Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

You’ve got a STEP file, a deadline, and one question:

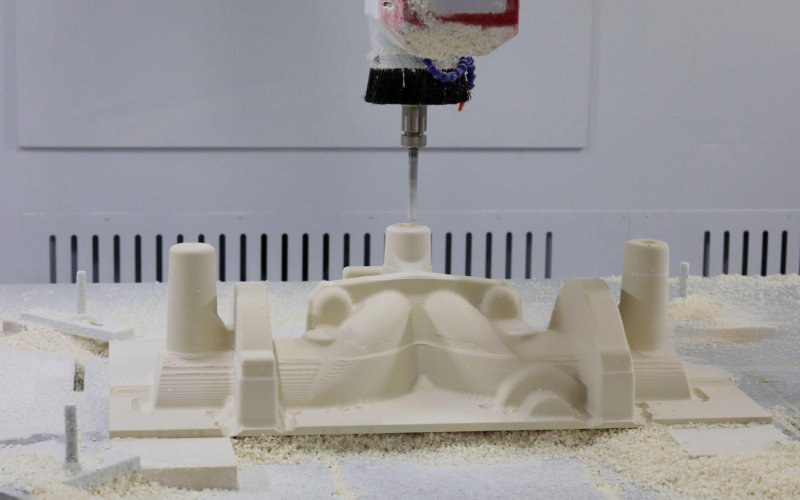

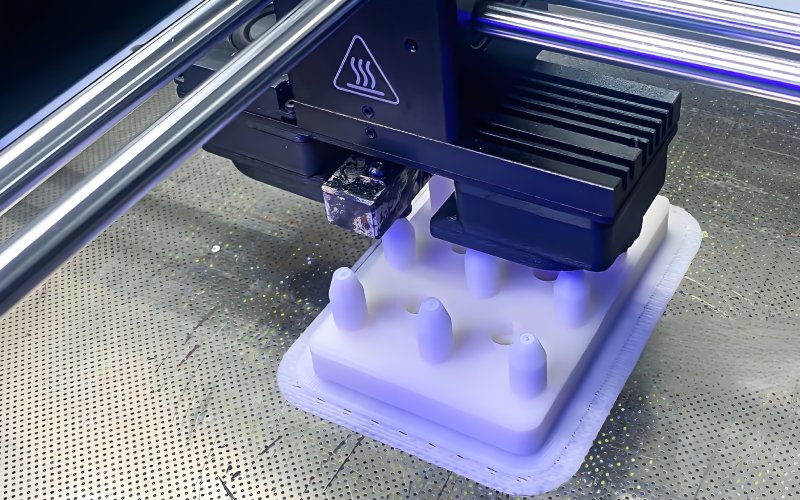

“For this one prototype, do I send it for CNC machining or 3D printing?”

Most articles say:

That’s not wrong, but it’s incomplete.

For a single prototype, the picture usually looks like this:

So price is not just “process vs process”. It’s process + risk + number of spins you expect to do.

Now let’s unpack costs the way your machinist and print bureau actually see them.

Most CNC machining quotes can be roughly reduced to this formula:

Total CNC cost = Material cost + (Machine time × Hourly rate) + Setup / programming + Finishing + Shipping

For a single part, the nasty part is that setup/programming is not diluted by volume. It lands almost fully on that first piece. That’s why many sources say a CNC prototype can be 5–10× the cost of a printed part, even when the geometry is simple.

Typical ranges you’ll see in the market:

So for one prototype, the CNC machining quote is heavily driven by:

You know this already. But it matters when you compare a $90 printed part to a $220 machined one and wonder why there’s that gap.

For outsourced 3D printing (especially plastics), the cost model is simpler:

Total 3D printing cost = Material + (Build time × Machine rate) + Post-processing + Setup/admin

Key differences vs cnc machining:

This is why many comparison guides state that for prototyping and one-offs, 3D printing tends to win on cost and lead time, with CNC machining taking over at higher volumes.

But that’s still general. Let’s put numbers to a situation you probably face weekly.

Assume:

Plausible cost build (outsourced to a mid-cost region):

Raw internal cost ≈ $78. Add shop margin and overhead and you get something like $80–100 as the quoted price for one CNC-machined ABS prototype.

