Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

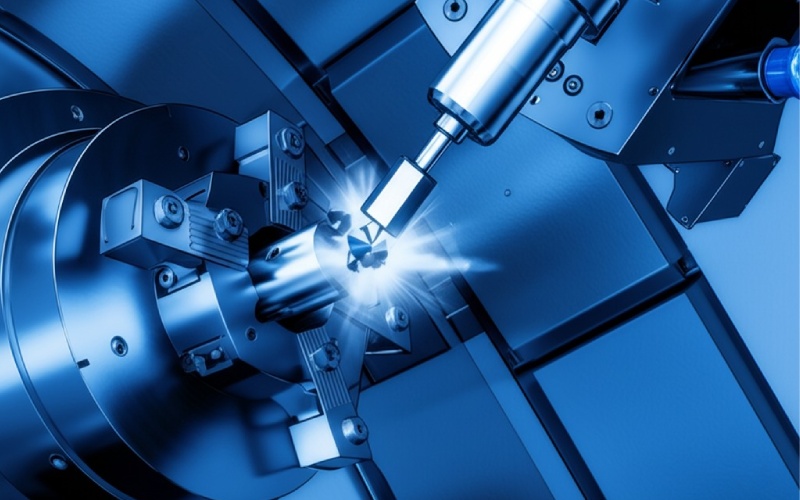

Are you looking for ways to make perfect round parts? CNC turning might be just what you need! At Istar Machining, we use smart computer-controlled machines to make super-accurate parts. Our turning services can help you create amazing products for many different industries.

Here’s what makes CNC turning special:

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

When you order parts from Istar Machining, here’s what happens:

Our turning centers have these important parts:

We can do many different operations with our machines:

Learn more about our CNC milling services which work great together with turning for complex parts.

Our CNC turning services handle a diverse range of metals and plastics.

Aluminum is a popular choice for CNC turning due to its light weight, natural corrosion resistance, and excellent machinability, making it cost-effective for many applications. It also readily accepts finishing processes like anodizing.

Common Aluminum Grades We Turn:

Typical CNC Turned Aluminum Parts: Housings, brackets, heat sinks, prototypes, automotive components, jigs & fixtures, consumer product parts.

Finishing Options: Anodizing (Clear, Color, Type III Hardcoat), Chem Film (Chromate Conversion), Powder Coating, Painting, Polishing, Brushing.

When corrosion resistance and strength are paramount, CNC turning stainless steel is often the solution. Ideal for medical, food, and marine industries, different grades offer tailored properties. Machinability varies significantly, with austenitic grades like 304/316 being more challenging than free-machining grades like 303/416.

Common Stainless Grades We Turn:

Typical CNC Turned Stainless Parts: Medical instruments, surgical tools, food processing hardware, marine fittings, valve components, fasteners, shafts, aerospace parts.

Finishing Options: Passivation (enhances corrosion resistance), Electropolishing, Mechanical Polishing, Brushing, Laser Marking.

Steel offers unmatched versatility in strength, durability, and cost. Our CNC turning services shape everything from easily machined low-carbon steels to tough, heat-treatable alloys for demanding structural and mechanical applications.

Common Steel Grades We Turn:

Typical CNC Turned Steel Parts: Shafts, axles, gears, sprockets, tooling components, fixtures, structural elements, machine parts, fasteners.

Finishing Options: Heat Treatment (Hardening, Tempering, Annealing, Case Hardening), Black Oxide Coating, Zinc Plating, Nickel Plating, Chrome Plating, Painting.

Tool steels are engineered for maximum hardness, wear resistance, and toughness, primarily used for creating tools, dies, and high-wear components. CNC turning is typically performed on the material in its softer, annealed state before it undergoes critical heat treatment processes.

Common Tool Steel Grades We Turn (Annealed):

Typical CNC Turned Tool Steel Parts: Stamping dies, punches, molds, cutting tools, shear blades, high-wear industrial components.

Finishing Options: Heat Treatment (Essential for desired properties), Surface Coatings (e.g., TiN, TiCN for enhanced wear), Precision Grinding (often post-heat treat).

Titanium stands out for its exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility. While CNC turning titanium presents challenges due to its unique thermal properties and reactivity, its performance advantages are critical in aerospace, medical, and other high-performance fields.

