Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

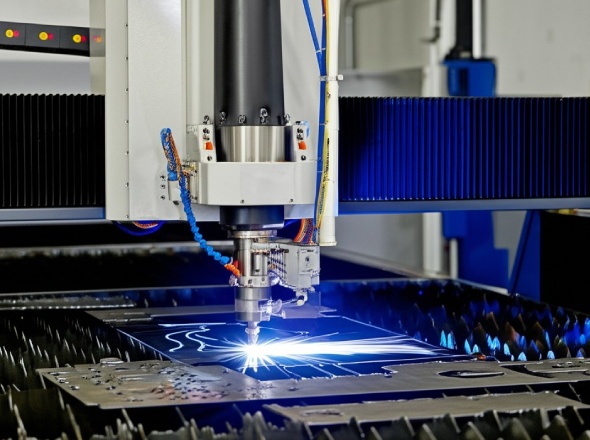

Ready to cut through metal like butter? Let’s explore how CNC plasma cutting works and why Istar Machining offers the best solution for your cutting needs!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

CNC plasma cutting beats other cutting methods for many reasons:

For projects needing both cutting and advanced shaping, our 5 axis machining center gives you even more options!

Istar Machining’s plasma systems can cut almost any metal:

Mild steel and carbon steel are the most commonly processed materials using CNC plasma cutting due to their excellent cutting speeds and cost-effectiveness. We handle a wide range of structural and general-purpose steels.

Common Grades We Cut:

Surface Considerations:

Stainless steel cuts cleanly with plasma, preserving its properties relatively well outside the heat-affected zone (HAZ). We utilize appropriate gas mixtures (like Nitrogen or F5) when necessary for optimal edge quality and reduced oxidation on certain grades.

Common Grades We Cut:

Surface Considerations:

Aluminum’s high conductivity makes it well-suited for plasma cutting, offering fast processing speeds. We handle various common aluminum alloys in sheet and plate form.

Common Grades We Cut:

Surface Considerations:

Beyond the most common materials, our CNC plasma system can also process other conductive metals. Capability and optimal results often depend on the specific alloy and thickness.

Examples Include:

Surface Considerations:

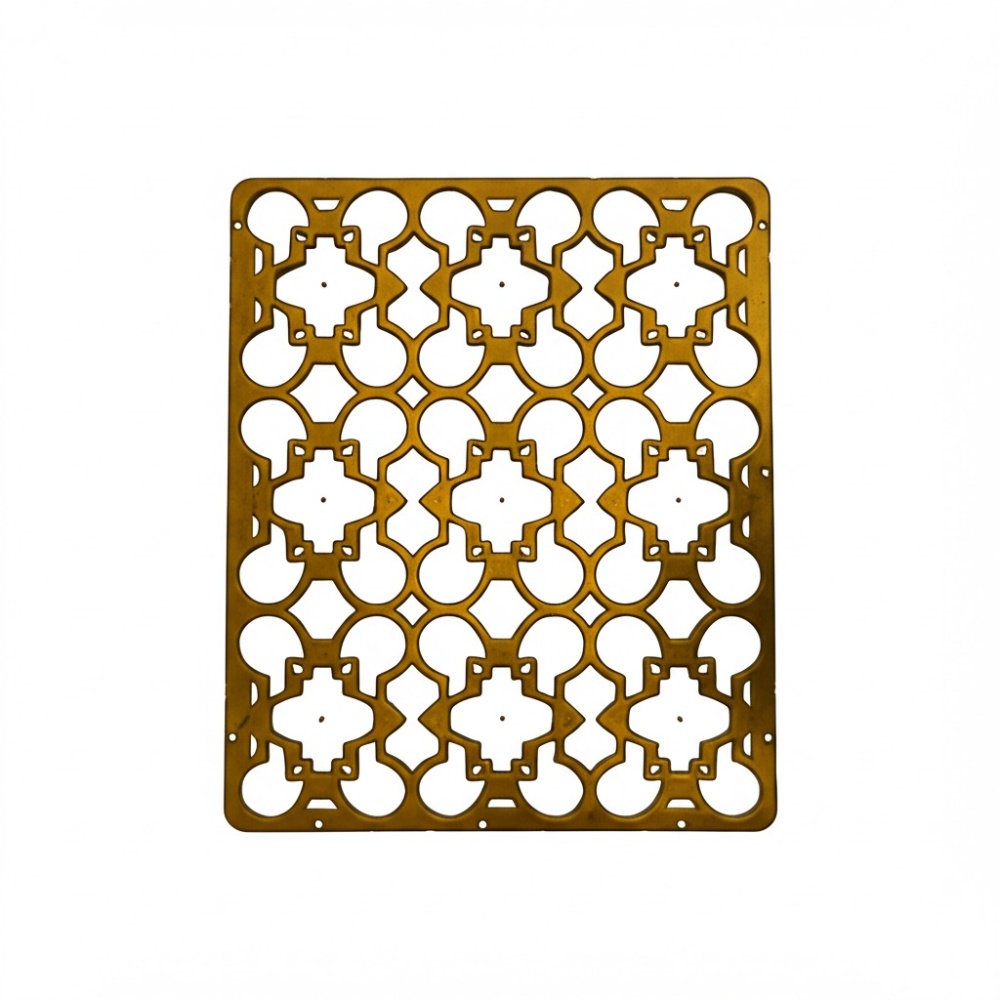

Our plasma cutting helps many kinds of businesses:

Smart businesses choose plasma cutting because:

Energy Efficient: Uses less power than some other cutting methods

For those who like to know the specifics:

When you need metal cut right, we deliver:

Our team knows how to get perfect results

Every part meets exact specifications

Competitive rates with no hidden costs

Fast service when you're in a hurry

We work with you to solve problems

Ready to try our plasma cutting services? Here’s how:

with your project details

usually within 24 hours

the cutting plan

to exact specifications

to your location

Choosing Istar Machining for your CNC plasma cutting means working with experts who understand metal fabrication from start to finish. Our commitment to quality, fair pricing, and customer service sets us apart.

Whether you need one custom part or thousands of production pieces, our plasma cutting services deliver the precision and reliability your project demands. Contact us today to experience the Istar Machining difference!

Ready to start your project? Email [email protected] for a free quote.

CNC plasma cutting uses a super-hot jet of plasma (up to 30,000°F!) to melt through metal.

At Istar Machining, we use the latest plasma cutting technology to make clean cuts on all types of metal projects. Our CNC machining service experts help you get the exact parts you need.

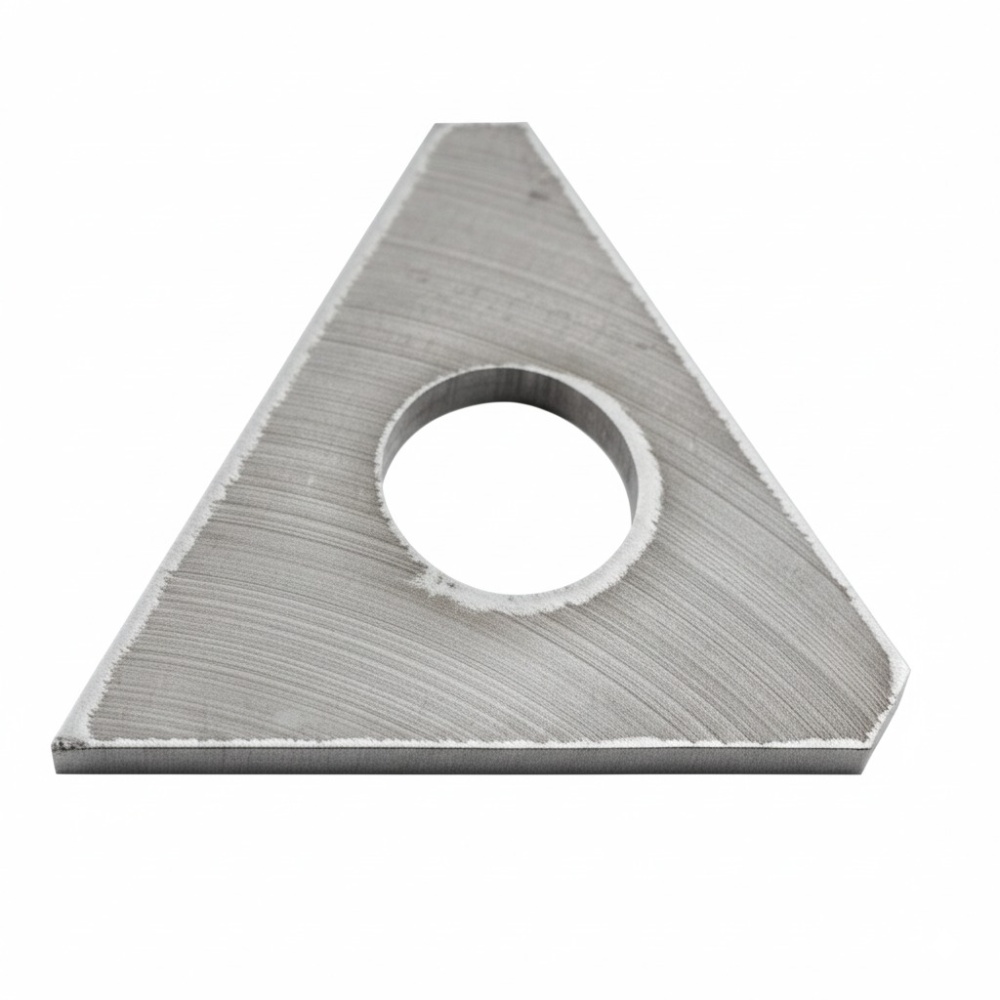

Our systems maintain accuracy within ±0.1mm for most materials.

Yes! Unlike some methods, plasma works fine on rusty, painted, or dirty metal.

We can cut steel up to 50mm thick with our high-power systems.

Plasma typically costs 30-40% less than laser for thick materials.

Yes, we can cut holes as small as the material thickness (e.g., 5mm holes in 5mm steel).

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or