Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

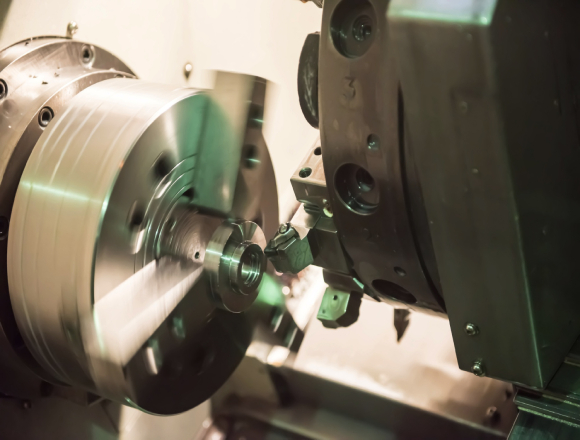

Are you looking for high-quality machine parts that are made with great care? CNC turned parts might be just what you need! These special parts are made by machines that spin metal or other materials to create perfect cylinders, cones, and other round shapes. At Istar Machining, we make these parts with super careful work and the best machines around.

Let’s learn all about CNC turned parts and how they can help your projects!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

For parts that need extra special care, we offer:

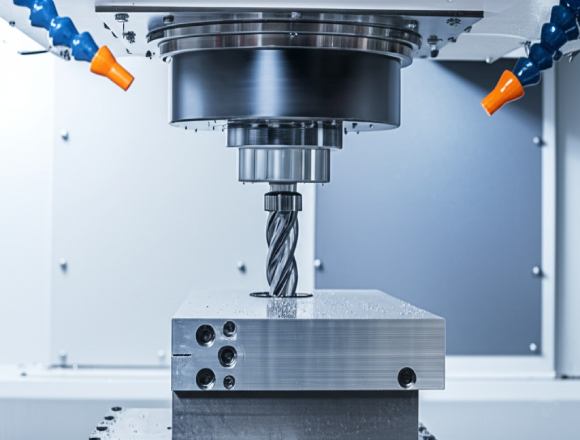

With our multi-axis turning machines, we can make complex parts in one setup that would normally need multiple machines.

Our Swiss turning machines are perfect for very small, precise parts. They support the material close to where cutting happens, making super accurate tiny parts.

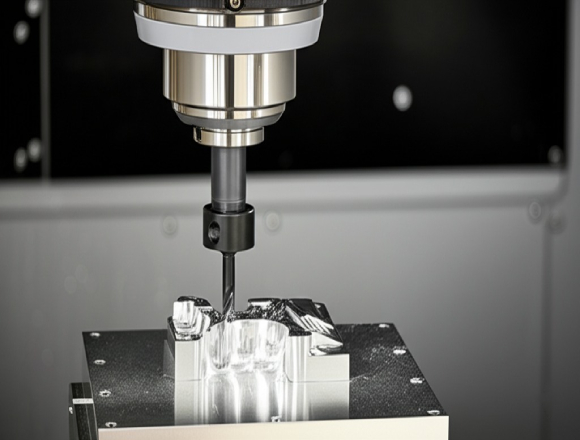

Our lathes with live tooling can do both turning and milling without moving the part to another machine. This saves time and makes better parts.

We can turn hardened materials that many shops can't handle. This can replace grinding in some cases, saving you money.

Our CNC turned parts are used in many different fields:

At Istar Machining, we can work with almost any material you need. Here are some common ones:

Metals

Lightweight, excellent machinability, high strength-to-weight ratio, and good corrosion resistance. Ideal for aerospace, automotive, and consumer electronics.

Common Grades We Turn:

6061: Versatile, good strength, weldability, and corrosion resistance.

7075: High strength, often used in aerospace and high-stress applications.

2024: High strength, good fatigue resistance, commonly used in aircraft structures.

5052: Excellent corrosion resistance (especially saltwater), good formability.

MIC-6: Cast tool plate, known for stability and flatness.

Versatile, strong, and cost-effective. Suitable for a wide range of structural and mechanical applications.

Common Types & Grades We Turn:

Carbon Steel (e.g., 1018, 1045): General purpose, varying hardness and strength.

Alloy Steel (e.g., 4140, 4340): Enhanced properties (hardness, toughness) through alloying elements.

Free-Machining Steel (e.g., 12L14): Excellent machinability due to lead/sulfur additions, ideal for high-volume production.

Known for exceptional corrosion resistance, strength, and aesthetic appeal. Widely used in medical, food processing, and marine applications.

Common Grades We Turn:

303: Free-machining version of 304, good corrosion resistance.

304/304L: Most common grade, excellent corrosion resistance, good formability.

316/316L: Enhanced corrosion resistance (especially against chlorides), marine grade.

