Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

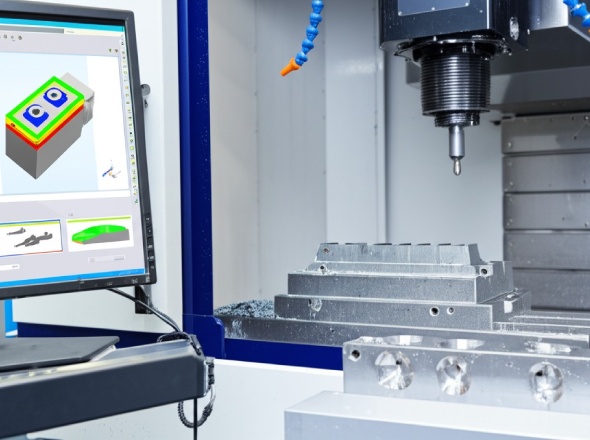

At Istar Machining, we turn raw metal into amazing parts using our top-notch CNC machines. Our team works hard to make parts that fit just right for your projects, big or small. Whether you need one part or thousands, we’ve got you covered!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

At Istar Machining, we use several methods to make your metal parts perfect:

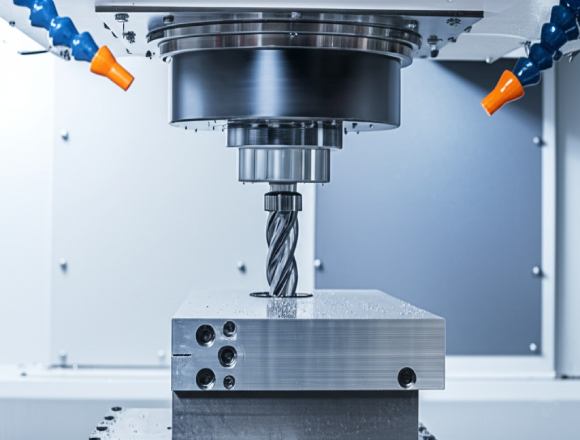

Our CNC milling machines use spinning tools to cut away metal until the part is just right. We can make flat surfaces, pockets, holes, and complex shapes.

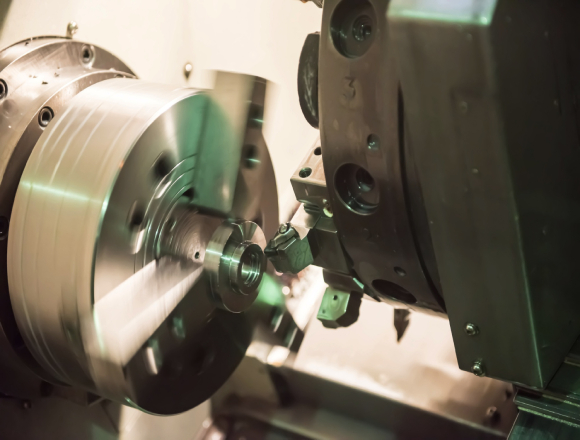

For round parts, we use CNC turning where the metal spins while tools shape it. This makes perfect cylinders, cones, and threaded parts.

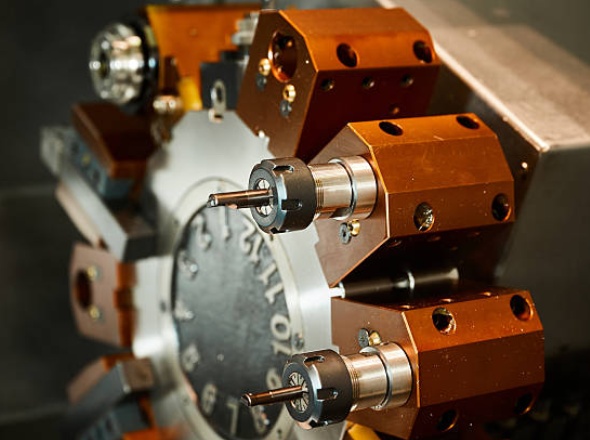

For making lots of the same part, we use machines with many spindles that can work on several pieces at once. This helps make your parts faster and keeps costs down when you need thousands of the same thing.

