Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

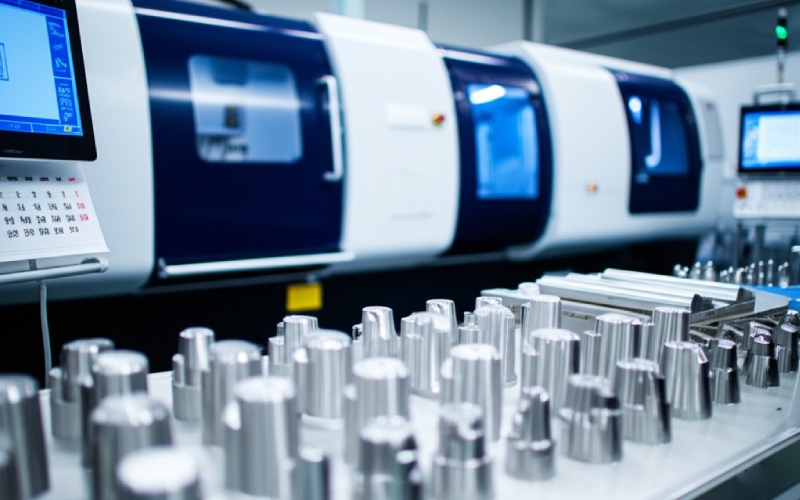

Welcome to Istar Machining’s world of CNC prototype machining! We help turn your ideas into real parts that you can touch, test, and use. Our machines can make parts from many materials with amazing accuracy. Let’s learn how we can help bring your designs to life!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

There are many ways to make test parts. Here’s why CNC machining is often the best choice:

When you need parts fast, we deliver! Our rapid CNC machining service can make your prototypes in just:

This means you can test your ideas and make changes quickly. No more waiting weeks to see if your design works!

Every prototype at Istar Machining comes with free Design for Manufacturability feedback. Our engineers look at your design and tell you:

This advice can save you from expensive mistakes before you make thousands of parts!

Our precision CNC machining can make parts with tight tolerances (±0.001″) that fit perfectly with other components. This level of accuracy means:

Below is a table showing the materials we can use and what they’re best for:

Metals

Common Grades: 6061-T6, 7075-T6, 5052, MIC-6

Key Characteristics:

Common Prototyping Applications: Housings, brackets, heat sinks, automotive parts, aerospace components, consumer electronics casings.

Finishing Options: Anodizing (various colors), bead blasting, powder coating, polishing, brushing.

Common Grades: 303, 304/304L, 316/316L, 17-4 PH

Key Characteristics:

Common Prototyping Applications: Medical devices, surgical instruments, food processing equipment, marine components, durable fixtures, high-wear parts.

Finishing Options: Passivation, electropolishing, bead blasting, brushing, polishing.

Common Grades: 1018 (Mild), 1045 (Carbon), 4140 (Alloy)

Key Characteristics:

Common Prototyping Applications: Jigs, fixtures, structural components, tooling, machine parts requiring high strength where corrosion isn’t the primary concern.

Finishing Options: Black oxide, zinc plating, nickel plating, painting, powder coating.

