Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

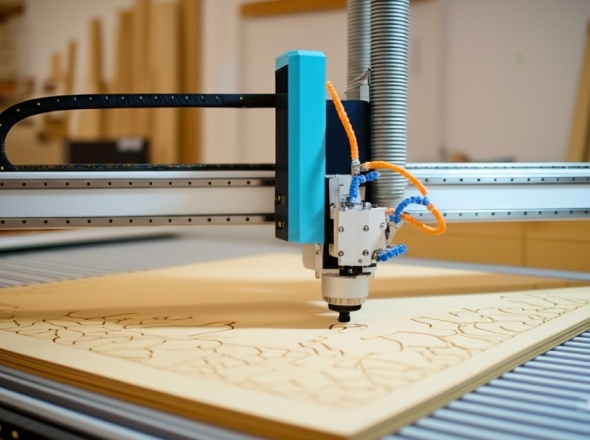

Are you looking for a way to make exact cuts in many types of materials? A CNC routing service might be just what you need! This guide will help you understand what CNC routing is, what it can do, and why it might be perfect for your next project.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

CNC routing is a way to cut materials using a computer-controlled machine. The letters “CNC” stand for Computer Numerical Control. This means a computer tells the cutting tool exactly where to go, making very precise cuts every time.

CNC routing is like having a super-smart robot that can cut almost any shape you can draw on a computer. It’s used to make all kinds of things, from signs to furniture to airplane parts!

These amazing machines can do many different tasks:

