Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

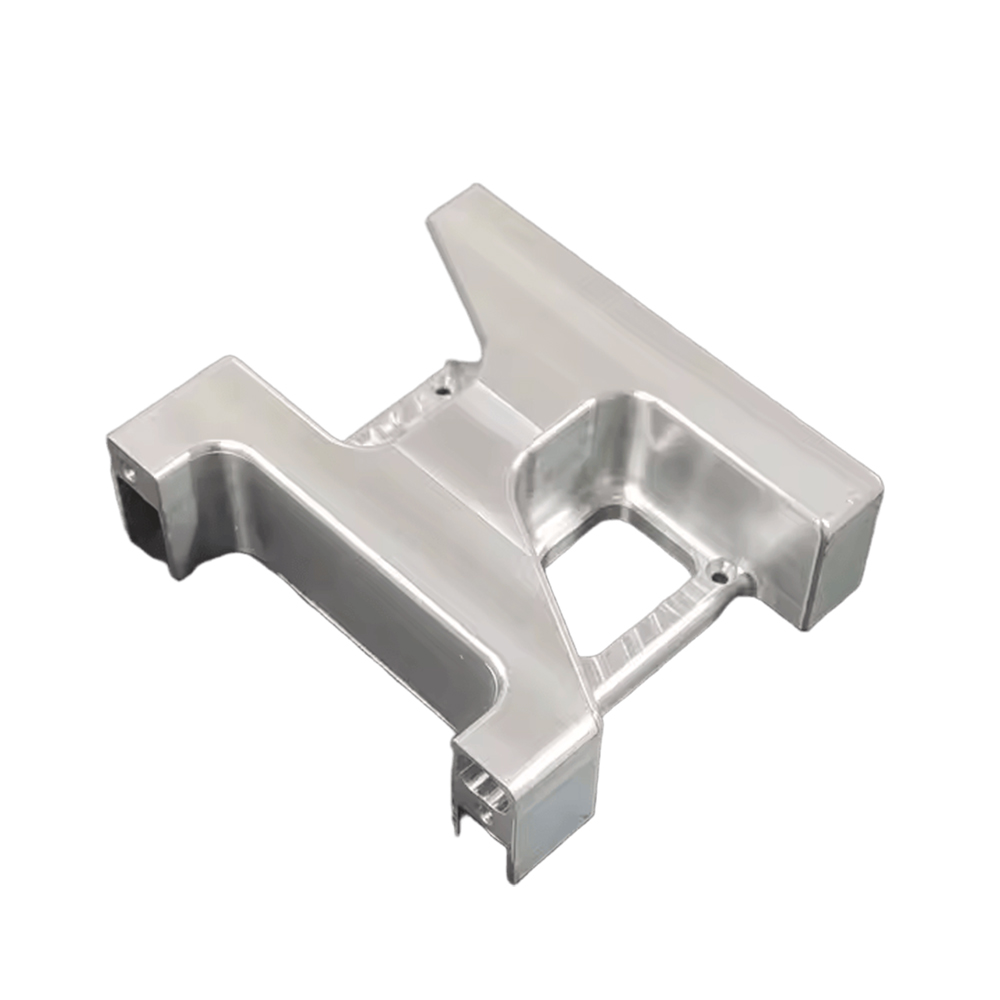

Welcome to the world of high-precision manufacturing! At Istar Machining, we turn your designs into real, working parts with our top-notch CNC machining service. Our machines use computer control to make parts that fit just right – every time!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Our CNC machining service provides high-precision, efficient custom parts manufacturing solutions. With advanced equipment and a professional team, we ensure every project meets the highest quality standards.

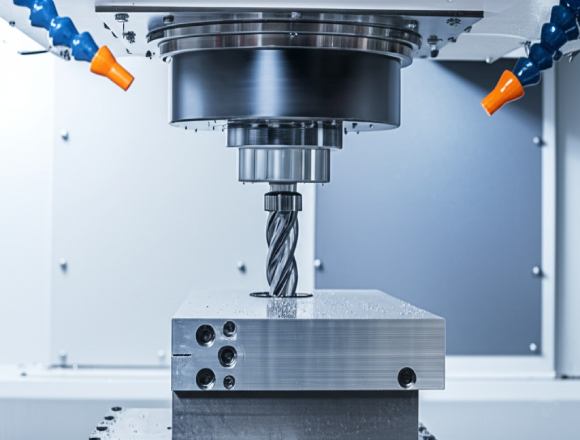

CNC milling technology precisely removes material to create complex 3D shapes and intricate features. Our multi-axis milling equipment can process various metals and plastics, achieving accuracy within ±0.0001mm.

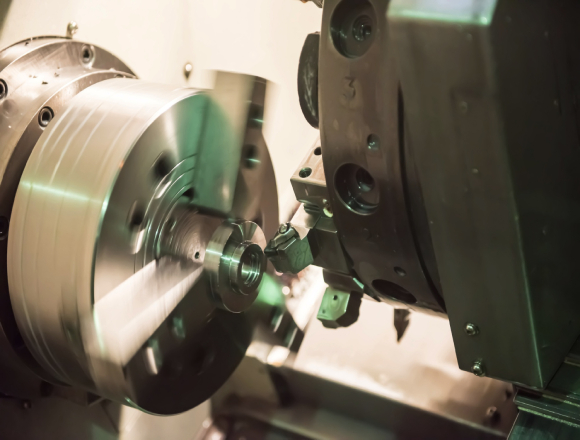

CNC turning is designed for rotationally symmetric parts, utilizing high-speed workpiece rotation and precision cutting tools. Ideal for efficient production of shafts, bushings, and cylindrical components.

CNC routing excels at processing large sheets and thin materials, creating beautiful patterns and complex contours. Particularly suitable for precise machining of wood, plastic sheets, and composite materials.

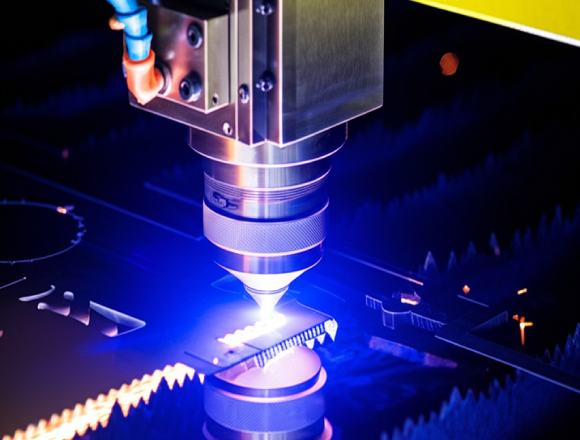

CNC cutting employs advanced laser or plasma technology, offering unmatched cutting precision and edge quality. Capable of high-speed processing of metal sheets in various thicknesses while minimizing material waste.

At Istar Machining, we can cut, shape, and finish many different materials:

Material Type | Examples | Good For |

Metals | Aluminum 6061-T6, Stainless Steel 316, Titanium Grade 5… | Airplane parts, car engines, medical implants |

Plastics | ABS, PEEK, Nylon… | Lightweight parts, clear components, flexible items |

Composites | Carbon fiber, G10… | Super-strong but light parts for racing cars and planes |

For special projects, our team at Istar Machining can help you pick the best material for your needs. Need something that won’t rust? Stainless steel CNC machining is perfect! Want something light but strong? Try our aluminum CNC machining!

Aluminum is popular because it’s:

Perfect for: Aerospace parts, electronics housings, automotive components

Stainless steel offers:

Perfect for: Food processing equipment, medical devices, outdoor applications

Titanium has many uses due to its properties:

Copper is also often chosen by customers as a material:

At Istar Machining, many customers choose other metals for CNC machining due to their application:

PTFE (also called Teflon) is super slippery. Nothing sticks to it!

Good for:

Why customers love it: “The PTFE parts from Istar Machining don’t react with any chemicals in our lab. They stay clean and last forever.”

Nylon is tough and doesn’t wear out fast. It bends a little but is still strong.

Good for:

Why customers love it: “The nylon rollers from Istar Machining work better than metal ones in our textile machines. They’re quiet and don’t damage the fabric.”

ABS is easy to work with and costs less. It’s good for testing ideas.

Good for:

Why customers love it: “Istar Machining helped us test our design in ABS first. It saved us money before we made the final product.”

Ultem won’t burn easily and can be cleaned with hot steam. It stays strong at high heat (340°F or 170°C).

Good for:

Why customers love it: “The Ultem parts from Istar Machining passed all our fire safety tests for our aircraft interiors. They met all the rules we have to follow.”

HDPE won’t soak up water and is safe for food. It’s easy to clean.

Good for:

Why customers love it: “Istar Machining made HDPE parts for our food processing equipment that are easy to clean and don’t wear out.”

Acrylic is clear like glass but lighter. It stays clear in the sun.

Good for:

Why customers love it: “The clear acrylic displays Istar Machining made for our products look so good in our store. Customers can see our products from all sides.”

PETG can be recycled and stands up to many chemicals. It’s good for the earth.

Good for:

Why customers love it: “We like that Istar Machining can make our parts in PETG. It’s strong enough for our medical devices but better for the planet.”

Need a test part fast? We can make your first prototype in just 3-5 days! This helps you:

Our CNC prototype machining service is perfect when you need just a few parts to try out your idea.

Once your design is perfect, we can make hundreds or thousands of parts with the same high quality. Our machines run day and night to deliver your order on time, every time.

Some parts have tricky shapes with curves and angles that are hard to make. Our 5-axis machining can reach all sides of your part to create these complex shapes in one setup!

A part isn’t complete until it looks and feels right. We offer many finishing options:

| Finish Type | What It Looks Like | How Smooth It Is | Best For | Works On | Cost |

| As-Machined | Tool marks show | Ra 3.2 μm | Quick jobs, parts inside machines | All metals | $ |

| Bead Blasting | Smooth, not shiny | Ra 1.6-3.2 μm | Phones, plane parts | Most metals | $$ |

| Anodizing Type II | Colored, smooth | Ra 1.6 μm | Parts that get wet | Aluminum only | $$ |

| Anodizing Type III | Hard, colored | Ra 1.6 μm | Parts that get bumped | Aluminum only | $$$ |

| Polishing | Super shiny | Ra <0.8 μm | Medical tools, food parts | Most metals | $$$ |

| Electropolishing | Mirror-like | Ra <0.8 μm | Hospital parts | Stainless steel | $$$ |

| Powder Coating | Thick, colored | Ra 1.6-3.2 μm | Outside parts | Most metals | $$ |

| Passivation | No change in look | No change | Parts that can’t rust | Stainless steel | $$ |

Table 1: Appearance & Smoothness

| Finish Type | What It Looks Like | How Smooth It Is |

|---|---|---|

| As-Machined | Tool marks show | Ra 3.2 μm |

| Bead Blasting | Smooth, not shiny | Ra 1.6-3.2 μm |

| Anodizing Type II | Colored, smooth | Ra 1.6 μm |

| Anodizing Type III | Hard, colored | Ra 1.6 μm |

| Polishing | Super shiny | Ra <0.8 μm |

| Electropolishing | Mirror-like | Ra <0.8 μm |

| Powder Coating | Thick, colored | Ra 1.6-3.2 μm |

| Passivation | No change in look | No change |

Table 2: Application & Material

| Finish Type | Best For | Works On |

|---|---|---|

| As-Machined | Quick jobs, parts inside machines | All metals |

| Bead Blasting | Phones, plane parts | Most metals |

| Anodizing Type II | Parts that get wet | Aluminum only |

| Anodizing Type III | Parts that get bumped | Aluminum only |

| Polishing | Medical tools, food parts | Most metals |

| Electropolishing | Hospital parts | Stainless steel |

| Powder Coating | Outside parts | Most metals |

| Passivation | Parts that can’t rust | Stainless steel |

Istar Machining helps companies in many different fields:

Here are some examples of what we make every day:

For those who love the specifics, here’s what our machines can do:

Our team has 20+ years making parts for companies around the world. We know how to solve tricky manufacturing problems!

We use the best CNC machines from brands like Haas and Mazak. Our CNC milling and CNC turning centers can make almost any shape you can imagine.

We keep your ideas private with strict security. Your competitors will never see your designs!

Quality doesn't have to cost too much. We offer competitive rates, especially for larger orders.

Getting parts made at Istar Machining is easy:

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

CNC machining is a way to make parts using computers to control cutting tools. The letters “CNC” stand for “Computer Numerical Control.” This means a computer guides the tools that cut away material to create your part. It’s like carving a statue, but with super-precise machines instead of hands!

Think of it as a smart robot that follows a map (your design) to cut metal, plastic, or other materials into exactly the shape you need.

A: Prototypes in 3-5 days, production runs in 2-4 weeks depending on complexity.

A: We work with STEP, IGES, SolidWorks, and many other CAD formats.

A: Yes! We ship to customers worldwide with tracking on all packages.

A: Absolutely! Our design team can create CAD files from your sketches or ideas.

A: We can make as few as one part for prototypes. There’s no minimum order!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or