Common Titanium Grades We Turn:

Typical CNC Turned Titanium Parts: Aerospace structural components, engine parts, fasteners, medical implants (orthopedic, dental), surgical instruments, marine hardware, chemical processing equipment, performance automotive parts.

Finishing Options: Anodizing (Type II – primarily for color coding/identification), Passivation, Polishing, Micro-abrasive blasting.

This alloy family is selected for excellent electrical and thermal conductivity (especially copper), corrosion resistance, and good bearing properties (bronzes). CNC turning these materials is common for electrical components, plumbing fittings, bushings, and decorative items. C360 Brass, in particular, is known for its exceptional machinability.

Common Copper Alloy Grades We Turn:

Typical CNC Turned Copper Alloy Parts: Electrical contacts, terminals, connectors, heat sinks, plumbing fittings, valve bodies, bushings, bearings, decorative hardware, musical instrument parts.

Finishing Options: Polishing, Plating (Nickel, Chrome, Silver, Gold), Patination, Clear Coating/Lacquering.

CNC turning plastics offers lightweight, insulating, chemically resistant, and often low-friction alternatives to metals. We machine a variety of engineering and commodity plastics, but careful process control is needed due to factors like low melting points and thermal expansion.

Common Plastics We Turn:

Typical CNC Turned Plastic Parts: Bushings, bearings, seals, gaskets, insulators, rollers, guides, medical components, food processing parts, housings, prototypes, manifolds.

Finishing Options: Polishing, Vapor Smoothing (certain types), Annealing (for stress relief), Laser Marking/Engraving.

Our CNC turning expertise extends beyond the core categories. We also have experience with materials such as:

Your Specific Requirement: If the material you need isn’t listed, or if you’re working with a specialty alloy or customer-provided stock, please reach out. We welcome the opportunity to review your project and discuss feasibility.

Contact Us: Let our team assist you in material selection and planning for your CNC turned components.

Here’s a helpful table showing what our machines can do with different materials:

Parameter/Feature | What It Means for Your Parts | Industry Example |

Spindle Speed (Up to 10,000 RPM) | Fast cutting for smooth finishes | Automotive shafts with mirror surfaces |

Multi-Axis (2-6 Axis) | Complex shapes in one setup | Aerospace hydraulic fittings with angled holes |

Tolerance (±0.0005″) | Super precise measurements | Medical implants that fit perfectly |

Live Tooling | Can drill and mill without moving parts | Robot gear components with teeth |

Swiss-Type Turning | Ultra-precise tiny parts | Electronics connector pins smaller than a grain of rice |

Bar Feeder Systems | Non-stop production | Long runs of identical fasteners |

“The multi-axis turning capability at Istar Machining lets us make complex parts in one setup that would take multiple operations elsewhere,” explains our production manager.

When you choose Istar Machining for your turning needs, you get amazing advantages:

“Our Swiss-type lathe machines can make parts with details smaller than 0.0005 inches – that’s about 10 times thinner than a human hair!” says our lead machinist at Istar Machining.

Our turning services help make important parts for many different industries:

Our services are fully customizable to match your needs:

Working with Istar Machining gives you access to experts who can help improve your designs and save you money.

Explore our custom CNC turning solutions for specialized applications.

When you’re looking for a turning partner, here’s why Istar Machining stands out:

ISO 9001 certification for quality management AS9100 for aerospace work Full material traceability

Latest Mazak and Haas turning centers Swiss-type lathes for tiny precision parts Multi-axis machines for complex geometry

Experience with hard-to-machine metals Knowledge of special heat-resistant alloys Ability to work with medical-grade materials

Here’s exactly what happens when you work with us:

Share your ideas and requirements

Get pricing and suggestions for improvement

We program and prepare our machines

Every part is checked against specifications

Parts are finished as needed and carefully packaged

CNC turning is a cool way to make round parts. The machine holds the material and spins it really fast while tools cut into it to create the shape you want. Think of it like making pottery, but with metal and super-precise computers!

In turning, the part spins while the tool stays still. In milling, the tool spins and moves around the part. Each is better for different types of shapes.

For standard projects, we can deliver in 2-5 days. Rush orders can sometimes be completed even faster.

Almost anything! Metals, plastics, and composites. Some of our most common materials are aluminum, stainless steel, titanium, brass, and various plastics.

Our advanced machines can achieve tolerances up to ±0.0005″ on diameter, which is incredibly precise for most applications.

Yes! We handle everything from one-off prototypes to thousands of production parts.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or