Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

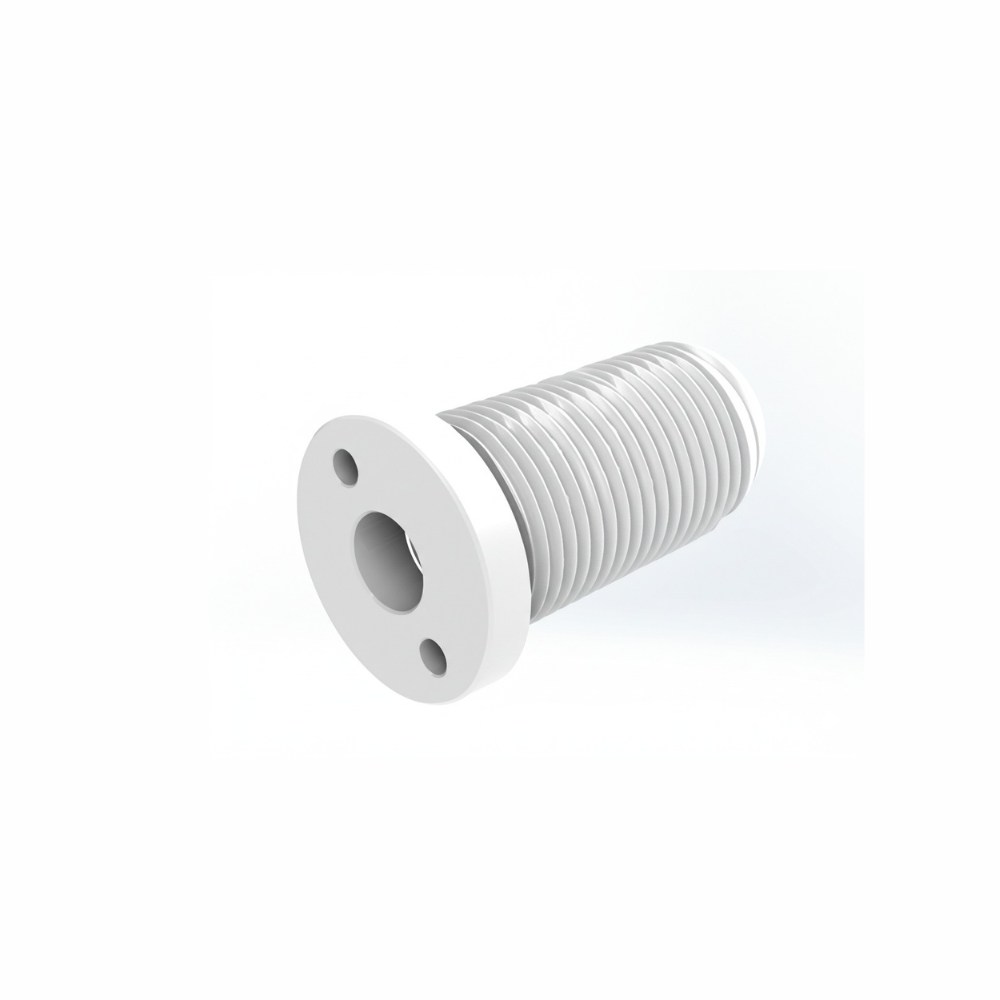

Are you looking for a better way to make threads? CNC thread milling might be just what you need! This modern way of making threads uses special rotating tools to cut perfect internal and external threads. It works way better than old-style tapping for many jobs.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

CNC thread milling uses a special spinning tool that moves in a spiral path to create threads. Unlike tapping, the tool doesn’t need to be the same size as the thread. One tool can make many different thread sizes!

Our CNC milling service experts use thread milling for both inside and outside threads with super high accuracy.

Thread milling has big advantages over old-style tapping:

As experts in CNC prototype machining, we know when thread milling is the best choice for your project.

Thread milling is perfect for many industries. Here’s where we use it most:

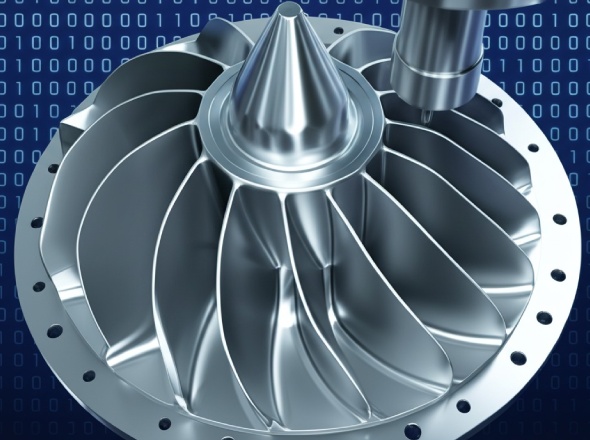

We mill high-strength threads in turbine blades using Inconel 625. These parts must be perfect with no room for error. The threads need to hold together even in extreme heat.

Engine blocks and suspension parts need strong, precise threads. We use thread milling for these parts because it creates stronger threads than tapping.

Medical implants and surgical tools need perfect threads that won't fail. We can mill threads in both stainless steel and plastic medical parts with accuracy to ±0.001".

Pipeline fittings with NPT threads must not leak under pressure. We mill these threads with perfect form to make sure they seal tight every time.