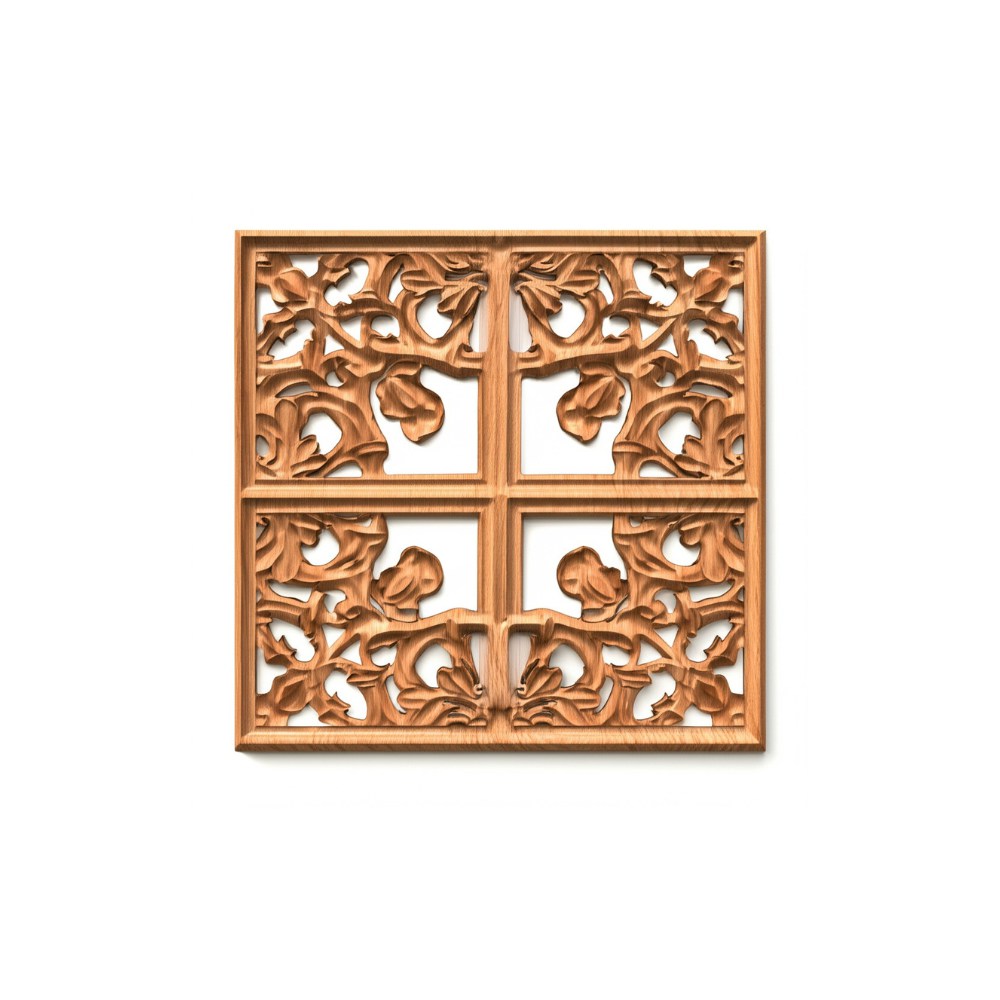

For instance, if you’re making 3D wood CNC projects, the machine can carve beautiful 3D designs that would be very hard to make by hand.

CNC routing is very exact. Let’s look at the numbers:

Precision Level | Measurement | What It’s Good For |

Standard | ±0.005″ | Most regular projects |

High-Precision | Even tighter tolerances | Aerospace and medical parts |

This means when you ask for a part that’s 5 inches long, it will be 5 inches long – not 5.05 or 4.95 inches. This is very important when parts need to fit together perfectly!

Our versatile CNC routing capabilities allow us to precisely cut a wide variety of materials to meet your specific project needs. Whether for prototypes, production runs, signage, or custom parts, we have the expertise to deliver high-quality results. Here’s a look at the materials we commonly work with:

Woods & Soft Metals

(Common Types: Oak, Maple, Walnut, Pine, Poplar)

(Common Grades: Baltic Birch, Marine Grade, Hardwood Plywood)

(Common Grades: 6061, 5052, 3003)

Plastics

(Common Brands: Plexiglas, Lucite; PMMA)

(Common Brands: Lexan, Makrolon; PC)

(Common Brands: Sintra, Komatex, Celtec)

(Common Brands: Delrin, Celcon; POM)

