Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

A CNC quality control plan is your guide to making perfect parts every time. It is a list of rules and actions that direct your whole making process. This plan helps you catch and solve issues before they turn into large problems. Reading this article will show you how to build a simple, good plan. You will learn how to save money, throw away less stuff, and make customers happy by giving them great products.

A CNC control plan is a written set of instructions for your manufacturing team. It tells everyone how to make a product right and the same way every time. This plan includes each step, from the materials you get from a supplier to the final inspection of the finished part. The goal is to make sure every single part is exactly what the customer asked for in the specification. This is a key piece of any good quality management system.

Having a strong quality control plan is very important in today’s industry. It helps you stop problems from happening instead of just fixing them later. When you control the manufacturing process, you lower the chance of making a bad part. This saves you a lot of money because you have less scrap and do-overs (rework). A good plan also makes customers trust you. They know they can count on you to deliver quality products that work as promised. This focus on machining quality control is what makes the best companies stand out.

To implement a plan, you begin with the basics. First, you must know for sure the quality requirements for the part. Look at the drawings and the specification sheet. What is the needed tolerance? What details are most important? This information is the base of your whole quality control process. You need to know what a perfect part looks like before you can make one.

Next, you need to list your process steps. Write down everything that happens to the part from beginning to end. For each step, think about what could go wrong. This is where you can find potential issues. For a new product, this might use a process called FMEA (Failure Mode and Effects Analysis). Your quality manager can be in charge of this. The goal is to create a clear plan that anyone on your team can follow to ensure the product quality is always the same.

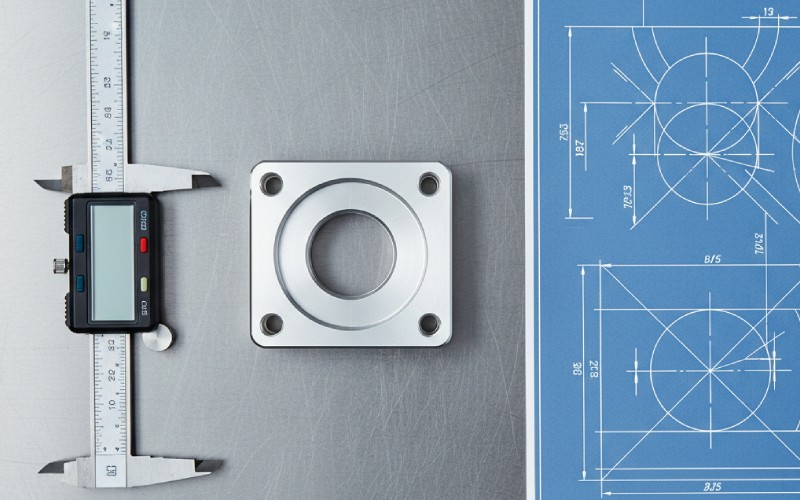

If you cannot measure it, you cannot control it. That is why having the right inspection tool is so important for cnc manufacturing. The tools you need change based on the parts you are making. For simple measurements, you might use calipers or micrometers. For parts with very small allowed differences in tolerance, you might need special tools.

Here is a table of common checking tools used in the CNC industry:

| Inspection Tool | What It Measures | Best For |

|---|---|---|

| Calipers | Length, width, depth | Quick, general checks |

| Micrometers | Very small sizes | High accuracy measurements |

| CMM Machine | Complex 3D shapes | Detailed first article inspection |

| Optical Comparator | 2D outlines and shapes | Checking complex shapes |

Picking the right tool for each inspection helps you get good information. This information tells you if your machining process is going right. Good information is the key to good quality control. A good inspection process helps find any deviation from the standard early, stopping a defective part from being made.

Your measuring tools and CNC machines are only useful if they are correct. Calibration means checking your tools to be sure they measure correctly. Think about using a ruler that is an inch too short. All of your parts would be the wrong size! The same thing can happen with a CNC machine or a micrometer that is not set up right. This is a very important part of cnc quality control.

You should have a regular schedule to calibrate every tool and machine. This is a rule for many industry standards, like ISO 9001. Keep records of every calibration. This certification paper shows that your equipment is correct and that you are serious about quality control. This simple step stops a huge number of problems and is needed for keeping high-quality standards.

Process control means you watch and manage each step of the CNC manufacturing process. It is about more than just checking the last part. It is about making sure the process itself is steady and able to do the job. To do this, you need to watch the main settings on your CNC machines. This includes things like cutting speed, feed rate, and how worn the tool is.

Your plan should write down the right parameter for each job. The person running the machine or the technician should check these settings before every production run. By controlling the process, you can make parts that are almost the same every time. This makes things more alike and makes your final inspection much simpler. Good process control is the secret to making high-quality parts without wasting time or stopping.

Your control method is the “how-to” part of your plan. It gives exact instructions for how to do quality checks at each point. This section should be very clear and simple to understand. It should tell the worker what to check, what tool to use, how often to check, and what to do if they find a problem. A good control method is very clear.

For example, your plan might say: “For the first part of every production run, do a first article inspection. Measure sizes A, B, and C with a digital caliper. All measurements must be inside the allowed tolerance. Write the results on the inspection report. If a measurement is wrong, stop the machine and tell the boss.” This level of detail helps ensure everyone follows the same strict rule.

Statistical process control (SPC) is a very useful tool for quality management. Instead of checking every single part, you use numbers and math to watch the manufacturing process. You check a few parts during production and measure them. Then, you put these numbers on a special graph. This graph shows you if your process is steady or if it is starting to change.

Using SPC helps you find problems early. If you see numbers getting close to a specification limit, you can make a corrective fix. This way of acting first helps minimize the risk of defects. It makes your process capability better, which is your ability to make good parts all the time. While it sounds hard, basic SPC is easy to implement and can greatly enhance how well your work runs.

Your product quality is also about the quality of the materials you start with. That is why managing your supplier is a big part of your quality control plan. Before you work with a new supplier, you should look at how they control quality. Do they have their own quality assurance program? Do they have certification like ISO 9001?

Once you pick a supplier, your control plan should have steps for checking materials that arrive. You do not have to check every single piece of material. You can use a sampling plan to check a small part of each delivery. Following the criterion for checking new materials makes sure you are not building good parts from bad material. This stops a big slowdown later on and keeps all your cnc operations safe.

A plan is only good if you use it and keep it new. Paperwork is the proof that you are following your quality control plan. This includes completed inspection reports, calibration records, and training notes. These papers are very important. They help you see how you are doing, solve problems, and show customers that you meet their quality standards.

An audit is an official check to see if you are following your plan. You can do internal audits, where your own team checks the process. You can also have external audits from customers or certification groups. An audit helps you find places where you can get better. It is not about finding who to blame. It is about finding ways to make your quality control system better and work well, pushing you to continuous improvement.

A well-made cnc machining quality control plan does more than just stop bad parts. It helps make your whole operational work process smoother. When everyone knows their job and the rules they need to follow, work gets done faster and with less errors. This lowers the need for rework and other problems that can lead to increased costs.

In the end, a focus on effective quality helps you make your business bigger. Happy customers return and tell others about you. Being known for good quality can be a great way to get more business. In businesses with many rivals, like the automotive or aerospace manufacturing industry, a proven quality control system can help you get big jobs. It lets you optimize your production and do better than customers expect.