We use only the best tools for CNC thread milling:

Tool Type | Coating | Best For | Features |

Solid Carbide | Nano AlTiN | Aerospace parts, Inconel 625 | Heat resistant, long life |

Helical Flute | TiCN | Stainless steel, automotive parts | Excellent chip evacuation |

Multi-form Thread Mills | ZrN | Medical parts, small threads | Can cut M1.6 threads without breaking |

Indexable Insert | None | Large pipe threads, oil & gas | Cost-effective for big threads |

Different materials are better for different jobs. Here’s what works best:

Metals

Aluminum Alloys (e.g., 6061, 7075, 2024) are highly machinable and offer excellent strength-to-weight ratios.

Good for:

Why customers love it: “Aluminum threads beautifully, allowing for fast cycle times and cost-effective production. Its natural corrosion resistance and light weight are perfect for our applications.”

Stainless Steel Alloys (e.g., 303, 304, 316, 17-4 PH) provide excellent corrosion resistance, strength, and durability.

Good for:

Why customers love it: “The corrosion resistance of stainless steel threads is unmatched for our harsh environments. They hold up incredibly well and maintain their integrity long-term.”

Carbon & Alloy Steels (e.g., 1018, 1045, 4140, 4340) offer high strength, hardness, and wear resistance at a lower cost than stainless steel. Can be heat-treated for enhanced properties.

Good for:

Why customers love it: “Steel provides the raw strength we need for our threaded assemblies. The ability to heat-treat gives us the exact hardness and durability required for demanding applications.”

Titanium Alloys (e.g., Grade 2, Grade 5 / Ti-6Al-4V) boast an exceptional strength-to-weight ratio, excellent corrosion resistance (especially to chlorides), and biocompatibility.

Good for:

Why customers love it: “For applications where weight is critical but strength cannot be compromised, titanium threads are the answer. Its biocompatibility and corrosion resistance are essential for our medical and aerospace projects.”

Brass (Copper-Zinc alloy, e.g., C360) is known for its excellent machinability, good corrosion resistance, and electrical conductivity. Creates very clean threads.

Good for:

Why customers love it: “Brass machines like butter! We get perfect, sharp threads every time, which is crucial for our fluid and electrical connector applications. Plus, it looks great.”

Plastics

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic with outstanding mechanical strength, chemical resistance, wear resistance, and high-temperature stability.

Good for:

Why customers love it: “PEEK gives us metal-like performance in a lightweight plastic. Its ability to withstand harsh chemicals and high temperatures while maintaining thread integrity is incredible.”

Delrin® (Acetal / POM) is an engineering thermoplastic known for its high stiffness, low friction, excellent dimensional stability, and good machinability.

Good for:

Why customers love it: “Delrin machines incredibly well, holding tight tolerances for precise threads. Its low friction and stiffness are perfect for our moving mechanical assemblies.”

Nylon (PA, e.g., Nylon 6/6, Nylon 6) is a versatile engineering thermoplastic offering good toughness, wear resistance, and chemical resistance (especially to oils and fuels).

Good for:

Why customers love it: “Nylon threads provide a great balance of strength, toughness, and cost-effectiveness. They hold up well in applications with repeated use and moderate chemical exposure.”

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its impact resistance, toughness, rigidity, and ease of processing.

Good for:

Why customers love it: “ABS is a reliable, cost-effective material for threading general-purpose parts. It’s tough enough for everyday use and machines easily.”

Polycarbonate (PC) is a strong, impact-resistant, and transparent thermoplastic with good temperature resistance.

Good for:

Why customers love it: “The impact strength of Polycarbonate is amazing. We can thread parts that need to be both tough and transparent, which is hard to find in other materials.”

Ultem™ (PEI / Polyetherimide) is a high-performance amorphous thermoplastic offering high strength, rigidity, high-temperature resistance, broad chemical resistance, and inherent flame retardancy.

Good for:

Why customers love it: “Ultem withstands high temperatures and aggressive sterilization processes without losing thread strength or dimensional stability. It’s essential for our demanding medical and electronic applications.”

Our process makes sure you get perfect threads:

When you choose Istar Machining for thread milling, you get:

Still not sure which is better? Check out this comparison:

Feature | Thread Milling | Tapping |

Tool Cost | Higher initial cost | Lower initial cost |

Thread Quality | Very high, perfect finish | Good in soft materials only |

Material Range | Works in all materials | Limited in hard materials |

Thread Size Range | One tool for many sizes | One tool per size |

Risk of Tool Breaking | Very low | High in blind holes |

Chip Evacuation | Excellent, no clogging | Can clog in deep holes |

Speed | Slower for small threads | Faster for small, simple threads |

Complex Threads | Can make special threads | Limited to standard threads |

As a top 5 CNC machining factory in China, we provide:

Ready to get perfect threads for your next project? Contact us today for a free quote on your CNC thread milling needs!

A: Yes! That’s one of the big advantages. The tool follows a helical path without needing to reverse.

A: Almost anything! Our tools work on everything from soft plastics to hardened steel up to 62 HRC.

A: We can hold tolerances of ±0.001″ which meets aerospace and medical standards.

A: The initial tool cost may be higher, but you save money by using one tool for many thread sizes and having fewer broken tools.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or