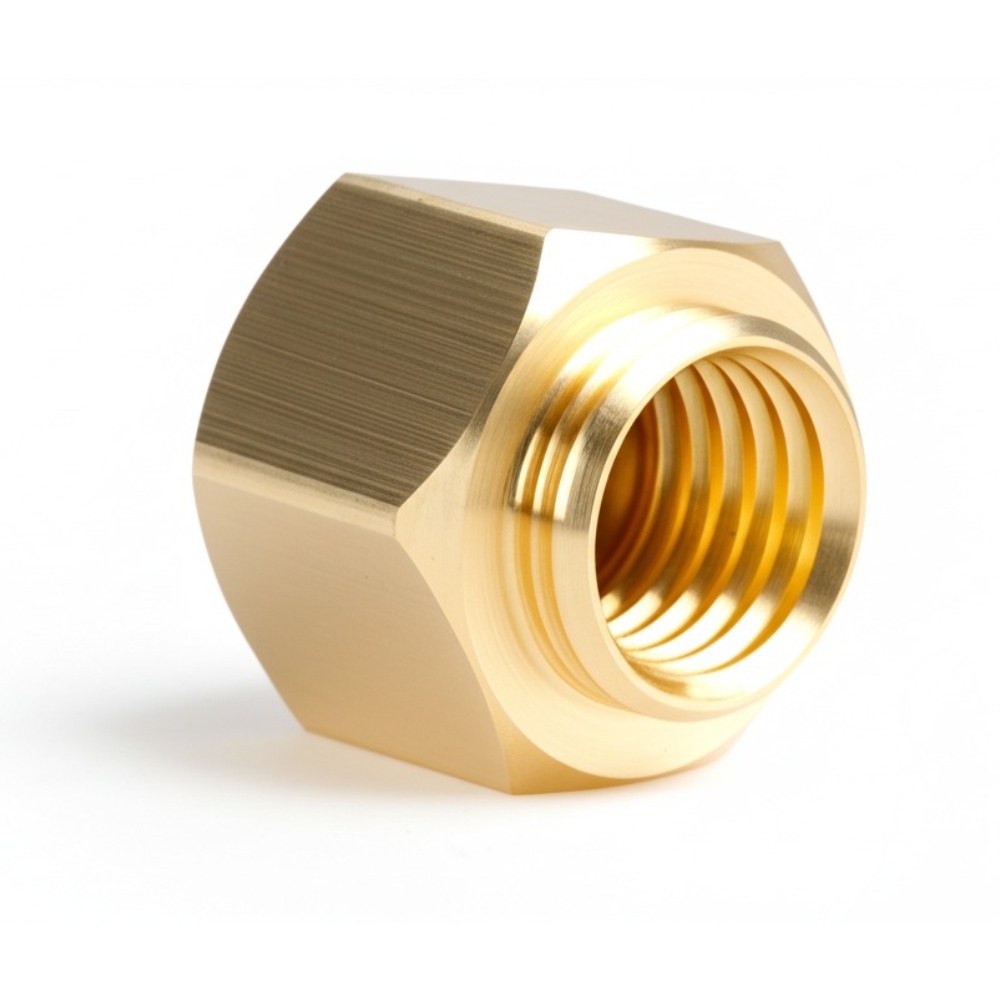

Common Grades: C360 (Free-Machining Brass)

Key Characteristics:

Common Prototyping Applications: Fittings, connectors, gears, musical instrument parts, decorative hardware, electrical contacts.

Finishing Options: Polishing, brushing, plating.

