Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

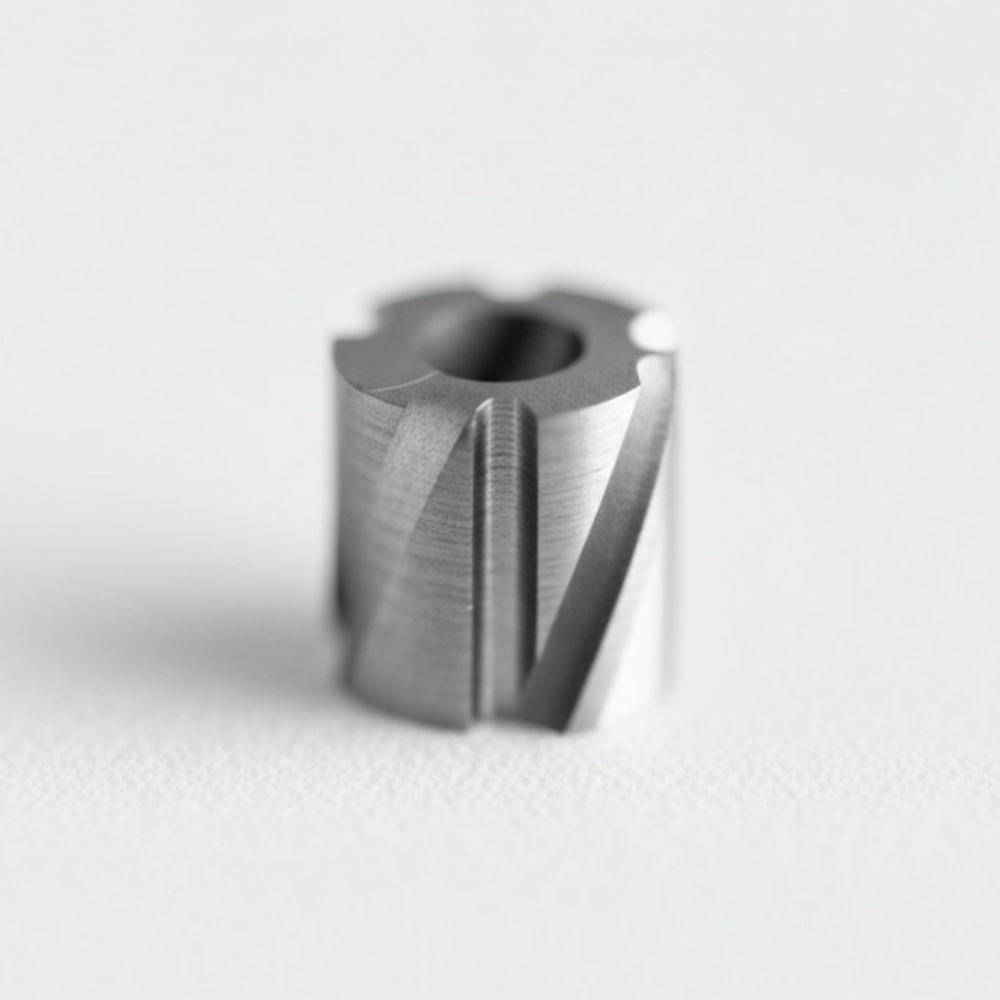

Welcome to Istar Machining’s world of precision! Our CNC Swiss Turning services offer amazing accuracy for making small, complex parts. This guide will show you everything you need to know about this special machining process.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Swiss turning is special because:

When you need parts that must be perfect, CNC swiss turning is the top choice for engineers who need reliable results.

Our machines can work with many different materials:

Metals

Lightweight, excellent strength-to-weight ratio, good conductivity, and highly machinable. Aluminum is a versatile and cost-effective choice for numerous applications.

Common Grades:

6061-T6: Versatile, good strength & corrosion resistance (Most common).

7075-T6: High strength for demanding applications.

2024-T3: High strength, good fatigue resistance (Aerospace).

2011-T3: Excellent machinability for complex parts.

Typical Applications: Electronic Housings, Connectors, Medical Device Parts, Aerospace Fittings, Heat Sinks, Optical Components.

Finishing Options: As Machined, Anodizing (Type II & III), Chromate Conversion, Bead Blasting, Polishing, Tumbling, Painting/Powder Coating.

Known for superior corrosion resistance, strength, durability, and hygiene. Various grades offer specific properties for diverse environments.

Common Grades:

303: Free-machining, good corrosion resistance.

304/L: Most common austenitic, excellent corrosion resistance.

316/L: Enhanced corrosion resistance (Marine, Medical).

416: Free-machining martensitic, heat-treatable for hardness.

440C: High hardness & wear resistance after heat treatment.