416: Free-machining, heat-treatable martensitic stainless steel.

17-4 PH: Precipitation-hardening, high strength and hardness, good corrosion resistance.

Excellent machinability (“the standard”), good corrosion resistance, electrically conductive, and attractive appearance. Often used for fittings, valves, and decorative parts.

Common Grades We Turn:

C360 (Free-Cutting Brass): Highly machinable, standard for screw machine products.

C260 (Cartridge Brass): Good cold working properties.

Outstanding electrical and thermal conductivity, good corrosion resistance, and machinability (though gummy).

Common Grades We Turn:

C101 (OFHC – Oxygen-Free High Conductivity): Highest purity and conductivity.

C110 (ETP – Electrolytic Tough Pitch): Most common grade, excellent conductivity.

Known for good wear resistance, fatigue strength, and corrosion resistance, often used in bearings, bushings, and marine hardware.

Common Grades We Turn:

C932 (SAE 660 Bearing Bronze): Excellent machinability and anti-friction properties.

C630 (Nickel Aluminum Bronze): High strength, excellent corrosion and wear resistance.

High strength-to-weight ratio, excellent corrosion resistance (especially in harsh environments), and biocompatibility. Used in aerospace, medical implants, and chemical processing.

Common Grades We Turn:

Grade 2 (Commercially Pure): Good balance of strength, ductility, and corrosion resistance.

Grade 5 (Ti-6Al-4V): Most common alloy, high strength, heat treatable.

Superior performance in extreme conditions, including high temperatures, high pressures, and highly corrosive environments.

Examples We Can Machine:

Inconel® (e.g., 625, 718): Excellent oxidation and corrosion resistance at high temperatures.

Monel® (e.g., 400, K500): High strength, resistant to corrosion by acids and seawater.

Hastelloy® (e.g., C276): Outstanding resistance to a wide range of corrosive chemicals.

Extremely lightweight (lightest structural metal), good machinability, but requires special handling due to flammability concerns.

Common Grades We Turn:

AZ31B: Common wrought alloy, good strength-to-weight ratio.

AZ91D: Common die-casting alloy, also available in extruded forms.

Plastics

Offers high stiffness, low friction, excellent dimensional stability, good machinability, and resistance to moisture and chemicals.

Key Properties & Grades:

POM-C (Copolymer): Better chemical resistance, lower centerline porosity.

POM-H (Homopolymer / Delrin®): Higher mechanical strength and stiffness, slightly lower chemical resistance.

Typical Applications:

Gears, bearings, bushings, rollers, electrical insulators, wear strips.

Good toughness, wear resistance, fatigue strength, and chemical resistance, particularly to oils and fuels. Can absorb moisture, affecting dimensional stability.

Common Grades We Turn:

Nylon 6: Good toughness and damping properties.

Nylon 6/6: Higher strength, stiffness, and temperature resistance than Nylon 6.

Cast Nylon (e.g., MC901): Often used for larger parts, bearings, wear pads.

High-performance thermoplastic with exceptional mechanical strength, thermal stability (high operating temperature), chemical resistance, and wear resistance. Often used in demanding applications.

Key Properties & Grades:

Unfilled PEEK: High strength and toughness.

Glass-Filled PEEK: Enhanced stiffness and dimensional stability.

Carbon-Filled PEEK: Increased stiffness, strength, and wear resistance.

Typical Applications:

Aerospace components, medical implants, semiconductor parts, seals, bearings in harsh environments.

Extremely low coefficient of friction, excellent chemical inertness, wide operating temperature range, and good electrical insulation. Mechanically weaker than other engineering plastics.

Key Properties:

Lowest friction plastic.

Resistant to nearly all chemicals.

Non-stick surface.

Typical Applications:

Seals, gaskets, bearings (low load), valve components, non-stick coatings, insulators.

High impact strength (toughness), good temperature resistance, dimensional stability, and optical clarity (transparent).

Key Properties:

Excellent toughness, even at low temperatures.

Good electrical insulation.

Can be optically clear.

Typical Applications:

Machine guards, sight glasses, electronic housings, medical device components, lenses (though less scratch-resistant than acrylic).

Good combination of toughness, impact resistance, stiffness, and ease of machining and processing. Cost-effective.

Key Properties:

Good impact strength.

Easily machined and thermoformed.

Good dimensional stability.

Typical Applications:

Enclosures, housings, prototypes, consumer products, automotive interior parts.

Exceptional abrasion resistance, low coefficient of friction, high impact strength, and good chemical resistance. Does not absorb moisture.

Key Properties:

Highest abrasion resistance of any thermoplastic.

Self-lubricating.

High toughness.

Typical Applications:

Wear strips, chain guides, conveyor components, bearings (low speed), food processing equipment parts.

Good chemical resistance (especially to acids and bases), electrical insulation, and low moisture absorption. Relatively low cost.

Key Properties & Types:

Rigid PVC (Type I): Good strength and chemical resistance.

CPVC: Higher temperature resistance than standard PVC.

Typical Applications:

Chemical processing tanks and fittings, valve components, electrical insulators, piping components.

Excellent optical clarity (transparent), good weather resistance, and rigidity. More brittle and less impact resistant than polycarbonate.

Key Properties:

High transparency and light transmission.

Good UV and weather resistance.

Easily fabricated and polished.

Typical Applications:

Sight glasses, light pipes, displays, decorative elements, lenses (where impact resistance is not critical).

Feature | Description | Benefit |

Precision | Tolerances as tight as ±0.0001 inches | Parts fit together perfectly every time |

Surface Finish | Ra values as low as 0.4 μm | Smooth parts that work better and last longer |

Material Options | Metals, plastics, and composites | Choose what works best for your needs |

Production Speed | Fast cycle times compared to manual methods | Get your parts quicker |

Complex Shapes | Can create intricate profiles and features | Make exactly the part you need |

Cost-Effective | Lower per-part cost at higher volumes | Save money on bigger orders |

Consistency | Every part exactly matches specifications | No surprises when you build |

Let’s dive deeper into these amazing parts!

There are many good reasons to choose CNC turned parts:

High Precision

Our machines can make parts with very tight tolerances—sometimes as small as 0.0001 inches! This means your parts will fit together perfectly.

Excellent Surface Finish

CNC turned parts have smooth surfaces that often don’t need extra finishing. This makes them work better and look nicer.

Cost-Effective for Many Volume Levels

Whether you need 10 parts or 10,000, CNC turning can be a smart choice. At higher volumes, the cost per part goes down a lot.

Fast Production Times

Once we program the machine, making parts is quick. This means you get your order faster than with many other methods.

Consistent Quality

Every part will be exactly the same, so you don’t have to worry about pieces not fitting together.

Let’s see how turning compares to other ways of making parts:

Method | Best For | Limitations |

CNC Turning | Round parts, high precision | Complex non-round shapes difficult |

CNC Milling | Flat surfaces, pockets, complex 3D shapes | Not as efficient for round parts |

3D Printing | Complex prototypes, custom shapes | Slower, often less strong |

Die Casting | High volume simple parts | High initial tooling costs |

Forging | Very strong metal parts | Limited precision, expensive tooling |

For round or cylindrical parts, CNC turning is usually the best choice. It combines speed, accuracy, and value in a way other methods can’t match.

At Istar Machining, quality is our top priority. We check every part using:

Every batch of parts goes through strict checks before we send them to you.

When designing parts for CNC turning, keep these tips in mind:

Our design for cnc machining experts can help improve your designs for better results.

At Istar Machining, we specialize in making exactly what you need. Our custom CNC turning service offers:

We can help improve your designs.

Lorem ipsum dolor sit amet, consect adipiscing elit, sed do eiusmod

We can make parts with hard-to-machine features.

Threading, knurling, milling, drilling, and more.

Anodizing, plating, polishing, and other treatments.

Getting parts from us is easy:

Email us your CAD files or drawings.

We'll review your project and give you pricing quickly.

Once you're happy with the quote, we'll start making your parts.

We make and test your parts to make sure they're perfect.

We ship your parts safely and quickly.

CNC turned parts are amazing for making round, precise components for almost any industry. At Istar Machining, we combine cutting-edge technology with skilled craftsmanship to deliver perfect parts every time.

Whether you need a few prototype parts or thousands of production pieces, our CNC turning services can meet your needs with precision, speed, and value.

Ready to get started? Contact us today for a quote on your CNC turned parts project!

CNC turned parts are made on special machines called CNC lathes. These smart machines use computers to control how they cut material. The material spins very fast while cutting tools shape it into exactly what you need.

Unlike other ways of making parts, turning is all about spinning the material, not the tool. This makes it perfect for making round things like:

A: Almost any material that can be cut can be turned, including all common metals, plastics, and some composites.

A: We regularly hold tolerances of ±0.001″ and can achieve ±0.0001″ in some cases.

A: In turning, the part spins while tools stay mostly still. In milling, the tools spin while the part stays mostly still.

A: Our machines can handle parts from tiny (0.010″ diameter) up to 24″ diameter and 80″ long.

A: Depending on complexity and quantity, lead times can range from a few days for rush jobs to 2-3 weeks for standard orders.

A: Yes! Modern CNC turning is efficient even for small batches. For prototypes or small runs, we have special processes to keep costs down.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or