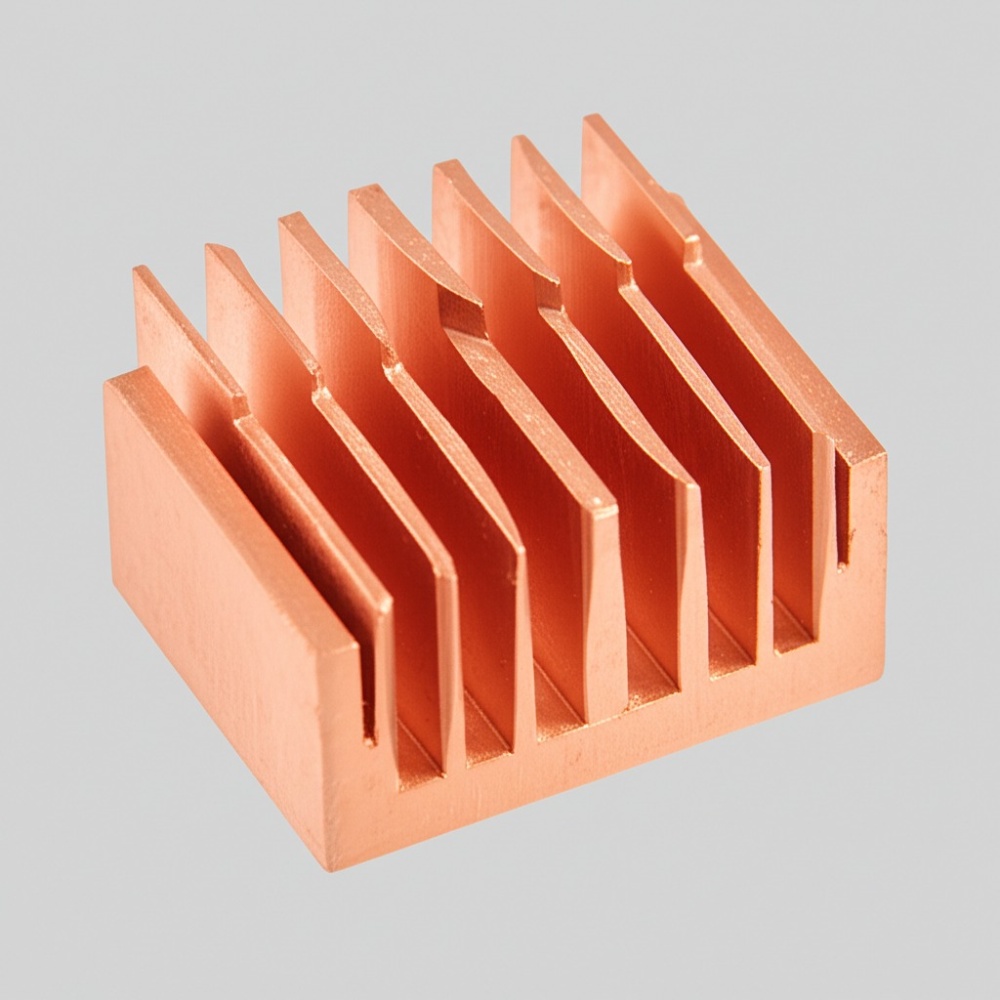

Common Grades: C101 (OFHC), C110 (ETP)

Key Characteristics:

Common Prototyping Applications: Heat exchangers, electrical connectors, busbars, high-conductivity components, artistic elements.

Finishing Options: Polishing, protective coatings.

Common Grades: Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V Alloy)

Key Characteristics:

Common Prototyping Applications: Aerospace components, medical implants, high-performance automotive parts, marine hardware, lightweight structural parts.

Finishing Options: Anodizing (Type II), passivation, bead blasting.

Plastics

Key Characteristics:

Common Prototyping Applications: Enclosures, housings for electronics, consumer product shells, automotive trim components, concept models.

Finishing Options: Smoothing, painting, vapor polishing (limited).

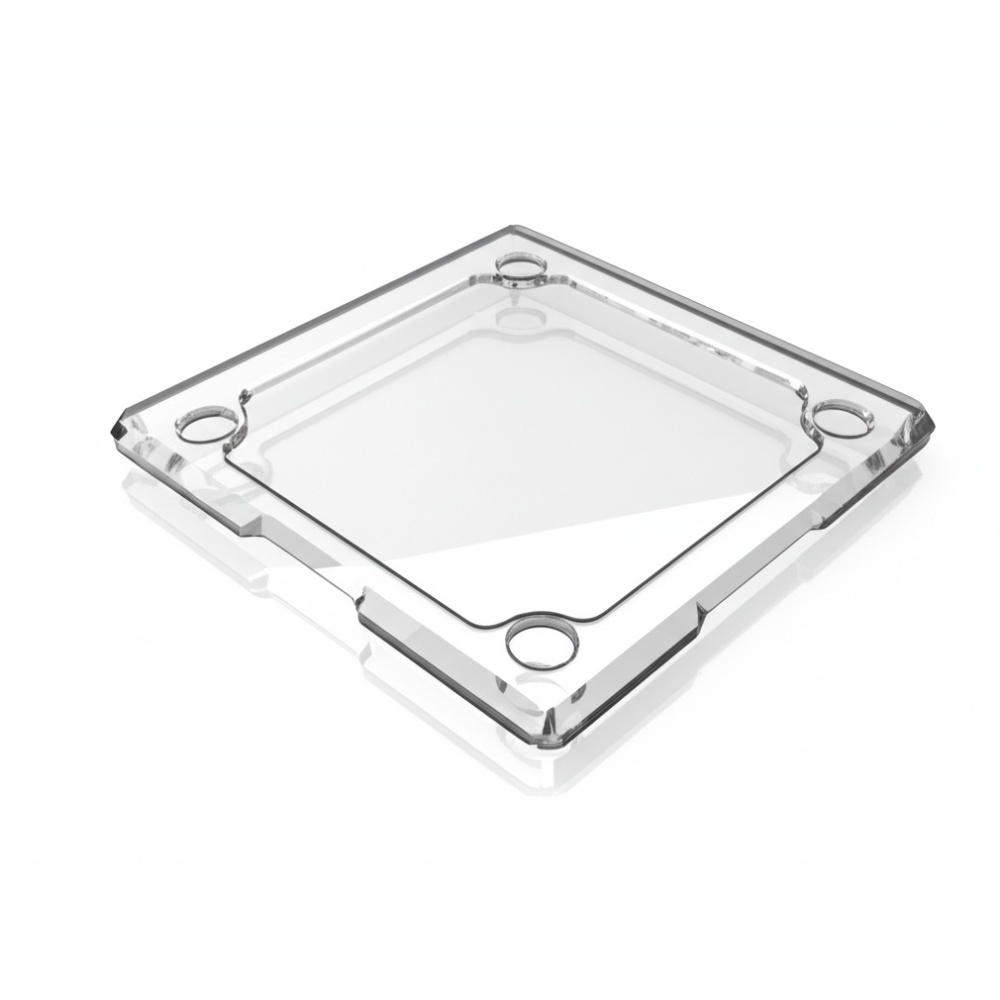

Key Characteristics:

Common Prototyping Applications: Lenses, light pipes, protective guards, durable housings, medical device components, visors.

