Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for top-quality plastic parts made with amazing precision? At Istar Machining, we turn your ideas into reality with our expert plastic CNC machining services. We make custom plastic parts for medical tools, airplane parts, car parts, and much more!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

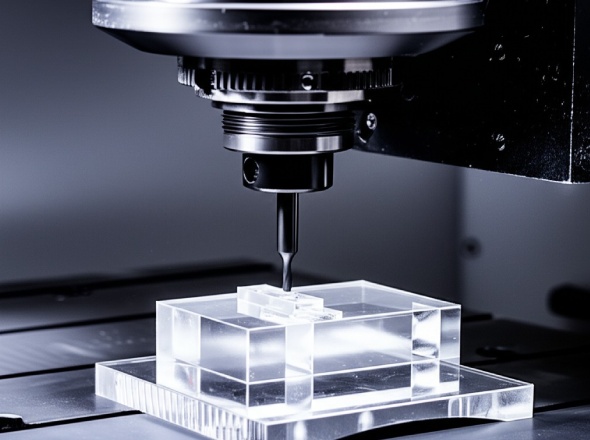

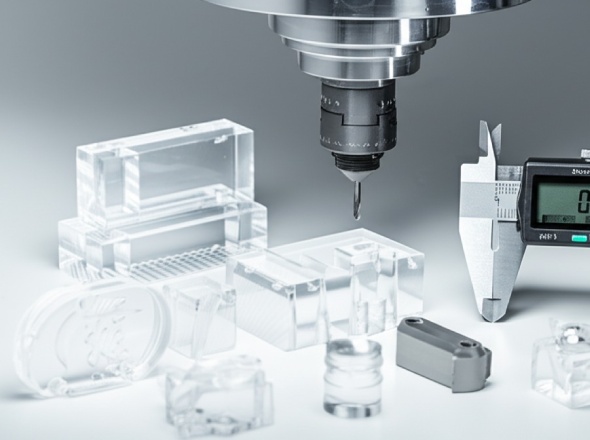

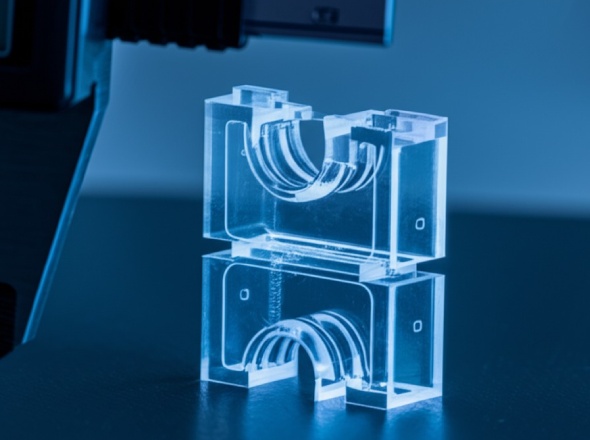

Plastic CNC machining uses computer-controlled tools to cut plastic materials into precise shapes. This makes parts that are very accurate and can be made quickly. Whether you need one test part or thousands of parts, our cnc machining service is perfect for you.

We can machine many types of plastic to fit your needs:

Material | Special Features | Best Uses |

ABS | Strong, easy to machine | Electronic cases, toys |

PEEK | Heat-resistant up to 340°F | Medical tools, airplane parts |

Ultem® | Flame-retardant | Safety equipment |

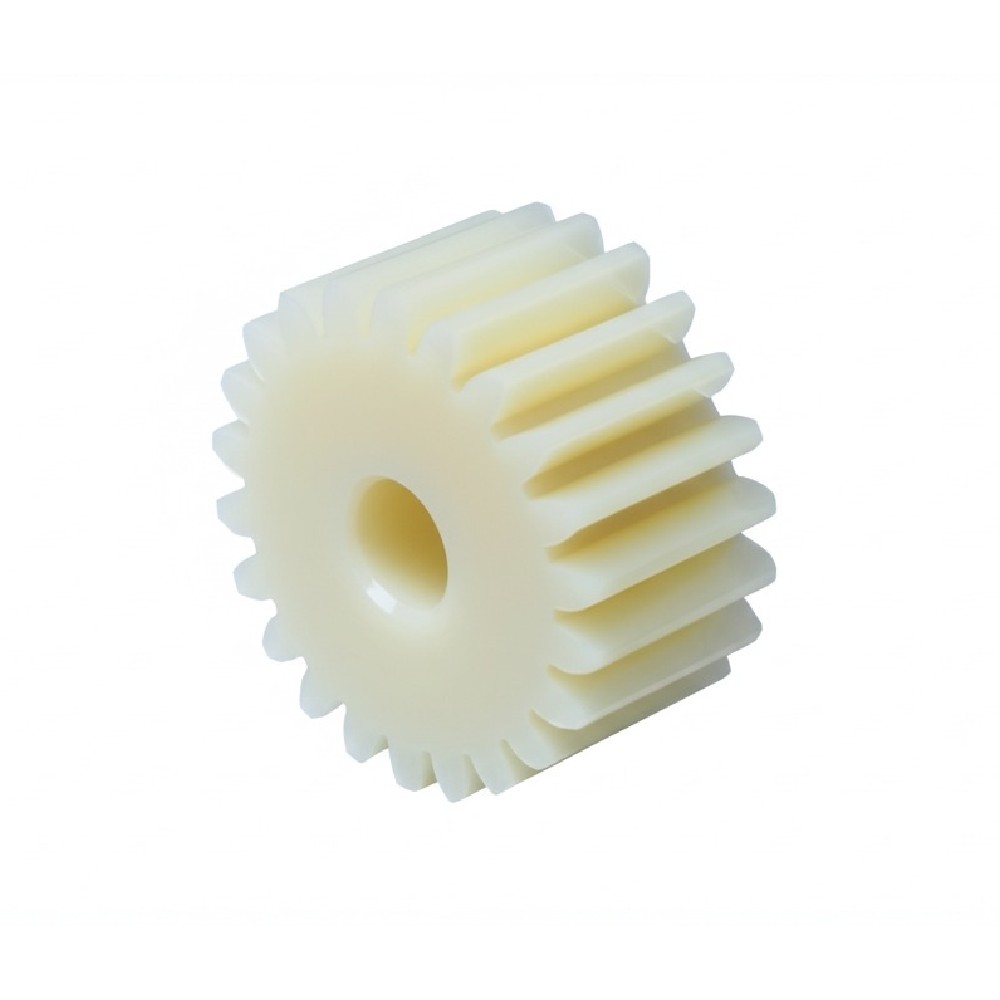

Nylon | Tough and flexible | Gears, bushings |

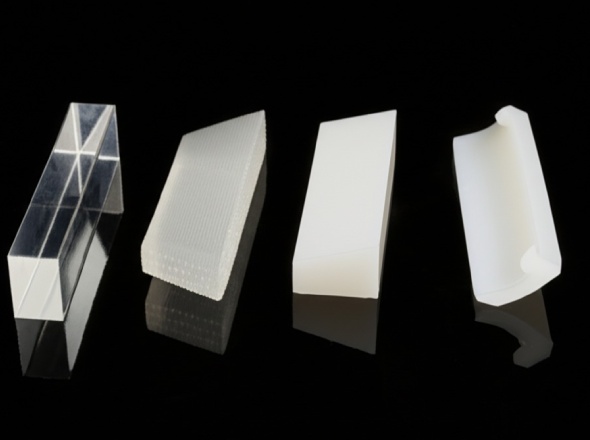

Polycarbonate | Clear and impact-resistant | Windows, shields |

PTFE (Teflon) | Very slippery, chemical-resistant | Food equipment, seals |

HDPE | Food-safe, water-resistant | Containers, cutting boards |

Acrylic (PMMA) | Clear like glass | Light guides, displays |

Delrin® | Low friction, strong | Gears, bearings |

Our team at Istar Machining can help you pick the best plastic for your project. Need medical-grade materials? We have FDA-compliant options too!

Different applications demand different material properties. Here’s a quick guide:

If your part operates in heat, PEEK or PTFE are excellent choices, capable of handling continuous temperatures up to 260°C (500°F).

Need visibility? Polycarbonate (PC) offers exceptional impact strength and clarity, while Acrylic (PMMA) provides excellent optical clarity and aesthetics.

For parts that need to move smoothly against others, Delrin (POM) and UHMW-PE offer excellent lubricity and wear resistance.

When parts come into contact with food, specific grades of UHMW-PE or Delrin (POM) are suitable, meeting regulatory requirements.

For components exposed to the elements, PVC offers good weather and chemical resistance, while Polycarbonate (PC) provides UV resistance and toughness.

Our expertise spans many industries:

Aerospace Industry

Aerospace components demand lightweight yet high-strength materials. PEEK is often used for its excellent mechanical properties and low density.

Medical Devices

Medical tools and equipment require biocompatibility, sterilizability, and precision. PEEK and Delrin (POM) are common choices.

Automotive Sector

Car parts need durability and resistance to heat and fluids. Nylon 6/6 and Delrin (POM) are frequently used for mechanical and fuel system components.

Electronics

Components for electronics often require dimensional accuracy and electrical insulation. PTFE and Acrylic (PMMA) are used for insulators, housings, and light guides.

Industrial Machinery

Factory equipment requires robust parts that withstand continuous operation. UHMW-PE and Nylon 6/6 provide excellent wear resistance for rollers, guides, and bearings.

At Istar Machining, we make parts with amazing precision:

This means your parts will fit perfectly and work just as you designed them. Our 5 axis machining can create complex shapes that other companies can’t make.

Here’s why customers choose Istar Machining for their plastic parts:

We can give your parts many different finishes:

At Istar Machining, we can handle challenging plastic machining jobs:

To ensure the best results and cost-effectiveness for your machined plastic parts, consider these design tips:

We care about the environment at Istar Machining:

We combine advanced technology, skilled machinists, and exceptional service:

in precision plastic machining

for quality assurance

to optimize your parts

without sacrificing quality

for urgent projects

from quote to delivery

Here’s how we turn your idea into a finished part:

CAD file, drawing, or even just an idea

Fast quotes, usually within 24 hours

Our advanced CNC machines create your part

Every part is inspected for perfect dimensions

Polishing, texturing, or other treatments as needed

Ready to bring your plastic part ideas to life? Contact Istar Machining today for a free quote. We’ll help you every step of the way, from material selection to final delivery.

We can handle:

Don’t settle for less than the best for your plastic parts. Choose Istar Machining for precision, quality, and service that exceeds expectations!

CNC machining cuts away material from a solid block, while 3D printing builds up material layer by layer. CNC gives stronger parts with better finish but can waste more material.

Standard time is 3-5 days for prototypes. Need it faster? Our rush service can deliver in as little as 72 hours!

Zero! We can make just one part or thousands. That’s the beauty of cnc plastic machining.

Yes! We can match most Pantone colors with colored plastic or painting services.

Our experts will help you select the best material based on strength, temperature, chemical resistance, and cost needs.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or