Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

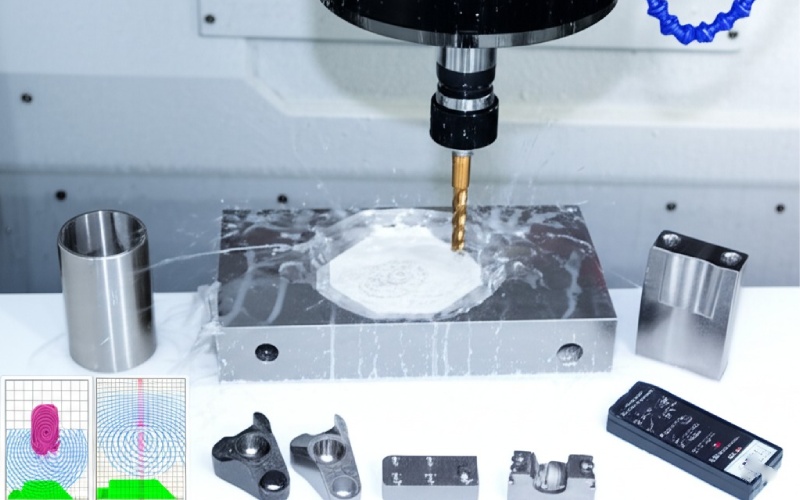

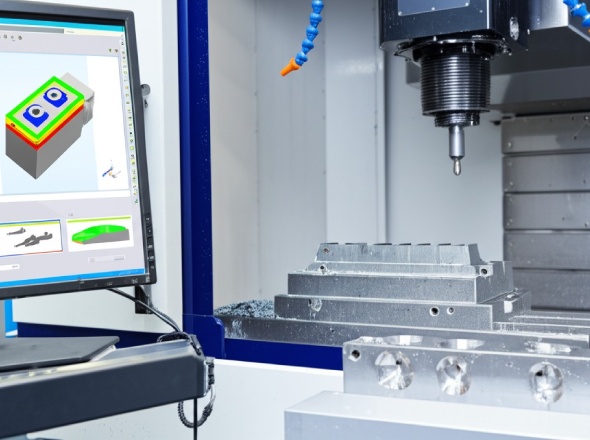

Are you looking for a way to make perfect cavities in your parts? CNC pocket milling is the answer! At Istar Machining, we’re experts at making closed-boundary milling that removes material to exact depths. This guide will show you everything about pocket milling and how our services can help your projects.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

CNC pocket milling makes hollow areas or cavities in a part without cutting all the way through. Think about the space where a screw head sits flush with a surface – that’s a pocket!

Pocket milling uses special tools and movements to create these spaces with exact:

Our process follows these simple steps:

What We Make | How We Use It | Why It’s Great |

Flush fasteners | Aircraft and car parts | Screws sit perfectly flat with the surface |

Mold cavities | Plastic injection molds | Makes spaces for plastic to flow into |

Structural pockets | Lightweight parts | Removes weight while keeping strength |

Pressnut spaces | Assembly points | Creates perfect spots for threaded inserts |

Battery trays | Electronic devices | Makes spaces that hold batteries perfectly |

Optical components | Cameras and devices | Super smooth finishes for sensitive parts |

We use high-feed carbide end mills from top brands like Sandvik to cut material faster and better. Our special methods include:

Different materials offer unique advantages for CNC pocket milling. Here’s a look at what we commonly work with:

Metals

Lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable, making it ideal for pocket milling.

“It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

Offers excellent corrosion resistance, high strength, and durability. Pocket milling requires appropriate speeds and feeds due to work hardening.

“Its durability and resistance to corrosion and heat make it perfect for demanding environments where longevity and hygiene are critical.”

A cost-effective, versatile ferrous metal with good machinability and strength. Prone to rust if not finished or coated.

“Great value for general-purpose applications requiring good strength and ease of fabrication, easily weldable and machinable.”

Steels alloyed with elements like chromium, molybdenum, or nickel to enhance properties like hardness, toughness, and wear resistance. Machinability varies by grade and heat treatment.

“Provides superior strength, hardness, and durability compared to mild steel, suitable for high-performance and demanding applications.”

High strength-to-weight ratio, excellent corrosion resistance, and biocompatible. More challenging to machine due to low thermal conductivity and chemical reactivity.

“Unmatched strength-to-weight ratio and superb corrosion resistance make it ideal for critical applications where performance and low weight are paramount.”

An alloy of copper and zinc, known for excellent machinability, good corrosion resistance, electrical conductivity, and aesthetic appeal.

“Extremely easy to machine, producing excellent surface finishes. Offers good corrosion resistance and a desirable appearance at a reasonable cost.”

