Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for super light parts that are also strong? Magnesium CNC machining might be just what you need! At Istar Machining, we use special computer-controlled tools to shape magnesium into amazing parts. Let’s learn all about this cool metal and how we turn it into exactly what you need!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

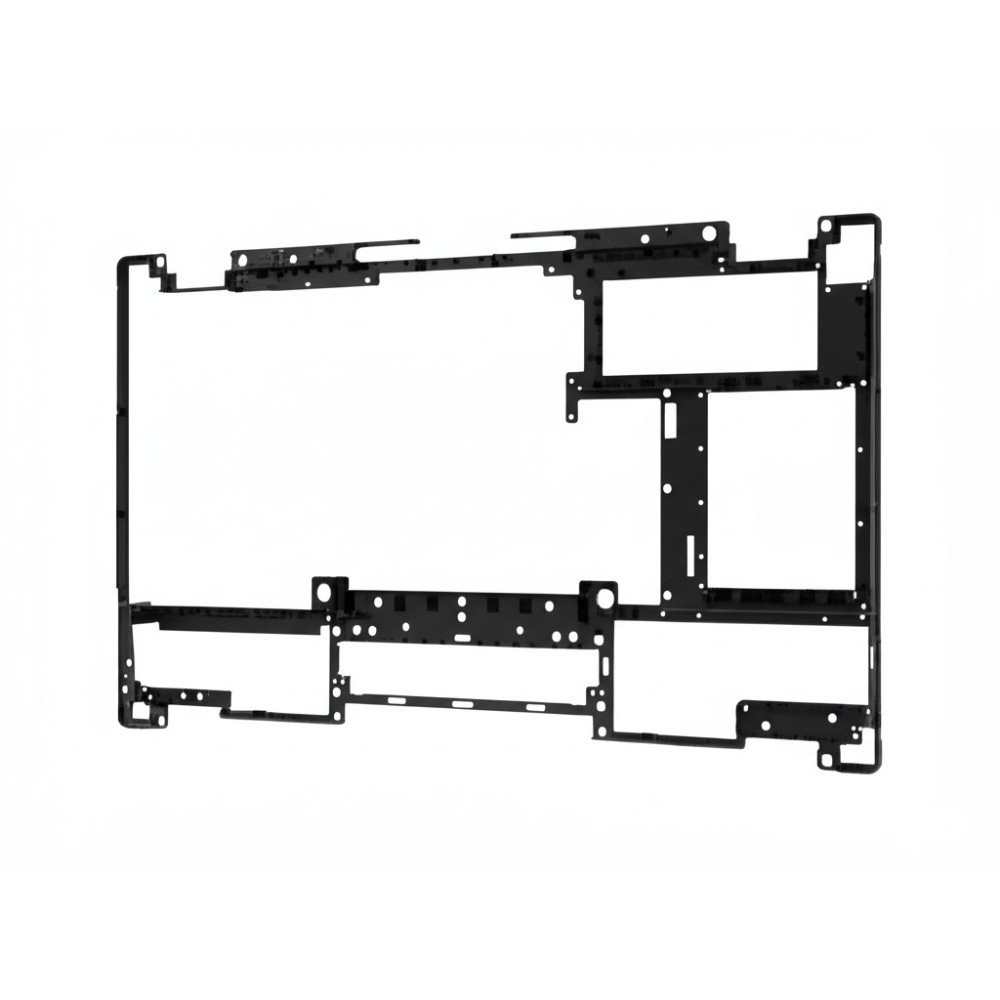

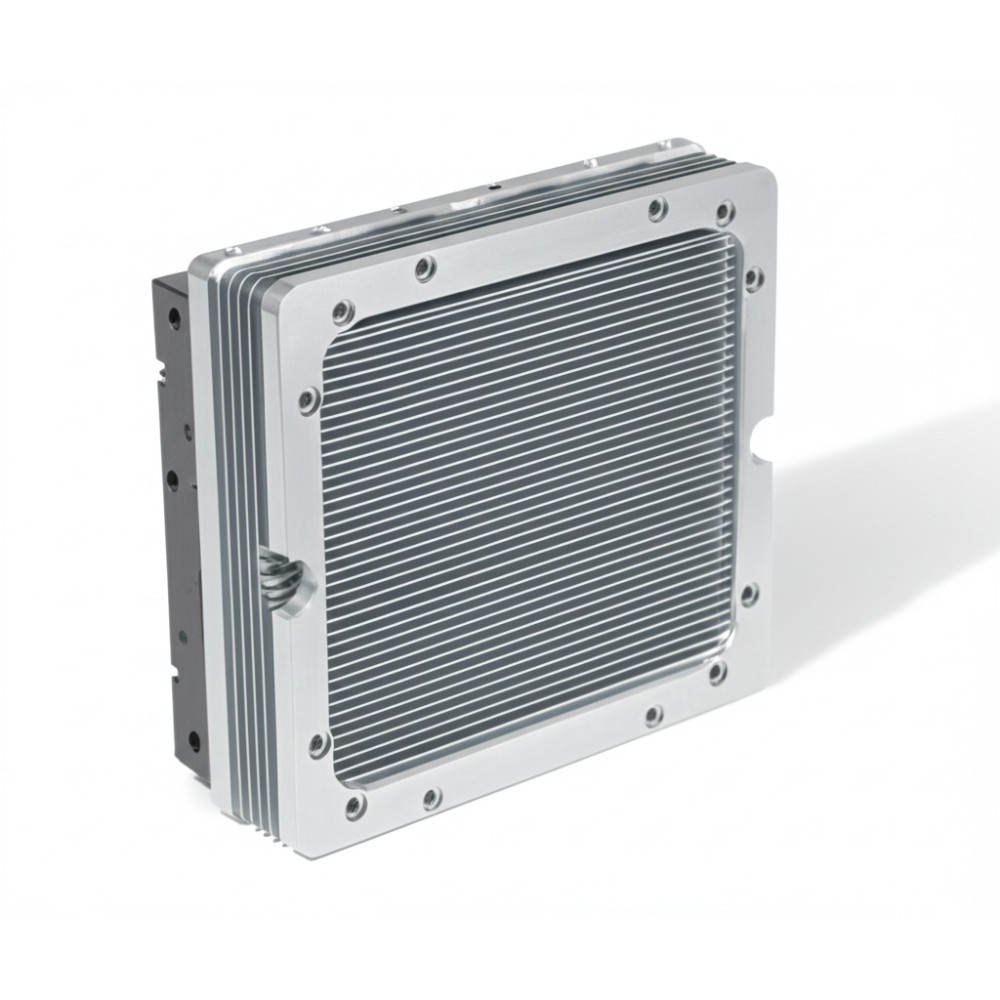

At Istar Machining, we can make magnesium parts with amazing accuracy:

Our precision CNC machining services ensure your magnesium parts will fit perfectly every time.

Material Grade | Best For | Key Properties |

AZ31B | Automotive parts, electronics | Good strength, excellent formability |

AZ91D | Aerospace components | High strength, good corrosion resistance |

AM60 | Complex parts with thin walls | Excellent ductility and impact resistance |

ZK60A | High-performance applications | Superior strength and hardness |

WE43 | Medical devices | Biocompatible, high heat resistance |

Feature | Magnesium | Aluminum | Titanium | Steel | Plastic |

Density | Very Low | Low | Medium | High | Very Low |

Strength | Good | Good | Excellent | Excellent | Poor |

Heat Conductivity | Excellent | Excellent | Poor | Poor | Very Poor |

Cost | Medium | Low | High | Low | Very Low |

Machinability | Excellent | Excellent | Difficult | Good | Excellent |

Corrosion Resistance | Poor (needs coating) | Good | Excellent | Variable | Excellent |

Weight Savings | Best | Good | Medium | Poor | Best |

Magnesium is awesome, but it needs special care when machining:

At Istar Machining, our experts know all these challenges and have solved them. We have special systems to keep magnesium machining safe and effective.

We’re not just another machine shop. Here’s why customers choose our CNC machining service:

with years of experience

processes for flammable materials

from design help to finished parts

times for urgent projects

without sacrificing quality

