Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

When you need parts made just right, CNC milling is the way to go. At Istar Machining, we make metal and plastic parts with special machines that follow computer instructions. These machines cut away material to make the exact shape you need.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

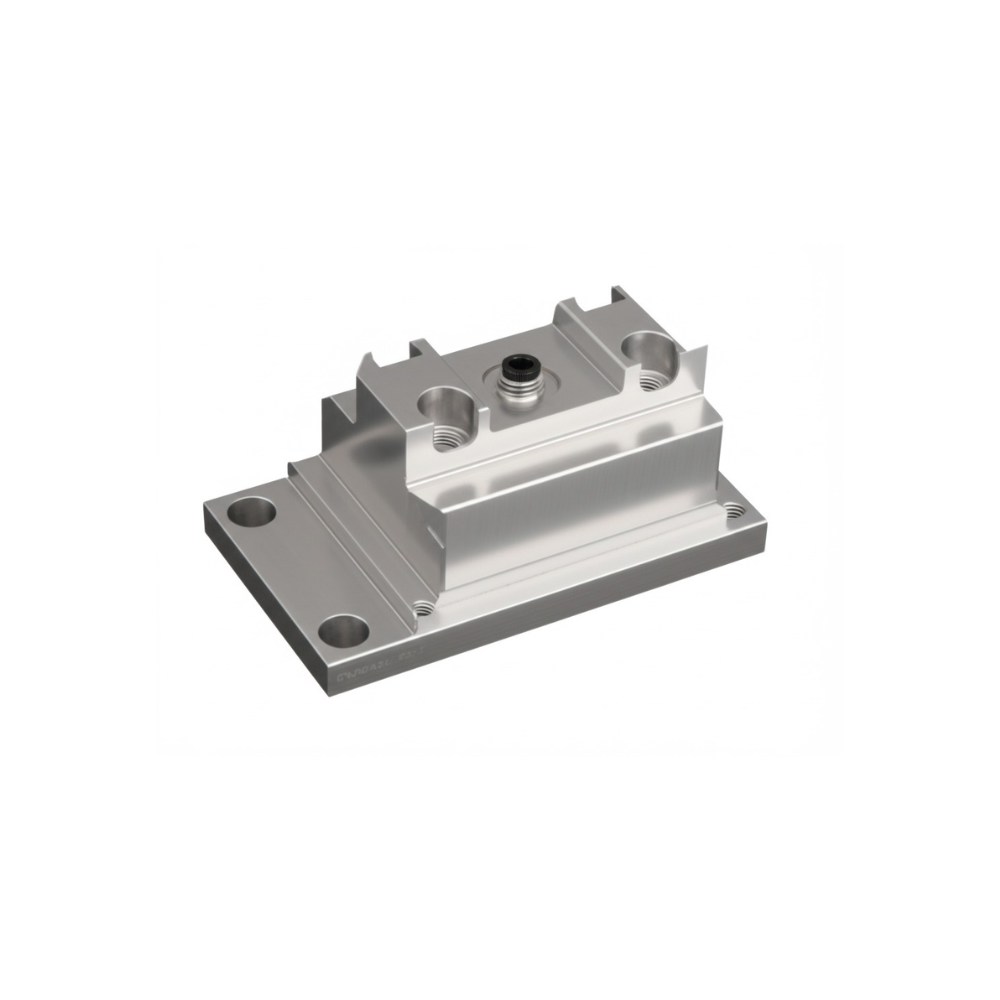

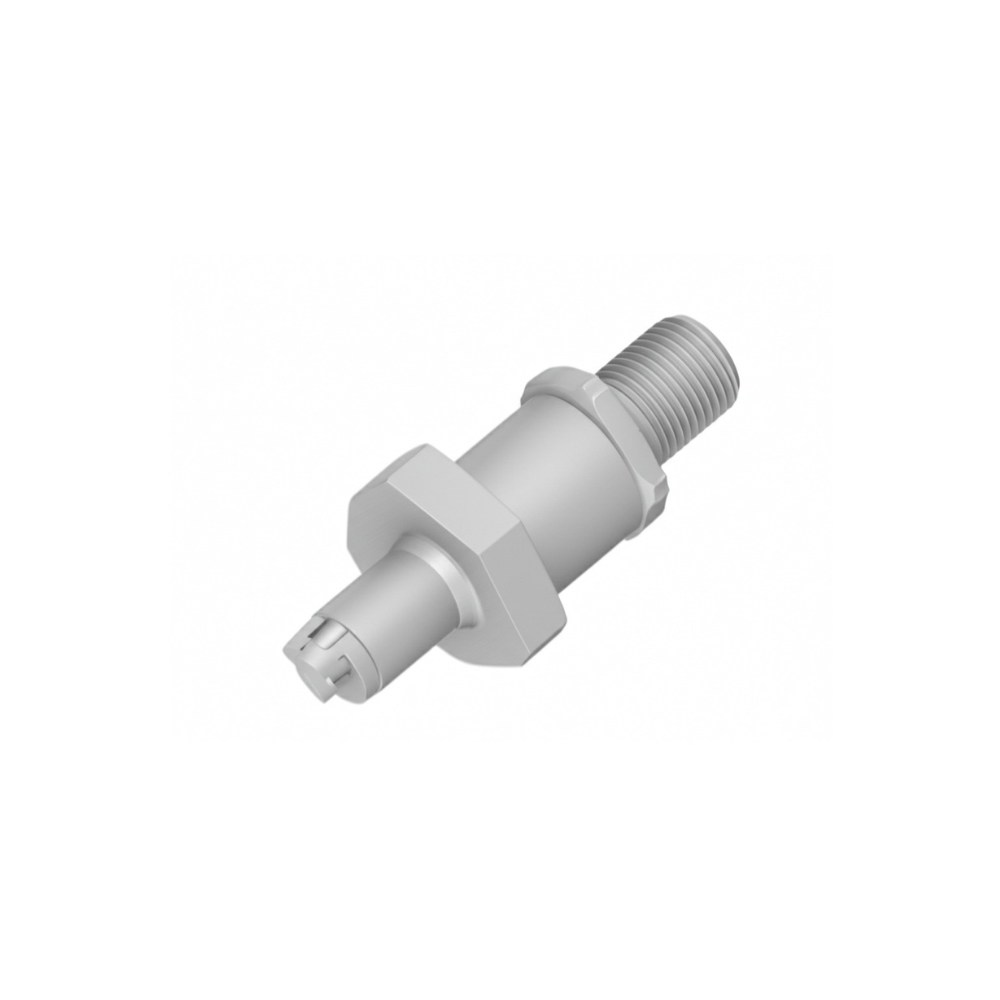

We can make all kinds of parts for different industries:

Here’s a table showing what our CNC milling machines can do:

Feature | What It Means For You | Why It Matters |

Fast Spindle (30,000 RPM) | Smooth cuts in tough materials | Your aerospace parts come out perfect |

Multi-Axis (3 to 5 Axis) | Can make complex shapes | Your car parts have all the curves they need |

Works With Many Materials | Can cut aluminum, steel, plastic | You can get parts in exactly what you need |

Very Accurate (±0.005 mm) | Parts fit together perfectly | Your medical devices work safely |

CAD/CAM Software | Turns your designs into real parts | Your ideas become real products faster |

Special Tools | Can use diamond-coated cutting tools | Your carbon fiber parts cut cleanly |

Strong Machine Frame | Less vibration means better finish | Your parts look and feel professional |

Flexible Production | Can make 1 or 1,000 parts | Start with a prototype, then order more |

Quick Delivery | Prototypes in 3 days | Get your test parts fast |

Surface Finish Options | From mirror smooth to textured | Your parts feel and look right |

Our CNC mills use spinning cutting tools to shape your parts. Think of it like a very precise drill that can move in many directions. The computer tells the tool exactly where to go.

Different materials are better for different jobs. Here’s what works best:

Metals

Aluminum (Common Grades: 6061, 7075, 5052, 2024) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

Stainless Steel (Common Grades: 303, 304, 316/316L, 416, 17-4 PH) offers high strength, excellent corrosion resistance, heat resistance, and durability. Machinability varies significantly by grade (303 is easiest).

Good for:

Why customers love it: “Its superior corrosion resistance, strength, durability, and aesthetic appeal make it ideal for demanding applications and harsh environments.”

Mild Steel / Carbon Steel (Common Grades: 1018, 1045, A36) is strong, tough, easily weldable, and relatively inexpensive. It requires protective coating (painting, plating) to prevent rust.

Good for:

Why customers love it: “It’s a cost-effective workhorse material offering good strength, versatility, and ease of fabrication, especially welding.”

Alloy Steel (Common Grades: 4140, 4340) is steel alloyed with elements like chromium, molybdenum, nickel, etc., to enhance properties like hardness, strength, toughness, wear resistance, or heat resistance.

Good for:

Why customers love it: “Offers tailored mechanical properties like superior strength, toughness, and wear resistance for demanding, high-performance applications.”

Brass (Common Grades: C360 – Free Machining Brass) is a copper-zinc alloy known for its exceptional machinability, good corrosion resistance, electrical conductivity, and attractive gold-like appearance.

Good for:

Why customers love it: “It’s incredibly easy and fast to machine, producing excellent surface finishes, making it cost-effective for intricate parts while offering good corrosion resistance.”

Titanium (Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) boasts an exceptional strength-to-weight ratio, outstanding corrosion resistance (especially to saltwater and chemicals), and biocompatibility. It is more challenging and costly to machine than steel or aluminum.

Good for:

Why customers love it: “Its unmatched strength-to-weight ratio, incredible corrosion resistance, and biocompatibility are critical for high-stakes aerospace, medical, and performance applications.”

Copper (Common Grades: C101 – OFE, C110 – ETP) offers unparalleled electrical and thermal conductivity, good corrosion resistance, and antimicrobial properties. It is relatively soft and can be somewhat ‘gummy’ to machine cleanly.

Good for:

Why customers love it: “Its superior electrical and thermal conductivity is essential for applications involving efficient transfer of electricity or heat.”

Plastics

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its toughness, impact resistance, rigidity, and ease of machining. It’s relatively low-cost and available in various colors.

Good for:

Why customers love it: “Provides a great all-around balance of toughness, rigidity, impact resistance, and cost-effectiveness for many general-purpose applications.”

Nylon (PA) (Common Grades: Nylon 6, Nylon 6/6) is a strong, tough engineering thermoplastic with excellent wear resistance, low friction properties, and good chemical resistance. It can absorb moisture, which may affect dimensional stability.

Good for:

Why customers love it: “Its combination of high strength, toughness, and excellent wear and abrasion resistance makes it ideal for moving parts and high-friction applications.”

Polycarbonate (PC) is an extremely durable, high-impact resistant thermoplastic with excellent toughness and optical clarity (in clear grades). It maintains properties over a wide temperature range.

Good for:

Why customers love it: “Offers exceptional impact resistance and toughness, often described as ‘virtually unbreakable’, along with good clarity and temperature resistance.”

Acetal (POM / Delrin®) is an engineering thermoplastic characterized by its high stiffness, low friction, excellent dimensional stability, good wear resistance, and resistance to moisture and chemicals. It machines beautifully to tight tolerances.

Good for:

Why customers love it: “Its excellent machinability, high stiffness, low friction, and superb dimensional stability make it a top choice for precision mechanical components.”

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic offering exceptional mechanical strength, high-temperature resistance (continuous use up to ~250°C / 480°F), excellent chemical resistance, and wear resistance. Biocompatible grades are available. It is more expensive and requires care in machining.

Good for:

Why customers love it: “Delivers outstanding performance in extreme conditions – high temperature, harsh chemicals, high mechanical stress – where other plastics fail.”

Acrylic (PMMA / Plexiglas® / Lucite®) is a rigid thermoplastic known for its excellent optical clarity, weather resistance, and UV stability. It’s more brittle than Polycarbonate but easier to polish to a high gloss.

Good for:

Why customers love it: “Offers glass-like clarity and excellent weatherability at a lower cost and weight than glass, and is easier to fabricate.”

UHMW PE (Ultra-High Molecular Weight Polyethylene) is known for its extremely high abrasion resistance, low coefficient of friction, high impact strength, and good chemical resistance. It can be challenging to machine to tight tolerances due to its nature.

Good for:

Why customers love it: “Its outstanding abrasion resistance and impact strength make it incredibly durable in high-wear, sliding contact applications.”

Composites & Other Materials

Garolite (G-10 / FR-4) is a high-pressure thermoset laminate made of woven glass fabric and epoxy resin. It offers high strength, low moisture absorption, excellent electrical insulating properties, and good dimensional stability. It is abrasive to machine.

Good for:

Why customers love it: “Provides a strong, stable, and electrically insulating material suitable for demanding mechanical and electrical applications.”

Carbon Fiber Reinforced Polymer (CFRP) consists of strong carbon fibers embedded in a polymer matrix (typically epoxy). It offers extremely high stiffness-to-weight and strength-to-weight ratios. Machining requires specialized tooling, dust extraction, and techniques due to its abrasive and delaminating nature. (Note: Mention if your service specifically handles this well).

Good for:

Why customers love it: “Offers unparalleled stiffness and strength for its weight, enabling lightweight and high-performance designs.”

When making parts for planes and spacecraft, mistakes aren’t an option. Our toolpath optimization ensures every cut is perfect. We follow strict GD&T standards and have all the right certifications.

Medical parts need special care. Our medical CNC machining services make parts with the right surface finish and tolerance for safe use in the human body.

Car parts need to be tough and reliable. Our machines can handle everything from engine blocks to custom racing parts. We use special feed rates for different metals to get the best strength.

Send us your design file (CAD drawing)

We'll check if it can be made and give you a price

After you approve, we start making your parts

We check every part to make sure it's perfect

We ship the parts to you, ready to use

Ready to turn your ideas into real parts? Contact us for a free quote and CAD file review. We guarantee 99% on-time delivery.

Yes! We use special carbide tools that can cut even the hardest steels.

Absolutely! We make as few as 1 part for testing, or up to 10,000 for production.

Our machines can hold tolerances as tight as 0.005mm, which is about 1/5 the width of a human hair!

Yes, our 5-axis machining center can reach inside parts to create internal features.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or