Valued primarily for its exceptional electrical and thermal conductivity. Relatively soft and can be ‘gummy’ to machine, requiring sharp tooling.

“Its superior conductivity is essential for thermal and electrical management applications where efficient energy transfer is key.”

The lightest structural metal, offering a good strength-to-weight ratio and excellent machinability. Requires careful handling due to flammability of fine chips/dust.

“Offers significant weight reduction possibilities compared to aluminum, while still being relatively strong and very easy to machine (with precautions).”

Plastics

A common thermoplastic known for its toughness, impact resistance, and ease of machining. Cost-effective choice for many applications.

“A reliable workhorse plastic that’s easy to machine, reasonably strong, impact resistant, and affordable for prototyping and production.”

A strong, tough engineering thermoplastic with excellent wear resistance, low friction properties, and good chemical resistance. Can absorb moisture, affecting dimensional stability.

“Its exceptional wear resistance and toughness make it ideal for moving parts and applications requiring durability and low friction.”

A very durable, transparent thermoplastic with outstanding impact strength, good temperature resistance, and dimensional stability.

“Incredibly tough and shatter-resistant, perfect for applications needing transparency combined with high impact strength.”

An engineering thermoplastic known for its high stiffness, excellent machinability, low friction, wear resistance, and outstanding dimensional stability, especially in wet environments.

“Machines beautifully to tight tolerances and smooth finishes. Its stiffness, low friction, and stability make it a go-to for precision mechanical parts.”

A high-performance engineering thermoplastic offering excellent mechanical strength, stiffness, high temperature resistance, chemical resistance, and wear resistance. Biocompatible grades available.

“Top-tier performance across the board – temperature, chemicals, mechanical stress. Ideal for the most demanding applications where other plastics fail.”

A rigid, transparent thermoplastic with excellent optical clarity and UV resistance. More brittle than Polycarbonate but easier to polish to a high gloss.

“Offers exceptional clarity, similar to glass, but is much easier to machine and fabricate. Great for visual prototypes and optical applications.”

HDPE is cost-effective, chemical resistant, and impact resistant. UHMW offers extremely high abrasion resistance and low friction, but can be harder to machine cleanly.

“(HDPE) Cost-effective solution for chemical resistance and general toughness. (UHMW) Unbeatable wear resistance for sliding applications.”

Other Materials

Materials like glass-reinforced epoxy (G-10/FR-4) or Carbon Fiber offer high strength-to-weight ratios and stiffness. Machining creates abrasive dust and requires specialized tooling and procedures.

“Provides exceptional stiffness and strength relative to weight (especially Carbon Fiber) or excellent electrical insulation and stability (G-10/FR-4).”

Note: Machining composites requires specific expertise and equipment due to abrasiveness and dust generation.

Natural woods and engineered wood products can be pocket milled. Properties vary greatly by type. Suitable for specific applications like jigs, molds, or decorative elements.

“Readily available and relatively easy to machine for creating custom jigs, patterns, or aesthetic components where metal or plastic isn’t required.”

Available in various densities, these materials are very easy and fast to machine. Primarily used for non-functional models and patterns.

“Allows for incredibly fast machining, perfect for quickly creating physical models, verifying designs, and making patterns at low cost.”

We use special probes to ensure your pockets are exactly the right depth

Our techniques create smooth surfaces that need no extra work

We can make pockets with angled walls or curved bottoms

We can finish prototype pockets in just 48 hours!

Need special corner radiuses or floor patterns? No problem!

Pocket milling is perfect for many industries. Here’s where we use it most:

Airplane parts need to be light but strong. We make structural pockets that remove extra material while keeping strength. These parts must meet strict Boeing standards for safety.

Medical parts need precise cavities for components. Our precision medical machining creates perfect fits for things like batteries or sensors.

Your phone or laptop has many tiny pockets inside for parts to fit perfectly. We can make these with tolerances as small as 0.0015"!

Cars need strong, lightweight parts. Our aluminum CNC milling creates perfect pockets for parts that save weight and fuel.

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Ready to make your parts better with perfect pockets? Our team at Istar Machining is ready to help. As a top 5 CNC machining factory in China, we focus on high-precision, custom work that meets your exact needs.

Yes! With our 5-axis machining, we can create pockets with angles, curves, and undercuts that normal machines can’t make.

We can make pockets up to 4 inches (100mm) deep with special tools that reach down while staying accurate.

Just add a note saying “Depth: X.XX” in your design file, or we can help you figure out the right depth.

For aluminum, we use 3-flute carbide end mills with special coatings that cut smooth and fast.

We can make pocket floors with a mirror-like 32 microinch finish – smooth enough for optical components!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or