Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

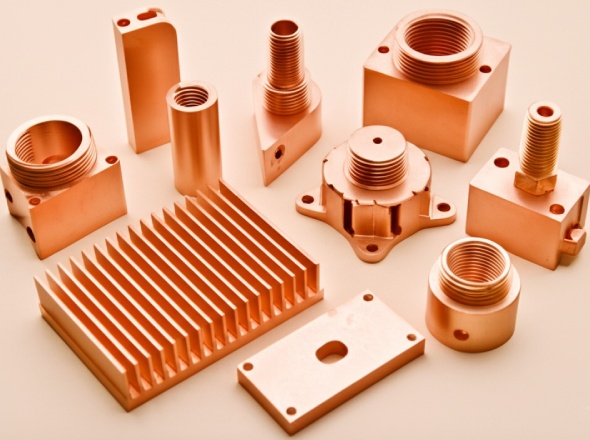

Copper CNC machining is a way to make parts from copper using computer-controlled tools. At Istar Machining, we use high-tech machines to cut, shape, and finish copper into exactly what you need. Our machines follow computer instructions to make perfect parts every time.

Copper is a soft, reddish-brown metal that works great for many jobs. It’s one of the best metals for moving heat and electricity, which is why it’s used in so many important things. From simple parts to complex shapes, we can make exactly what you need with our advanced CNC (Computer Numerical Control) tools.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Copper has some special powers that make it perfect for many jobs:

At Istar Machining, we work with several grades of copper, including C101, C110, and C360. Each type has special qualities for different jobs. We’ll help you pick the right one for your project.

Learn more about our CNC machining service for all materials we work with.

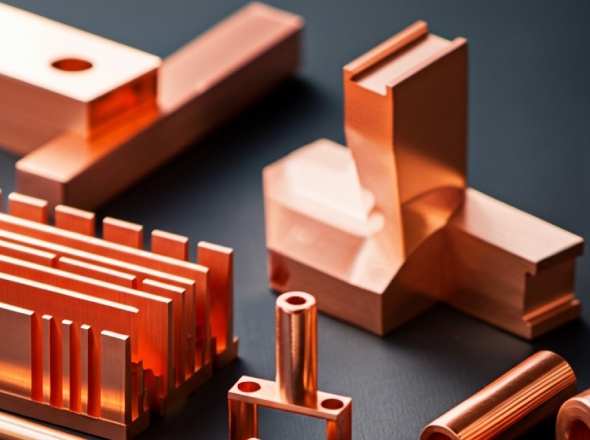

Our shop has the most advanced equipment to work with copper in many ways. Here’s what we can do:

Machining Process | What We Can Do | Benefits |

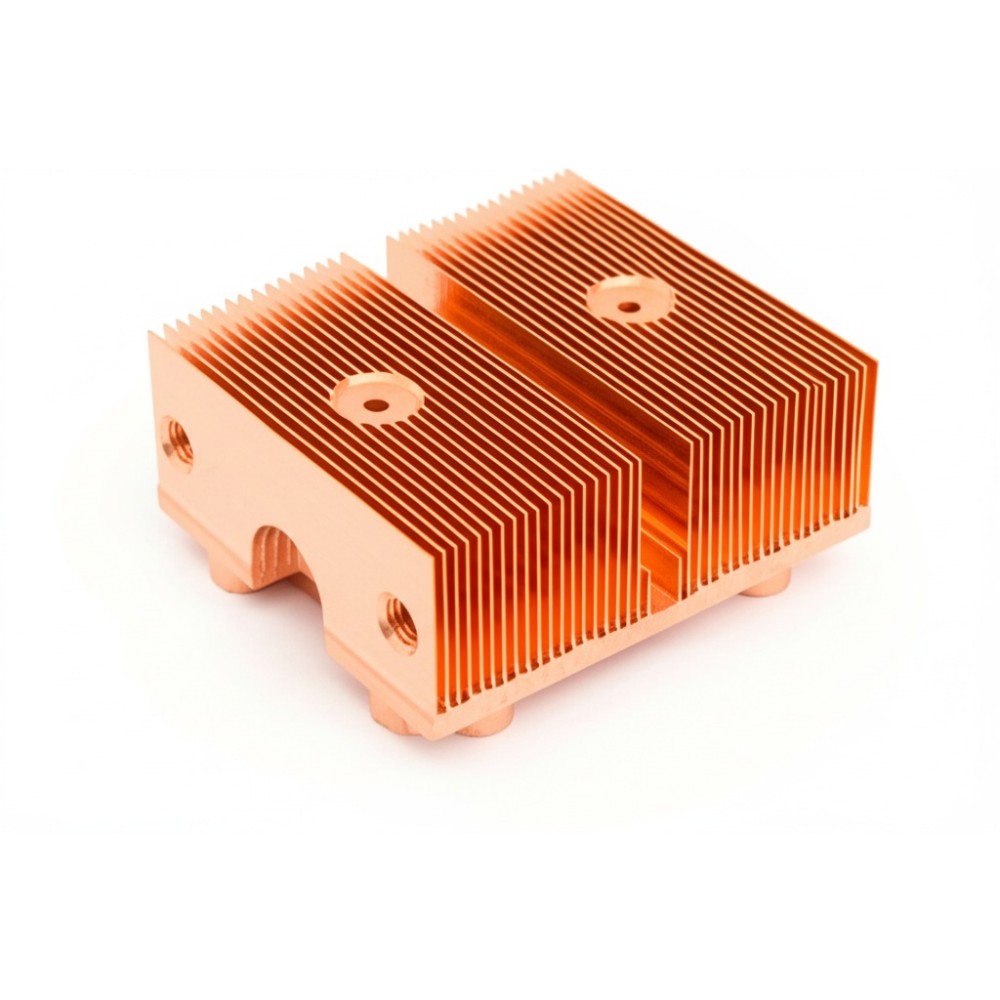

5-axis milling | Complex 3D shapes with undercuts | Perfect for intricate parts like waveguides |

CNC turning | Round parts with tight tolerances | Ideal for bushings, connectors, fittings |

EDM machining | Ultra-precise cuts and shapes | Great for small, detailed components |

Surface finishing | Polishing, plating, annealing | Enhanced performance and appearance |

Precision tolerances | Down to ±0.001″ (0.025mm) | Ensures perfect fit and function |

Surface finishes | 8-32 µin Ra | From mirror smooth to textured as needed |

Need both milling and turning? Check out our multi-axis turning capabilities for complex parts that need both cutting methods.

We can make copper parts up to 300mm x 300mm x 150mm (about 12″ x 12″ x 6″).

For extremely precise work, our sinker EDM machining is perfect for copper parts that need super sharp corners or tiny details.

Copper parts are used in many important industries. Here are some ways our customers use our copper machining services:

At Istar Machining, we use different types of copper depending on what you need:

C101 (Oxygen-Free Copper)

C110 (ETP Copper)

C360 (Free-Cutting Brass)

For applications that need both copper’s properties and better machinability, check out our brass CNC machining services.

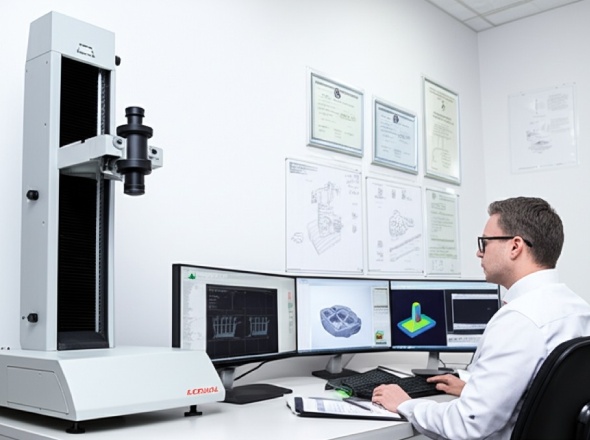

At Istar Machining, we ensure every part meets or exceeds specifications:

When you choose Istar Machining for your copper CNC needs, you get:

(Design for Manufacturing) analysis

times, even for rush orders

without sacrificing quality

with decades of experience

with every order

Here’s how we turn raw copper into perfect parts at Istar Machining:

We look at your blueprints and suggest improvements to save money and time.

Our engineers create toolpaths for our CNC machines.

Our computer-controlled machines cut and shape the copper.

We can add finishes like polishing, plating, or annealing as needed.

We perform a comprehensive check before shipping.

Ready to start your copper CNC project? Contact Istar Machining today for:

Visit our contact page to get started.

For complex precision projects, visit our precision CNC machining page to learn more about our high-precision capabilities.

Istar Machining is your trusted partner for precision copper CNC machining. From prototypes to production runs, we deliver quality, precision, and value on every project.

C101 (Oxygen-Free Copper) is ideal for electrical applications requiring maximum conductivity. It’s 99.99% pure copper with no oxygen content.

Yes! Our 5-axis machines and EDM capabilities allow us to create very complex shapes with tight tolerances. We can produce sharp corners, thin walls, and intricate details in copper.

We can deliver simple prototypes in as fast as 24 hours. More complex parts typically take 3-5 days. Production runs usually require 5-10 days depending on quantity and complexity.

While copper material costs more than some metals, its excellent machinability often means lower overall production costs. We’ll help you optimize your design to keep costs down.

Absolutely! Copper naturally develops a protective patina outdoors that actually enhances its corrosion resistance. It’s excellent for outdoor applications.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or