17-4 PH: High strength via precipitation hardening.

Typical Applications: Medical Instruments & Implants, Aerospace Fasteners, Food Processing Parts, Valve Components, Shafts, Watch Parts.

Finishing Options: As Machined, Passivation (Critical), Electropolishing, Heat Treating (for hardenable grades), Bead Blasting, Tumbling/Polishing.

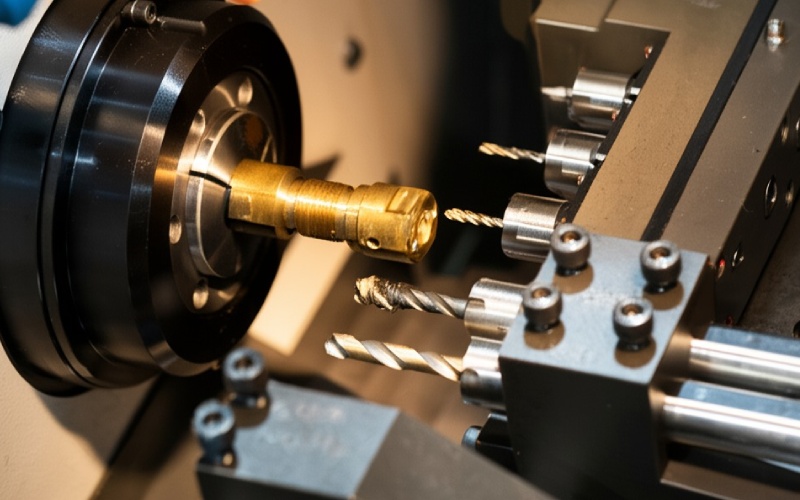

An alloy of copper and zinc, valued for exceptional machinability, good corrosion resistance, conductivity, and appearance.

Common Grades:

C360 (Free-Cutting): Industry standard for high-speed machining.

C260 (Cartridge): Better cold working, less machinable than C360.

Typical Applications: Plumbing Fittings, Electrical Connectors, Fasteners, Small Gears, Decorative Hardware, Instrument Parts.

Finishing Options: As Machined, Polishing, Tumbling, Plating (Nickel, Chrome, Gold, Silver, Tin).

Exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility. Maintains properties at elevated temperatures.

Common Grades:

Grade 2 (CP): Good balance of strength and ductility.

Grade 5 (Ti 6Al-4V): High strength, heat treatable (Aerospace, Medical workhorse).

Grade 23 (Ti 6Al-4V ELI): Higher purity Grade 5 for medical implants.

Typical Applications: Medical Implants (Screws, devices), Aerospace Fasteners & Components, Performance Automotive Parts, Marine Hardware.

Finishing Options: As Machined, Anodizing (Color or wear resistance), Passivation, Bead Blasting, Polishing, Precision Cleaning.

Cost-effective materials offering a range of strengths, hardness (often enhanced by heat treatment), and wear resistance. Includes low-carbon, high-carbon, and alloyed grades.

Common Grades:

12L14 / 1215: Free-machining, excellent for high volume production.

1018: Low carbon, general purpose, good weldability.

4140: Alloy steel, good toughness, hardenable via heat treatment.

8620: Alloy steel, often used for carburized parts (gears).

Typical Applications: Shafts, Fasteners, Pins, Gears, Automotive Components, Machinery Parts.

Finishing Options: As Machined, Heat Treating (Hardening, Tempering, Case Hardening), Plating (Zinc, Nickel, Chrome), Black Oxide, Passivation (less common), Tumbling/Deburring.

We also machine specialized alloys for extreme conditions or unique properties.

Examples: Nickel Alloys (Inconel®, Monel®), Cobalt-Chrome (CoCr), Tungsten Alloys, Magnesium Alloys.

Typical Applications: High-Temp Engine Components, Chemical Processing Parts, Medical Implants (CoCr), Specialized Fixtures.

Finishing Options: Highly material-dependent. Includes specialized coatings, heat treatments, electropolishing, precision cleaning. Contact us to discuss.

Plastics

High-performance thermoplastic; excellent strength, chemical/temp resistance, biocompatible grades available.

Common Grades: Unfilled, Glass-Filled, Carbon-Filled, Bearing Grade, Medical Grade.

Typical Applications: Medical Implants & Instruments, Aerospace Connectors, Semiconductor Parts, Seals, Bearings.

Finishing Options: As Machined, Vapor Polishing (potential), Annealing (stress relief).

High stiffness, low friction, excellent dimensional stability, easy to machine.

Common Grades: Homopolymer (Delrin®), Copolymer, Filled Grades (PTFE/Glass).

Typical Applications: Small Gears, Bushings, Rollers, Electrical Insulators, Snap-Fit Parts, Fluid Components.

