machine parts. Some of the most common kinds of cnc machines are milling machines, lathes, and routers. A cnc mill is a machine that uses a spinning cutting tool. It removes material from a workpiece that stays still. CNC lathes are used for cnc turning jobs. In this case, the workpiece spins and the cutting tool stays still. CNC routers are like milling machines. But, they are often used for cutting materials that are softer, like wood and plastic.

Even though the main parts are the same, there are a few differences. For instance, a cnc lathe will have a part called a chuck to hold the spinning workpiece. You will not see a chuck on a cnc mill. More complex machines, like 5-axis cnc machines, have more ways to move. This lets them make very complicated shapes. An advanced 5-axis machine can move the tool along five different paths at the same time. No matter what kind of cnc machine it is, knowing the main parts of a cnc machine is the first step to see how it works. Each kind of machine is made for a certain job, but they all use the same basic ideas of computer numerical control.

After learning about all the parts of a CNC machine, you may ask if you can make one yourself. The answer is yes! A lot of people build their own custom cnc machines. It can be a project that makes you feel very proud. You can purchase kits that include all the machine parts you need. Or, you can find and buy the pieces on your own. Building a custom cnc machine lets you pick the size and the features of your machine.

If you choose to build a custom cnc machine, you will have to pick all the pieces we have discussed very carefully. You will need a strong machine bed. You’ll need a good drive system that has strong motors. You will also need an accurate feedback system. You will also have to select a machine control unit and an input device. There are many free, open-source choices for the control unit. Making a custom cnc machine is a wonderful way to learn even more about how these amazing machines operate. It is a big project, but it can also be a lot of fun.

As we have learned, CNC machines are built from many key parts that work as a team. Here are the most important things to remember from our guide on the components: