Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for parts that can stand up to tough jobs but won’t weigh you down? At Istar Machining, we turn titanium into amazing parts using our top-notch CNC machining service. Titanium is a super-strong metal that’s much lighter than steel but just as tough. Let’s explore why titanium CNC machining might be perfect for your next project!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

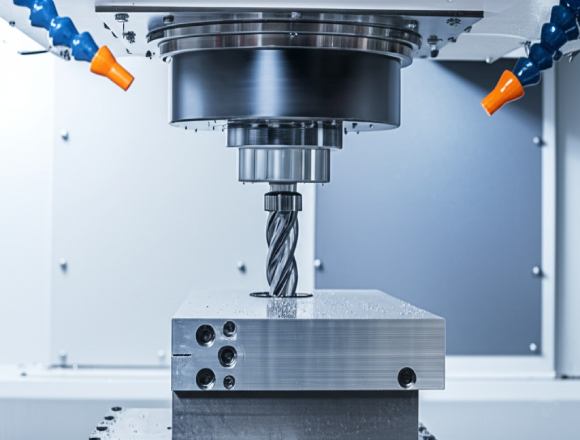

At Istar Machining, we use special methods to work with titanium:

Our CNC milling titanium process uses special cutting tools and speeds to create complex shapes without damaging the material. We can make parts with:

Deep pockets that keep material strength

Thin walls that don't warp

Complex curves that fit perfectly with other parts

Threaded holes that hold strong

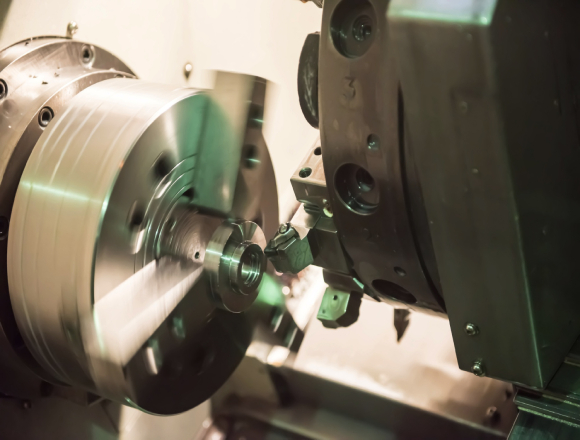

For round parts, our titanium turning process creates perfect cylinders, cones, and threaded sections. We make:

Precision shafts for medical devices

Custom fasteners that won't come loose

Bearing surfaces that last for years

Transition pieces between different systems

After machining, we can add these finishing touches:

Anodizing: Adds color and protection

Passivation: Creates an extra-strong protective layer

Bead Blasting: Creates a consistent matte finish

Polishing: Makes surfaces mirror-smooth for medical use

Laser Marking: Adds permanent part numbers or logos

Different materials are better for different jobs. Here’s what works best:

This is the softest titanium. It bends well. It can be welded.

Good for:

This is the most common pure titanium. It is a bit stronger than Grade 1.

Good for:

This is the most used titanium for CNC. It is very strong but still light.

This is the most used titanium for CNC. It is very strong but still light.

Good for:

This grade is used in titanium CNC machining all the time.

This grade has palladium in it. This makes it good with acid and salt water.

Good for:

ELI means “Extra Low Interstitials.” This is the medical grade. It can go in your body.

Good for:

This grade is good for high heat. It has molybdenum and nickel in it.

Good for:

Here’s how the grades stack up:

| Grade | Strength (MPa) | Heat Limit | Cost ($/kg) | Best Use |

|---|---|---|---|---|

| 1 | 240-345 | Medium | 40−60 | Bending |

| 2 | 345-550 | Medium | 50−70 | General |

| 5 | 895-930 | High | 80-120 | Strength |

| 7 | 345-550 | Medium | 90-130 | Chemicals |

| 23 | 828-875 | High | 150-200 | Medical |

| 12 | 690-860 | Very High | 70-100 | Hot parts |

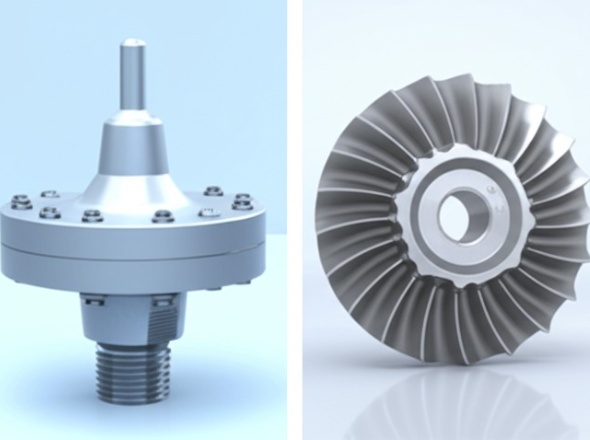

At Istar Machining, we can make almost any titanium part you can imagine:

Not sure if titanium is right for your project? Here’s how it compares:

Property | Titanium | Aluminum | Stainless Steel |

Strength | Very High | Medium | High |

Weight | Medium | Very Light | Heavy |

Corrosion Resistance | Excellent | Good | Good |

Heat Resistance | Excellent | Poor | Good |

Cost | Higher | Lower | Medium |

Machinability | Challenging | Easy | Medium |

While aluminum CNC machining and steel CNC machining are great for many projects, titanium offers the best combination of strength, weight, and durability.

Years of successful titanium projects

Latest 5-axis machines and tooling

Rigorous testing and certification

Expert advice and on-time delivery

Competitive pricing without compromising quality

When you work with Istar Machining, here’s what happens:

We look at your design and suggest ways to make it better for titanium

Our experts create special cutting instructions for titanium

After approval, we make all your parts with consistent quality

We can add special treatments like anodizing (color coating)

Every part is checked to make sure it's perfect

If you need titanium parts that perform under pressure, Istar Machining is your partner for success. We combine cutting-edge technology with decades of experience to deliver custom titanium machining that exceeds expectations.

Request a quote today and discover why leading aerospace, medical, and industrial companies trust us with their most challenging titanium projects. Upload your CAD file for immediate review and pricing.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or