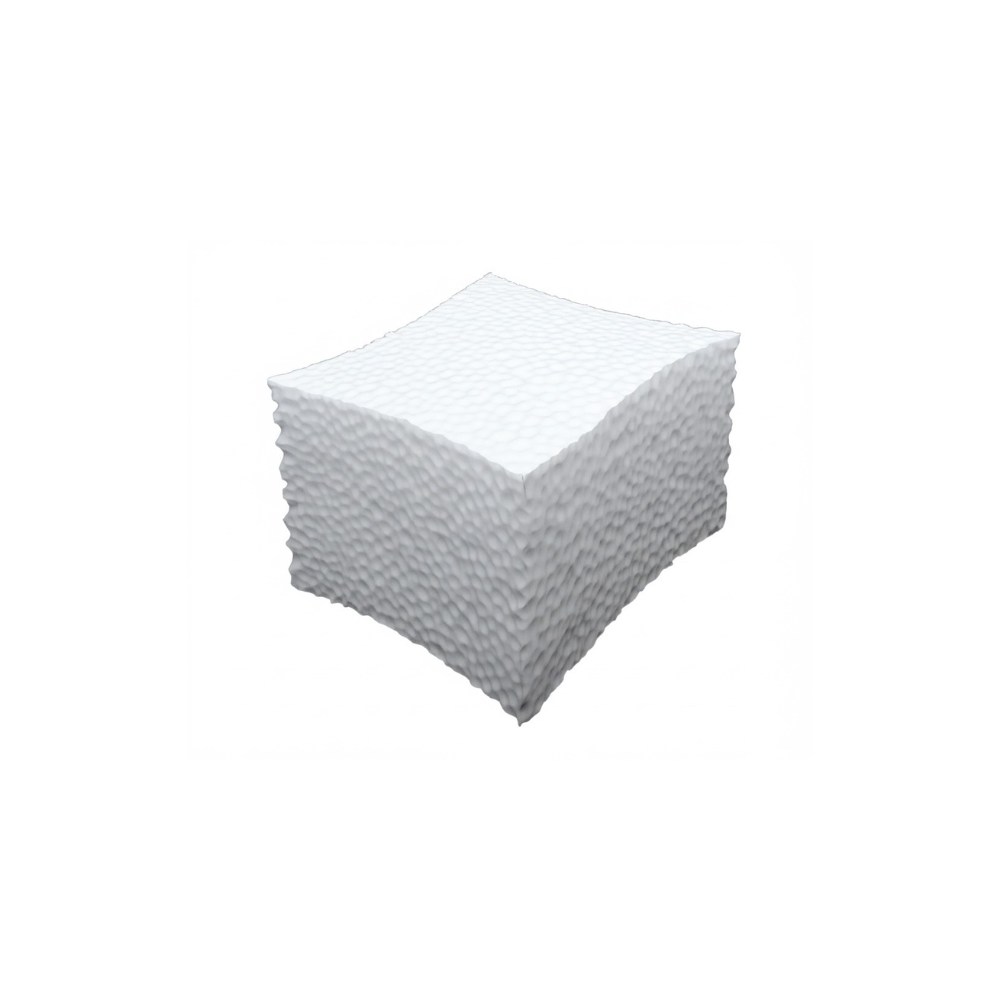

Foams & Composites

(Common Brands: SignFoam, Precision Board)

(Common Brands: Foamular)

(Common Brands: Dibond, Alupanel, ePanel)

(Grades: G10, FR4, LE)

CNC routing helps many different types of businesses:

Aerospace companies need lightweight aluminum components that are super precise. These parts must be exactly right because they go into planes and spaceships where safety is critical.

Car makers use CNC routing for prototypes and molds. They need to test new designs quickly, and CNC routing lets them make parts fast.

Stores and businesses need eye-catching signs that look professional. CNC routing can cut logos and letters perfectly every time.

Furniture makers use CNC routing for cabinet doors and decorative parts. This helps them make beautiful furniture that fits together perfectly.

Architects use CNC routing to make models of buildings and special panels for walls and ceilings.

Here’s how the CNC routing process works from start to finish:

First, you create your design on a computer using CAD software

The design gets turned into instructions the machine can understand

You choose the right material for your project

The CNC operator sets up the machine with the right tools

The machine follows the instructions to cut your design

After cutting, the parts might need sanding or other finishing

There are many good reasons to use CNC routing services:

There are several kinds of CNC routing available:

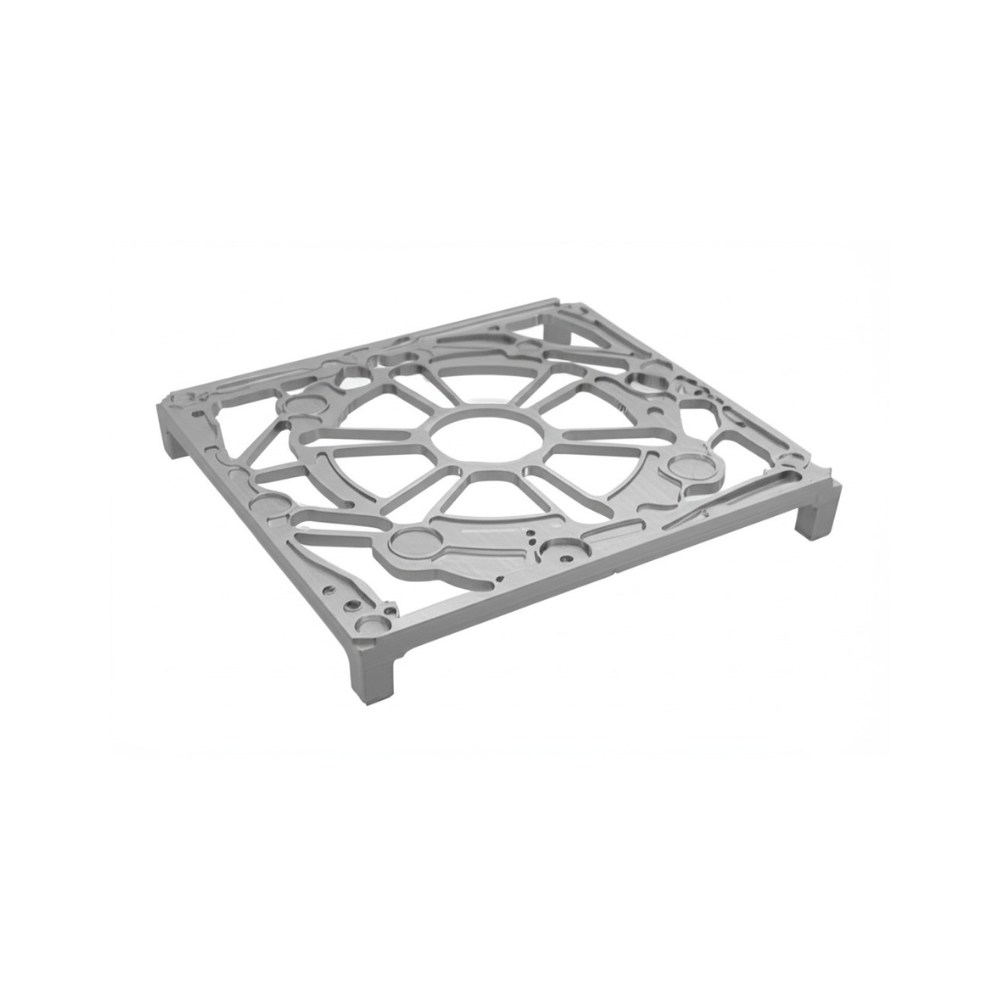

This process enables machining on both the top and bottom faces of a material. Precise alignment during workpiece flipping is crucial.

Ideal For: Parts requiring through-cuts, pockets, or detailed features on opposite sides. Common Uses: Double-sided signage, furniture components, jigs & fixtures.

Learn more about 2-sided CNC routing.

Utilizes simultaneous X, Y, and Z axis motion to carve 3D shapes, contours, and reliefs, typically on one primary face of the material.

Ideal For: Creating complex topographical surfaces, slopes, and curved profiles.

Common Uses: Mold & pattern making, 3D signage, prototypes, artistic carving.

Learn more about 3D CNC routing.

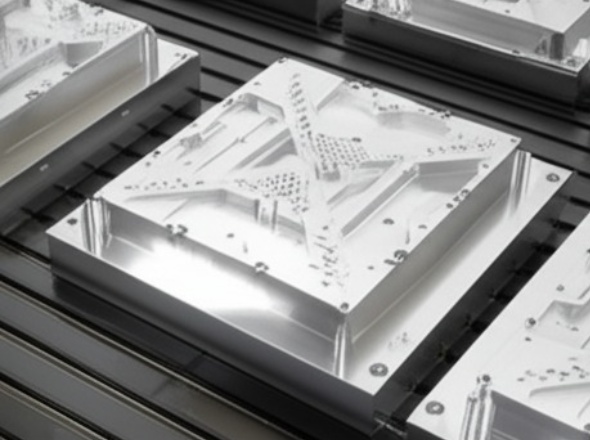

Adds two rotational axes (A and B/C) to the standard X, Y, Z linear axes. This allows the cutting tool to approach the workpiece from virtually any angle.

Ideal For: Highly complex geometries, undercuts, and machining multiple sides of a part in a single setup for maximum accuracy.

Common Uses: Aerospace & automotive components, complex molds, medical devices, intricate prototypes.

Learn more about 5-axis routing.

When picking a service, look for these things:

CNC routing is an amazing technology that can help bring your ideas to life. Whether you need parts for a business, a hobby project, or something completely new, CNC routing offers precision, versatility, and value.

Ready to start your CNC routing project? Contact a professional service today to discuss your needs and get your ideas moving from the computer screen to reality!

Make sure your file is in the right format

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Most services accept common file types like DXF, DWG, and STL files. These are standard in design software.

Standard machines can handle sheets up to 48″ x 96″, which is the size of a standard sheet of plywood. Larger machines exist for bigger projects.

Simple projects might be done in 24-72 hours. More complex jobs take longer. Many shops offer rush services if you need parts quickly.

The cost depends on your project’s complexity, material, and size. For many projects, CNC routing is very cost-effective because it’s fast and wastes less material.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or