Now the same part on a decent FDM machine, outsourced:

Raw internal cost ≈ $49. With margin, a realistic quote is $50–60.

These are indicative numbers, not a formal quote. But they match what many purchasing teams see.

| Cost element | CNC machining (ABS block) | FDM 3D printing (ABS-like) |

|---|---|---|

| Setup & programming | ~$40 | Included / minimal |

| Machine time | ~$30 (cut + deburr) | ~$40 (build) |

| Material | ~$8 | ~$3 |

| Post-processing | Basic (rolled into time) | ~$6 |

| Typical quoted total | $80–100 | $50–60 |

For this case, 3D printing is cheaper. Not by a thousand dollars. But enough that if you’re doing multiple iteration loops, cost adds up.

If you know you’ll print three revisions, the math tilts even more:

Now swap material and purpose:

Example cost build:

Raw internal ≈ $195 → quoted $180–220 is very normal.

Approximate structure, based on typical cost drivers: long machine time and finishing.

Total ≈ $780, then commercial realities on top. Even with aggressive pricing, you’re rarely under $400–500 for a metal-printed functional bracket of that sort.

So here, CNC machining is cheaper by a wide margin for a single prototype.

This is why, when buyers quietly compare metal printing quotes to cnc machining quotes for the same bracket, machining often wins even at a volume of one.

There are a few edge cases where CNC machining is not obviously more expensive than 3D printing even for one piece.

If your part is:

Then:

Some shops will quote aggressively on these, and the gap to printing shrinks. Especially if you’re in a region with lower CNC labor rates.

3D printing surface finishing, painting, smoothing, or support removal can easily blow out the cost.

If the print house has to:

You’re not buying “one printed part” anymore. You’re buying a chunk of manual work, and that narrows the gap with cnc machining.

One big difference from printing: CNC setup cost amortizes across the batch.

Example from a real-style cost breakdown: the first CNC part might be ~$240, while the 25th part of the same batch drops to ~$130, over 50% cheaper, just because setup is spread across more pieces.

If you expect:

Then you can think in terms of “family of prototypes” rather than a single one, and cnc machining starts to look less brutal.

You don’t always have time to model every cost term. So use simple rules.

When you send RFQs for cnc machining vs 3D printing, ask suppliers:

From the answers, you’ll see:

You’re not trying to negotiate yet. You’re trying to see which process responds better to the way your project will actually run.

If you have:

Then even if vendor pricing favors one process, your internal overhead might push the decision the other way.

Example: It might be “cheaper on paper” to 3D print outside, but if the engineering team would print it overnight in-house at near-zero marginal cost, the real decision isn’t the vendor quote.

To get clean CNC machining and 3D printing quotes for a single prototype, include:

Suppliers will quietly adjust their pricing if they know there’s likely follow-on work. That changes your real cost for today’s “single” prototype.

Stripped down:

If you’re unsure, a good pattern is:

That combination uses 3D printing where it wins on cost and speed, and cnc machining where it wins on realistic behavior.

No. It’s often cheaper for plastics and early-stage shapes, but metal parts, tight tolerances, and heavy post-processing can swing the cost toward cnc machining. Metal 3D printing in particular tends to have high machine and finishing costs.

Typical situations:

Aluminum or steel parts where you’d otherwise use metal 3D printing

Simple 2.5D geometries with short setup and predictable machining time

Cases where you know you’ll order a small batch after the first part, so setup is amortized over more pieces

Very rough, assuming common materials and moderate complexity, outsourced:

Simple plastic or aluminum parts: roughly $80–250 per part

More complex, multi-axis or tricky metals: $200–500+

The biggest drivers are machine rate, setup time, and finishing requirements, not just part size.

If you already own a 3D printer:

The cash cost per part is mostly material + a bit of labor. Machine time is “invisible” on the purchase order.

From a company viewpoint, though, printer time and engineer time still have value. Treat them as internal rates if you want a fair comparison.

Comparing outsourced printing to outsourced cnc machining is simpler: they’re both clear line items.

At minimum:

CAD file + any critical dimensions and tolerances

Material, quantity (even if it’s “1 for now, possibly 20 later”)

Notes on surfaces that matter vs surfaces that don’t

Any special inspection, certificates, or finishing

Clear inputs reduce padding in both cnc machining and 3D printing quotes, which is often a bigger cost lever than the process choice itself.