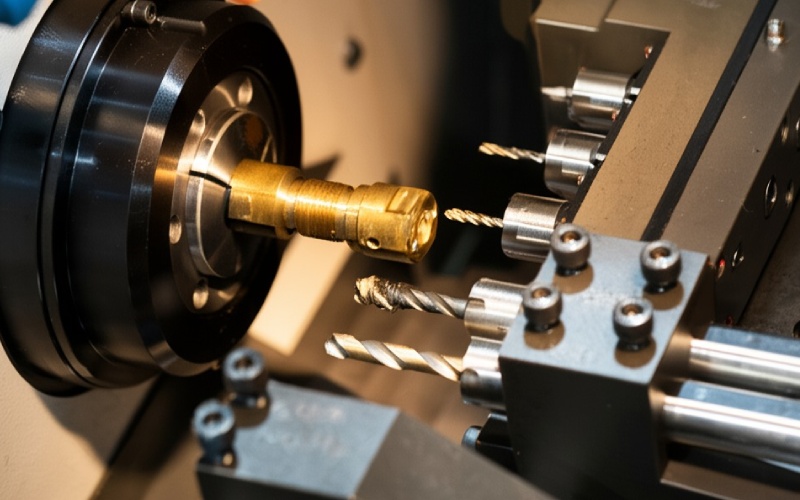

For tiny, super-precise parts, our Swiss machining tools are the answer. They can make small medical parts, pins, and electronics components with incredible accuracy.

We can machine almost any metal you need. Here’s a quick look at what we offer:

Material | Properties | Common Uses | Why Choose It |

Aluminum | Lightweight, corrosion-resistant | Aerospace parts, electronics housings | Great strength-to-weight ratio, easy to machine |

Stainless Steel | Strong, rust-resistant | Medical tools, food equipment, marine parts | Stands up to harsh conditions, looks great |

Titanium | Very strong for its weight | Aerospace components, medical implants | Incredible durability, biocompatible |

Brass | Good conductor, antimicrobial | Valves, decorative parts, music instruments | Beautiful finish, works well with liquids |

Tool Steel | Extremely hard | Molds, dies, cutting tools | Holds up to repeated use and stress |

Need custom metal machining? We can help pick the right material for your project based on how it will be used and how much it should cost.

Choosing the optimal metal involves considering several factors. We assist you by evaluating:

Our metal CNC machining helps many different industries make the things they need:

Aerospace Components

Parts require high strength-to-weight ratios and reliability. Common materials include:

Medical Devices

Requires biocompatibility, corrosion resistance, and precision:

Automotive Parts

Demands durability, strength, and often cost-effectiveness:

Electronics

Often requires thermal management and electrical properties:

At Istar Machining, we check everything twice to make sure it’s perfect. Our quality systems include:

Each part we make gets checked against your design before we ship it. If it’s not perfect, we don’t send it!

At Istar Machining, we use the latest tools to make better parts:

Our precision CNC machining uses these tools to make parts better and faster than old-fashioned methods.

High Precision & Tight Tolerances: We can achieve tolerances as tight as ±0.001″ (0.025mm), ensuring parts fit and function perfectly.

Surface Finishes: We offer various surface finishes, from standard machined finishes to highly polished or specific roughness (Ra) requirements.