Finishing Options: As Machined (often naturally smooth), Tumbling/Deburring.

Tough, durable, good wear and chemical resistance. Moisture absorption can affect dimensions.

Common Types: Nylon 6, Nylon 6/6, Glass-Filled Nylon.

Typical Applications: Rollers, Wear Pads, Guides, Housings, Structural Components (where moisture isn’t critical).

Finishing Options: As Machined, Tumbling/Deburring.

Extremely low friction, excellent chemical inertness, high-temp resistance, excellent insulator. Can be challenging to hold tight tolerances.

Common Grades: Virgin PTFE, Filled PTFE (Glass, Carbon, Bronze – for improved mechanical properties).

Typical Applications: Seals (O-rings, gaskets), Electrical Insulators, Valve Seats, Low-Friction Liners/Bushings.

Finishing Options: As Machined (Surface finish can vary).

Our capabilities extend to other advanced plastics based on project needs.

Examples: Ultem® (PEI – high temp strength), Polycarbonate (PC – impact strength, clarity needs care), Vespel® (PI – extreme temps), PVC, Polypropylene (PP).

Typical Applications: Medical Components (Ultem®), Guards/Lenses (PC), Aerospace Seals (Vespel®), Fluid Handling (PVC/PP).

Finishing Options: Material-dependent. Includes As Machined, Polishing (some types), Annealing. Contact us to discuss specifics.

Why do engineers choose CNC turning with Swiss-type machines? Here are the big benefits:

Precision Like No Other

Speed and Efficiency

Complex Part Capability

At Istar Machining, we can make parts that would be impossible with regular machines:

Quality Assurance

Every part we make goes through tough testing:

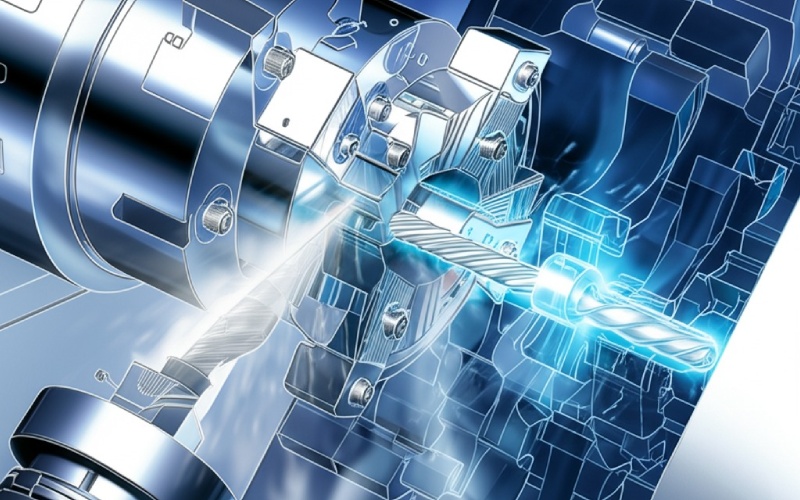

Istar Machining uses the best equipment for perfect results:

Our Esprit CAM integration makes sure there are no collisions during machining, keeping your parts safe.

Whether you need one part or thousands, we’ve got you covered:

We follow all the important rules:

We provide full documentation and material traceability for every job.

23 Years of success making complex parts

The best Swiss turning machines available

Certified processes that ensure perfect parts

Helpful experts who understand your needs

Competitive prices without sacrificing quality

Ready to make your perfect parts? Here’s how to work with us:

.STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Usually within 24 hours

with careful attention to detail

ensures everything is perfect

On time, every time

Ready to get started on your precision parts? Contact our team to discuss your Swiss turning needs!

Let us show you why engineers trust Istar Machining for their most challenging CNC turned parts projects!

CNC Swiss Turning is a special way to make parts with super high precision. It started in Switzerland for making watch parts. Now, we use it at Istar Machining to make all kinds of small, complex parts that need to be perfect.

Unlike regular machining, Swiss machining uses a cool “sliding headstock” that holds the material close to where cutting happens. This makes parts that are more exact and have better finishes.

A: Most prototype orders ship in 5-10 days, with rush options available.

A: We regularly hold tolerances of ±0.0002″ with post-process grinding for even tighter specs.

A: Yes! We work with many engineering plastics like PEEK, Delrin, and polycarbonate.

A: We can machine features as small as 0.1mm (0.004″).

A: We use CMM verification and provide full inspection reports with every order.

If you care more about appearance, corrosion margin and extrusion-friendly shapes, 6063-T52 usually wins. If you care more about structural

If you work in construction, fabrication, CNC machining, product design, or procurement, you’ve probably hit this exact moment: “The drawing

You almost never choose between a bearing and a bushing because of friction alone. You choose because of how you