Finishing Options: Machine polishing, vapor polishing (for clarity).

Common Grades: PA6, PA66 (often glass-filled variants for increased stiffness)

Key Characteristics:

Common Prototyping Applications: Gears, bearings, bushings, rollers, high-wear components, structural parts.

Finishing Options: Dyeing (limited).

Key Characteristics:

Common Prototyping Applications: Precision gears, bearings, bushings, rollers, snap-fit closures, electrical insulators, fluid handling components.

Finishing Options: Usually used as-machined due to excellent finish.

Key Characteristics:

Common Prototyping Applications: Light guides, lenses, display cases, transparent covers, aesthetic models, signage.

Finishing Options: Flame polishing, machine polishing, vapor polishing.

Key Characteristics:

Common Prototyping Applications: Aerospace components, medical implants, semiconductor handling parts, high-temperature seals and bearings, demanding industrial applications.

Finishing Options: Typically used as-machined.

Key Characteristics:

Common Prototyping Applications: Bearings, wear strips, chain guides (UHMWPE), chemical tanks, cutting boards, low-stress mechanical parts.

Finishing Options: Generally used as-machined.

Key Characteristics:

Common Prototyping Applications: Seals, gaskets, low-friction bearings, non-stick surfaces, insulators, chemical handling components.

Finishing Options: Used as-machined.

At Istar Machining, we make prototypes for many different fields:

We make surgical tool prototypes and medical device housings using FDA-compliant materials. Our quality control meets ISO 13485 standards for medical parts.

Our aerospace CNC machining service creates flight-critical parts from aluminum 7075 and titanium. We follow AS9100 standards for aerospace quality.

Car and truck parts need to be strong and precise. We make engine parts, sensor housings, and lightweight brackets for testing new vehicle designs.

Electronics need cases and internal parts that fit perfectly. We make enclosures, heat sinks, and brackets with tight tolerances for perfect assembly.

Robots need precise parts that move smoothly. We create robot arms, grippers, and sensor mounts from aluminum and engineering plastics.

Heavy machinery parts need to be tough. Our steel CNC machining creates valve bodies, pump housings, and hydraulic components that can handle pressure and wear.

Not sure if CNC is right for your prototype? Here’s how it compares:

Feature | CNC Machining | 3D Printing | Injection Molding |

Material Strength | Very High | Medium | High |

Surface Finish | Excellent | Fair | Excellent |

Accuracy | ±0.001″ | ±0.005″ | ±0.002″ |

Material Options | Many metals & plastics | Limited plastics | Many plastics, some metals |

Speed for 1-10 Parts | 2-7 days | 1-3 days | 2-6 weeks |

Cost for 1-10 Parts | Medium | Low | Very High |

Scalable to Production | Yes (1-500 parts) | No | Yes (1000+ parts) |

As you can see, CNC machining gives you the best balance of strength, accuracy, and real materials for functional testing.

When you need prototypes that work like real parts, Istar Machining delivers:

When you send us your design, here’s what happens:

Send us your 3D model (STP, IGES, SolidWorks)

Our engineers check if we can make it (24 hours)

Computer-controlled tools shape your part

Every part is measured to make sure it's perfect

We send your parts using tracked delivery

Most parts take 3-5 days. Simple parts in aluminum can be as fast as 2 days. Complex parts might take 7 days.

CNC machined parts are stronger, more accurate, and use the same materials as production parts. 3D printed parts are often cheaper but not as strong or precise.

Yes! We specialize in making 1-10 prototypes quickly. Unlike injection molding (which needs expensive tools), CNC machining is perfect for making just one part.

We can help you move to low-volume production of 10-500 parts. For larger volumes, we can help you transition to other methods like die casting.

Yes! Our engineers can review your design and suggest changes to make it more manufacturable. This service is included with every prototype order.

CNC prototype machining is a way to make test parts before you make lots of them. We use computer-controlled tools to cut and shape materials into the exact parts you need. These parts work just like the final ones you’ll make later.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or