with our closed-loop recycling

We use 5-axis machining technology to create complex magnesium parts with amazing precision. Our experts know all the special tricks needed to work with magnesium safely and effectively.

We look at your designs to make sure they'll work well

We create special instructions for our machines

We use special tools and safety systems

We make sure every part meets exact specifications

We can add coatings to protect against corrosion

Contact Istar Machining today to discuss how our magnesium CNC machining services can help you create lighter, stronger parts for your applications. Our team is ready to answer your questions and provide a free quote for your project.

Email: [email protected] Website: istarmachining.com

Let us show you the magic of magnesium and how it can transform your products!

A: Yes! When properly machined and treated with protective coatings, magnesium is safe for most applications.

A: We apply special surface treatments like anodizing, chromate conversion coatings, or paint finishes.

A: Yes! Magnesium is about 33% lighter than aluminum and 75% lighter than steel.

A: Absolutely! Our 5-axis machining technology can create incredibly complex magnesium parts.

A: We can machine magnesium parts with walls as thin as 0.5mm and as thick as 50mm or more.

A: It can be slightly more expensive due to safety requirements, but the weight savings often justify the small cost difference.

A: We can create surface finishes from Ra 0.8 to 3.2 μm, including mirror-polished finishes.

A: Simple parts can be made in just a few days, while complex components might take 1-2 weeks, depending on specifications.

If you care more about appearance, corrosion margin and extrusion-friendly shapes, 6063-T52 usually wins. If you care more about structural

If you work in construction, fabrication, CNC machining, product design, or procurement, you’ve probably hit this exact moment: “The drawing

You almost never choose between a bearing and a bushing because of friction alone. You choose because of how you