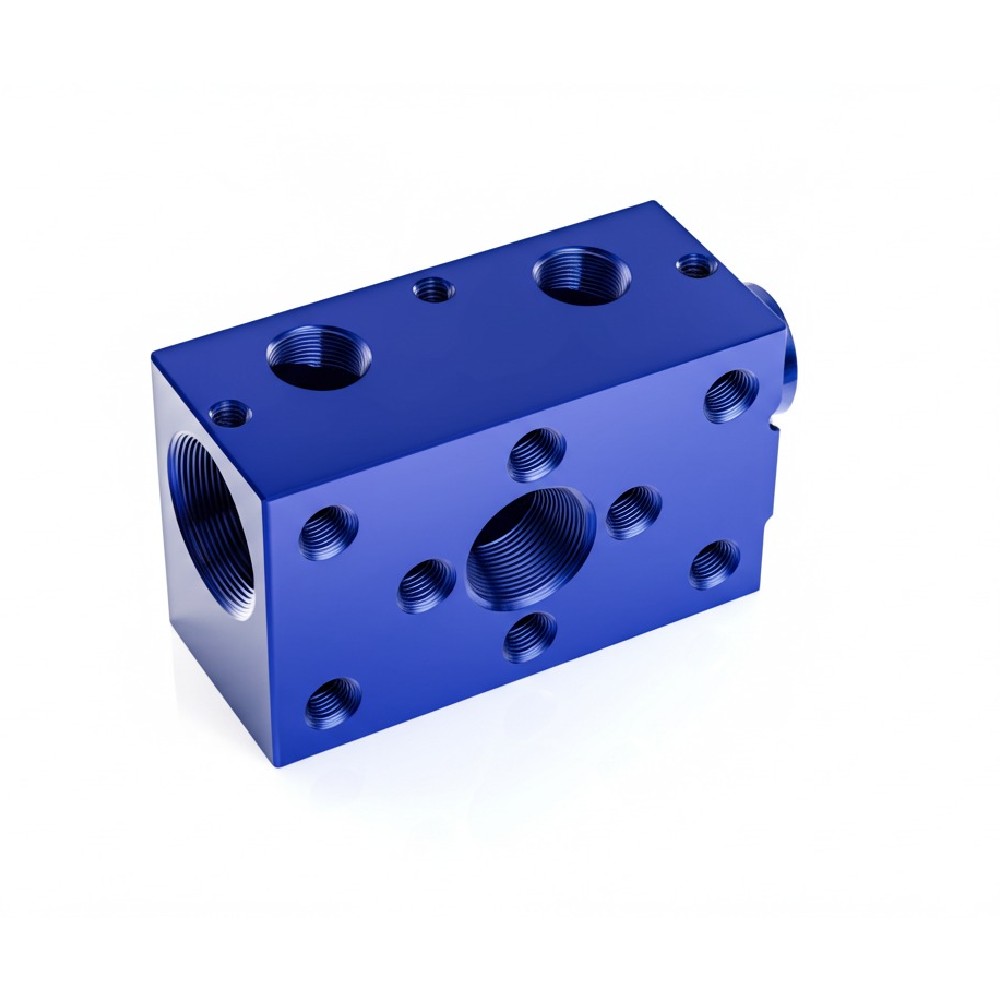

Anodized Aluminum: We provide anodizing services for aluminum parts, creating a durable, corrosion-resistant, and often colored surface finish.

Complex Geometries: Utilizing advanced techniques like 5-axis machining, we can produce highly complex shapes and features efficiently.

We’re not just any metal shop – we’re experts who care about quality. Here’s why people pick us:

(±0.001mm) checked with special measuring tools

with most jobs done in less than a week

over 50 different kinds!

that work 20% faster thanks to computer brains

to help with your design questions

Getting parts from Istar Machining is simple:

(CAD files work best)

(usually in less than 24 hours)

to make sure it can be made efficiently

once you approve

ensure everything meets specs

Ready to get metal parts made just how you need them? Here’s how to begin:

Our team at Istar Machining is excited to help bring your ideas to life with our metal CNC machining expertise!

Metal CNC machining is when computers control tools that cut metal into exact shapes. Think of it like a robot sculptor that can make the same perfect part over and over again. Our machines at Istar Machining are super smart and can make parts that are as thin as a human hair!

Our CNC machining service uses the best tools and newest technology to create parts that meet all your needs.

Our advanced CNC machines achieve tolerances as tight as ±0.001mm for most metals. This exceptional precision comes from our combination of state-of-the-art equipment, quality control procedures, and skilled machinists who verify dimensions using coordinate measuring machines (CMMs).

There’s no minimum order requirement at Istar Machining. We can produce a single prototype or thousands of production parts. Our flexible manufacturing setup allows us to scale efficiently from one-off custom parts to high-volume production runs.

Turnaround times vary based on complexity, quantity, and current production schedule. Simple parts can often be delivered in 1-5 days with our rapid CNC machining service. Standard production typically takes 1-3 weeks, while complex projects may require 3-4 weeks. We also offer expedited services for urgent needs.

Absolutely! Our design for manufacturability (DFM) review is included with every quote. Our engineers will suggest modifications that can reduce costs, improve quality, or enhance functionality while maintaining your design intent. This collaborative approach ensures you get the best possible parts.

We provide numerous finishing services including anodizing, powder coating, painting, polishing, brushing, plating (nickel, chrome, gold), heat treatment, bead blasting, and passivation. These treatments enhance appearance, corrosion resistance, wear properties, and other functional characteristics.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or